Discover Aure Chemical's Premium Dichloromethylsilane (CAS 75-54-7) Supply

Aure Chemical is a premier global supplier of high-quality Dichloromethylsilane (CH₃SiCl₂), also commonly known as Methyldichlorosilane. Identified by its CAS number 75-54-7, this organosilicon compound is a colorless liquid with a pungent, irritating odor. Dichloromethylsilane is a highly versatile and essential chemical intermediate, primarily utilized in the production of a wide range of silicon-containing materials. It serves as a crucial building block for various silicones, including resins and elastomers, as well as for the synthesis of specialized silanes and surface treatment agents that impart hydrophobic or other desirable properties to various substrates. Due to its reactivity with moisture and corrosive nature, handling and transportation of Dichloromethylsilane require meticulous care and adherence to strict safety protocols. Aure Chemical's unwavering commitment to excellence ensures that our Dichloromethylsilane meets the demanding purity and performance requirements for your most critical industrial applications, guaranteeing consistency, safety, and reliability for your advanced material needs.

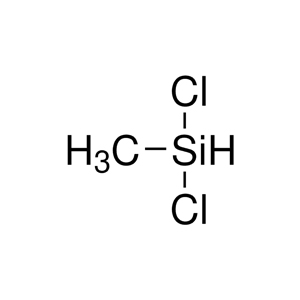

Basic Information of Dichloromethylsilane

Dichloromethylsilane (CAS No. 75-54-7) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 75-54-7 |

|---|

| EC No.: | 200-877-1 |

|---|

| Linear Formula: | CH₃SiCl₂ |

|---|

| Molecular Weight: | 115.03 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Pungent, irritating odor. |

|---|

| Melting Point: | -93 °C |

|---|

| Boiling point: | 41 °C(lit.) |

|---|

| Density: | 1.105 g/mL at 25 °C(lit.) |

|---|

| Reactivity: | Highly reactive with water (hydrolyzes to form siloxanes and hydrochloric acid), alcohols, and other active hydrogen compounds. Readily undergoes hydrosilylation reactions. |

|---|

| Flammability: | Highly flammable liquid and vapor. |

|---|

| Corrosivity: | Corrosive to metals in the presence of moisture and to organic tissues. |

|---|

| RIDADR: | UN 1242 3,8/PG 1 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Dichloromethylsilane ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse industrial needs, while prioritizing uncompromising safety in handling and logistics.

Primary Applications of Dichloromethylsilane

Dichloromethylsilane's versatile reactivity makes it a crucial intermediate in the synthesis of a wide range of organosilicon compounds:

Silicone Polymer Production:

It is a key building block in the production of various silicone polymers, including resins and elastomers with tailored properties for diverse applications such as adhesives, sealants, and coatings.

Synthesis of Functional Silanes:

Dichloromethylsilane is used as an intermediate in the synthesis of other functional silanes, which serve as coupling agents, crosslinkers, and surface modifiers in various industrial processes.

Surface Treatment Agents:

It is employed in the production of surface treatment agents that impart hydrophobic, oleophobic, or other specialized properties to glass, textiles, ceramics, and other materials.

Hydrosilylation Reactions:

The Si-H bond in Dichloromethylsilane makes it a valuable reagent for hydrosilylation reactions, where it can add across unsaturated bonds to introduce silicon-containing functional groups into organic molecules.

Intermediate for Specialty Chemicals:

It serves as a versatile intermediate in the synthesis of a wide range of other specialty organosilicon compounds used in various niche applications.

Why Choose Aure Chemical for Your Dichloromethylsilane Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Dichloromethylsilane requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Dichloromethylsilane is manufactured to stringent purity specifications, crucial for achieving optimal results in sensitive silicone and silane synthesis applications.

Uncompromising Safety & Compliance: Given the hazards associated with Dichloromethylsilane, Aure Chemical maintains world-class safety standards. Our manufacturing, storage, and transportation protocols are meticulously designed to adhere strictly to international safety regulations and best practices for handling highly flammable and corrosive liquids.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this critical chemical to your facilities worldwide, with specialized logistics for hazardous materials.

Expert Technical & Safety Support: Our dedicated team of experienced chemists and highly trained safety specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, emergency response planning, and optimal storage conditions for Dichloromethylsilane.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and the responsible management of hazardous chemicals.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Dichloromethylsilane. We're ready to support your most demanding and innovative material science processes with an unwavering commitment to safety and excellence.

FAQ

What is Dichloromethylsilane?

Dichloromethylsilane (chemical formula CH2Cl2SiH) is a colorless, flammable liquid used as an intermediate in organosilicon chemistry. It is widely applied in the synthesis of siloxanes, silicone resins, and coupling agents.

What are the main hazards of Dichloromethylsilane?

It is classified as a flammable liquid and corrosive substance. It reacts violently with water, releasing hydrochloric acid gas, and causes severe skin burns and eye damage. Harmful if inhaled.

How should Dichloromethylsilane be stored?

Store in a tightly sealed container under an inert gas blanket (e.g., nitrogen). Keep in a cool, dry, and well-ventilated area, away from heat, sparks, and moisture. Segregate from incompatible chemicals such as oxidizers, alcohols, and bases.

What packaging options are available?

Commercial supply is usually in 25 L or 200 L steel drums with corrosion-resistant linings. For laboratory use, smaller volumes may be packaged in sealed amber glass bottles or PTFE-lined containers.

What is the UN number and transport classification?

UN 1162 — Dichloromethylsilane. Classified as Class 3 (Flammable liquids) with subsidiary risk Class 8 (Corrosive). Packing group II. Transportation must comply with ADR/RID, IMDG, and IATA regulations.

What should I do in case of a spill or exposure?

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Corrosive (GHS05), Acute Toxicity (GHS06)

Hazard Statements: Highly flammable liquid and vapor; causes severe skin burns and eye damage; toxic if inhaled.

UN Number: UN 1242

Hazard Class: 3 (Flammable Liquids), 8 (Corrosive)

Packing Group: I

GHS02: Flammable

GHS02: Flammable GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity