Discover Aure Chemical's Premium Hexamethyldisilazane (HMDS) Supply

Aure Chemical is a leading supplier of Hexamethyldisilazane (HMDS), a versatile organosilicon compound crucial for a wide range of industrial and specialty applications. We provide high-purity HMDS, ensuring consistent quality for your demanding processes.

Basic Information of Hexamethyldisilazane

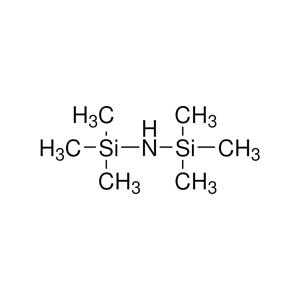

Hexamethyldisilazane (HMDS CAS 999-97-3), also known as bis(trimethylsilyl)amine, is an organic silicon compound with the chemical formula [(CH₃)₃Si]₂NH. It's a clear, colorless liquid with a characteristic ammonia-like odor. Its unique chemical structure, featuring two trimethylsilyl groups bonded to a nitrogen atom, makes it an excellent silylating agent, meaning it can introduce trimethylsilyl groups into other molecules.

| CAS No.: | 999-97-3 |

|---|

| EC No.: | 213-668-5 |

|---|

| Linear Formula: | [(CH₃)₃Si]₂NH |

|---|

| Molecular Weight: | 161.39 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Melting Point: | -78 °C |

|---|

| Boiling point: | 125 °C (lit.) |

|---|

| Density: | 0.774 g/mL at 25 °C(lit.) |

|---|

| Flash Point: | 57.2 °F |

|---|

| RIDADR: | UN 3286 3, 8, 6.1/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Key Features and Benefits

High Purity: Our HMDS is manufactured to strict quality standards, ensuring minimal impurities for optimal performance.

Excellent Silylating Agent: It efficiently adds trimethylsilyl groups to hydroxyl (-OH), amino (-NH), and thiol (-SH) functionalities, converting them into more volatile or stable derivatives.

Effective Water Scavenger: HMDS reacts readily with water, making it an excellent drying agent in moisture-sensitive reactions and processes.

Versatile Reactant: Its reactivity allows for its use in various chemical syntheses.

Applications of HMDS

Hexamethyldisilazane (HMDS) plays a critical role across numerous industries due to its diverse properties:

Pharmaceutical Synthesis: Widely used as a silylating agent and protecting group in the synthesis of active pharmaceutical ingredients (APIs), including antibiotics and steroids. It helps to enhance solubility, facilitate reactions, and protect sensitive functional groups during complex syntheses.

Semiconductor Industry: Crucial as an adhesion promoter in photolithography processes. It treats silicon wafers to improve the adhesion of photoresists, leading to better pattern definition and yield in microchip manufacturing.

Gas Chromatography (GC): Employed for derivatization of polar compounds (e.g., alcohols, amines, carboxylic acids) to make them more volatile and thermally stable, enabling their analysis by GC.

Rubber and Plastics: Used as a surface modifier to improve the compatibility of inorganic fillers (like silica) with polymer matrices, enhancing the mechanical properties of rubber and plastic products.

Silicone Chemistry: Serves as a raw material or intermediate in the production of various silicone compounds and polymers.

Hydrophobic Coatings: Utilized to create hydrophobic (water-repellent) surfaces on glass, textiles, and other materials.

Why Choose Aure Chemical for HMDS?

At Aure Chemical, we are committed to providing top-quality chemical products and exceptional customer service. Our HMDS product stands out due to:

Reliable Supply: Consistent availability to meet your production demands.

Quality Assurance: Rigorous quality control processes ensure product purity and performance.

Technical Support: Our knowledgeable team is ready to assist with product information and application guidance.

Competitive Pricing: We offer cost-effective solutions without compromising on quality.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Corrosive (GHS05), Acute Toxicity (GHS06)

Hazard Statements: Highly flammable liquid and vapor; causes severe skin burns and eye damage; harmful if swallowed or inhaled.

UN Number: UN 3286

Hazard Class: 3 (Flammable Liquids), 8 (Corrosive), 6.1 (Toxic)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity