Aure Chemical Delivers Excellence in Octamethylcyclotetrasiloxane (D4)

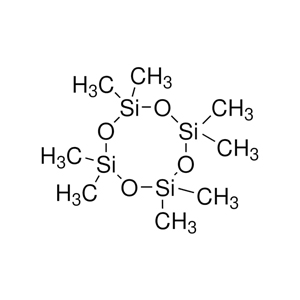

Octamethylcyclotetrasiloxane (D4) is a cyclic siloxane compound with the chemical formula [(CH₃)₂SiO]₄. It features four repeating dimethylsiloxane units in a stable ring structure. D4 is typically a clear, colorless, and odorless volatile silicone fluid. Its unique blend of low viscosity, high volatility, excellent spreadability, and a non-greasy feel makes it a foundational ingredient in numerous applications, particularly within the personal care sector, as well as a crucial building block in silicone chemistry.

Basic Information of Octamethylcyclotetrasiloxane

| CAS No.: | 556-67-2 |

|---|

| EC No.: | 209-136-7 |

|---|

| Linear Formula: | [(CH₃)₂SiO]₄ |

|---|

| Molecular Weight: | 296.62 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Melting Point: | 17-18 °C (lit.) |

|---|

| Boiling point: | 175-176 °C (lit.) |

|---|

| Density: | 0.956 g/mL at 25 °C (lit.) |

|---|

| Volatility: | Highly volatile, evaporates cleanly without leaving residue. |

|---|

| Feel: | Imparts a smooth, soft, and non-greasy feel. |

|---|

| Stability: | Chemically inert and thermally stable. |

|---|

| RIDADR: | UN 1993 3/PG 3 |

|---|

| Chemical Structure: |  |

|---|

Applications of Octamethylcyclotetrasiloxane (D4)

Octamethylcyclotetrasiloxane (D4) is a versatile ingredient, widely employed across various sectors due to its unique physical and chemical properties:

Why Choose Aure Chemical's D4?

Partnering with Aure Chemical for your Octamethylcyclotetrasiloxane (D4) supply offers several advantages:

Superior Purity: We provide high-purity D4, essential for consistent performance in your sensitive formulations and polymerization processes.

Consistent Quality: Our stringent quality control processes ensure that every batch of D4 meets the highest industry standards.

Reliable Supply: With robust manufacturing capabilities and efficient inventory management, we guarantee a stable and timely supply to support your production demands.

Dedicated Technical Support: Our team of experts is available to offer comprehensive technical data and assistance, helping you optimize your product formulations.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Health Hazard (GHS08), Environmental Hazard (GHS09)

Hazard Statements: Flammable liquid and vapor; suspected of damaging fertility or the unborn child; toxic to aquatic life with long lasting effects.

UN Number: UN 1993

Hazard Class: 3 (Flammable Liquids)

Packing Group: III

GHS02: Flammable

GHS02: Flammable GHS08: Health hazard

GHS08: Health hazard GHS09: Environmental hazard

GHS09: Environmental hazard