Aure Chemical Delivers Excellence in High-Purity Dichlorodimethylsilane (CAS 75-78-5)

Aure Chemical is a premier global supplier of high-quality Dichlorodimethylsilane (Me₂SiCl₂), more commonly known as Dimethyldichlorosilane (DMDCS). Identified by its CAS number 75-78-5, this organosilicon compound is a colorless, fuming liquid with a pungent odor. Dichlorodimethylsilane stands as the single most important monomer in the vast silicone industry. It is the fundamental building block for the synthesis of a wide array of silicone polymers, fluids, resins, and rubbers, which are renowned for their exceptional thermal stability, water repellency, electrical insulation, and low surface tension. Its versatile properties make it indispensable in countless applications, from high-performance sealants and coatings to lubricants, personal care products, and medical devices. Due to its reactivity with moisture and corrosive nature, handling and transportation of Dichlorodimethylsilane require meticulous care and adherence to strict safety protocols. Aure Chemical's unwavering commitment to excellence ensures that our Dichlorodimethylsilane meets the stringent purity and performance requirements for your most demanding industrial applications, guaranteeing consistency, safety, and reliability for your silicone manufacturing needs.

Basic Information of Dichlorodimethylsilane

Dichlorodimethylsilane (CAS No. 75-78-5) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 75-78-5 |

|---|

| EC No.: | 200-901-0 |

|---|

| Linear Formula: | (CH₃)₂SiCl₂ |

|---|

| Molecular Weight: | 129.06 |

|---|

| Appearance: | Colorless, fuming liquid. |

|---|

| Odor: | Pungent odor. |

|---|

| Melting Point: | -76 °C |

|---|

| Boiling point: | 70 °C(lit.) |

|---|

| Density: | 1.333 g/mL at 20 °C |

|---|

| Reactivity: | Reacts vigorously with water (hydrolyzes to form polydimethylsiloxanes and hydrochloric acid), alcohols, and other active hydrogen compounds. |

|---|

| Flammability: | Flammable liquid and vapor. |

|---|

| Corrosivity: | Highly corrosive to metals in the presence of moisture and to organic tissues. |

|---|

| RIDADR: | UN 1162 3,8/PG 2 |

|---|

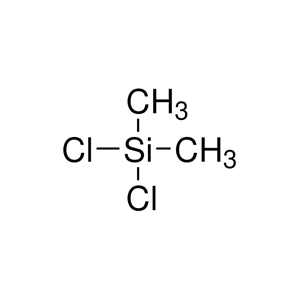

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Dichlorodimethylsilane ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse industrial needs, while prioritizing uncompromising safety in handling and logistics.

Primary Applications of Dichlorodimethylsilane

Dichlorodimethylsilane's pivotal role as a monomer in silicone chemistry underpins its widespread industrial importance:

Silicone Polymer Manufacturing:

It is the primary precursor for the synthesis of polydimethylsiloxanes, which are the backbone of almost all silicone products. Through hydrolysis and condensation, it forms linear and cyclic silicone polymers that can be further processed into fluids, resins, and elastomers.

Silicone Fluids:

Used in the production of silicone oils and fluids, which find applications as lubricants, hydraulic fluids, damping fluids, defoamers, and in personal care products (e.g., shampoos, conditioners, cosmetics) due to their unique spreading and non-greasy feel.

Silicone Rubbers (Elastomers):

A critical component in the synthesis of silicone rubbers, known for their excellent flexibility, high-temperature stability, and resistance to environmental degradation. These are used in sealants, gaskets, automotive parts, medical devices, and electronics.

Silicone Resins:

Used to produce silicone resins, which provide durable, heat-resistant, and water-repellent properties to coatings, paints, and electrical insulation materials.

Sealants and Adhesives:

Forms the basis for various silicone-based sealants and adhesives, offering superior weather resistance, flexibility, and longevity in construction, automotive, and electronics industries.

Surface Treatment & Water Repellency:

Can be used directly or as an intermediate in the production of chemicals for surface treatment, imparting water-repellent properties to textiles, paper, masonry, and glass surfaces.

Why Choose Aure Chemical for Your Dichlorodimethylsilane Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Dichlorodimethylsilane requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Dichlorodimethylsilane is manufactured to stringent purity specifications, crucial for optimizing the performance and properties of the resulting silicone polymers and finished products.

Uncompromising Safety & Compliance: Given the hazards associated with Dichlorodimethylsilane, Aure Chemical maintains world-class safety standards. Our manufacturing, storage, and transportation protocols are meticulously designed to adhere strictly to international safety regulations and best practices for handling highly reactive and flammable liquids.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this critical chemical to your facilities worldwide, with specialized logistics for hazardous liquids.

Expert Technical & Safety Support: Our dedicated team of experienced chemists and highly trained safety specialists is readily available to offer comprehensive guidance on product application, stringent safe handling procedures, emergency response planning, and optimal storage conditions for Dichlorodimethylsilane.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and the responsible management of hazardous chemicals.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Dichlorodimethylsilane. We're ready to support your most demanding and innovative silicone manufacturing processes with an unwavering commitment to safety and excellence.

Dichlorodimethylsilane (CAS 75-78-5) — Frequently Asked Questions

What is Dichlorodimethylsilane (DCDMS)?

Dichlorodimethylsilane ((CH3)2SiCl2, CAS 75-78-5) is a chlorosilane — a moisture-sensitive organosilicon reagent commonly used as a building block for silicones and silane-modified intermediates.

What are the main uses of DCDMS?

It is primarily used as a precursor for silicone polymers, silanol-terminated oligomers, chlorosilane intermediates, and specialty surface treatments in coatings, sealants and electronics. It also serves as a functionalizing agent in some fine-chemical processes.

What are the key physical properties?

Typical properties: colorless to pale liquid, pungent odor, relatively low boiling point, and it is moisture sensitive. Exact numbers (bp, density, vapor pressure) depend on grade — always check the product datasheet.

Is DCDMS moisture sensitive / does it react with water?

Yes. DCDMS hydrolyses on contact with water (including humid air), producing hydrochloric acid (HCl) and silanols. Handle and store it under dry, inert atmosphere (e.g., N2) to avoid hydrolysis.

Is Dichlorodimethylsilane flammable?

It can be combustible and may produce flammable vapors. Treat it as a flammable/combustible organic liquid — keep away from ignition sources and follow the SDS guidance for flash point and fire precautions.

What are the health hazards of DCDMS?

Exposure can cause respiratory irritation, severe eye and skin irritation, and corrosive effects due to HCl formed on hydrolysis. Inhalation, ingestion or skin contact should be avoided; use appropriate PPE.

What personal protective equipment (PPE) is recommended?

Use chemical-resistant gloves (e.g., butyl or Viton where suitable), splash goggles or face shield, chemical-resistant clothing, and work in a fume hood or with local exhaust. Use respiratory protection when ventilation is inadequate (see SDS).

How should DCDMS be stored?

Store in a cool, dry, well-ventilated area away from moisture and incompatible substances (water, alcohols, bases). Keep containers tightly sealed, preferably under inert gas. Use corrosion-resistant secondary containment.

How is DCDMS packaged and transported?

Supplied in moisture-tight, corrosion-resistant containers (glass bottles with PTFE caps for small volumes; lined metal drums or specially lined containers for bulk). Transport must follow local/regional dangerous-goods regulations — consult SDS and carrier for correct UN number/packing instructions for your shipment.

What should I do in case of a spill?

Evacuate the area, ventilate, and avoid breathing vapors. Stop leak if safe. Do not use water to clean up; absorb with dry, inert material (e.g., dry sand, vermiculite) and collect into dry sealed containers for hazardous waste disposal. Refer to SDS for emergency measures.

What are recommended disposal methods?

Dispose of DCDMS and contaminated materials as hazardous chemical waste per local/regional regulations. Do not release to sewer or waterways. Consult local waste authorities or the SDS for approved disposal pathways.

Can Aure Chemical supply Dichlorodimethylsilane?

Yes — contact Aure Chemical sales for available grades, packaging options, COA, SDS and shipping support. Provide required documentation and handling instructions for safe logistics.

Where can I find the authoritative safety information?

Always consult the product Safety Data Sheet (SDS) and applicable local regulations. The SDS contains definitive info on classification, UN number, PPE, first aid, and transport instructions for the exact grade and batch.

Related Articles

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Corrosive (GHS05), Acute Toxicity (GHS06)

Hazard Statements: Highly flammable liquid and vapor; causes severe skin burns and eye damage; toxic if inhaled.

UN Number: UN 1162

Hazard Class: 3 (Flammable Liquids), 8 (Corrosive)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity