Explore Top-Quality Silicon Tetrachloride (CAS 10026-04-7) with Aure Chemical

Aure Chemical is a premier global supplier of high-quality Tetrachlorosilane (SiCl₄), most commonly referred to as Silicon Tetrachloride. Identified by its CAS number 10026-04-7, this inorganic compound is a colorless, fuming liquid with a pungent odor. Silicon Tetrachloride is a cornerstone chemical in several high-tech industries due to its versatility and high purity potential. It's a critical precursor for the production of ultra-pure silicon used extensively in semiconductors and solar cells. Furthermore, it's the main raw material for manufacturing fumed silica, an indispensable additive for diverse industries ranging from paints and coatings to pharmaceuticals and cosmetics. Its broad utility extends to the synthesis of specialty silicones and optical fibers, demanding rigorous quality control. Due to its reactivity with moisture and corrosive nature, handling and transportation of Silicon Tetrachloride require meticulous care and adherence to strict safety protocols. Aure Chemical's unwavering commitment to excellence ensures our Silicon Tetrachloride meets the demanding purity and performance requirements for your most critical industrial applications, guaranteeing consistency, safety, and reliability.

Basic Information of Silicon Tetrachloride

Silicon Tetrachloride (CAS No. 10026-04-7) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 10026-04-7 |

|---|

| EC No.: | 233-054-0 |

|---|

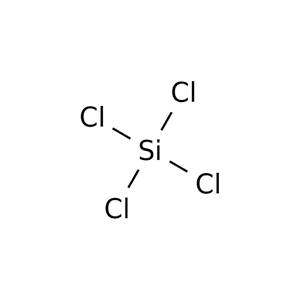

| Linear Formula: | SiCl₄ |

|---|

| Molecular Weight: | 169.9 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Pungent odor. |

|---|

| Melting Point: | −70 °C(lit.) |

|---|

| Boiling point: | 57.6 °C(lit.) |

|---|

| Density: | 1.483 g/mL at 25 °C(lit.) |

|---|

| Reactivity: | Reacts vigorously and exothermically with water (hydrolyzes to form silicic acid and hydrochloric acid). |

|---|

| Flammability: | Highly corrosive to metals in the presence of moisture and to organic tissues. |

|---|

| Corrosivity: | Unlike some other chlorosilanes, it is non-flammable. |

|---|

| RIDADR: | UN 1818 8/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Silicon Tetrachloride ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse industrial needs, while prioritizing uncompromising safety in handling and logistics.

Primary Applications of Silicon Tetrachloride

Silicon Tetrachloride's unique properties and high reactivity make it an indispensable compound with extensive applications across high-tech and industrial sectors:

Semiconductor and Solar Grade Silicon Production:

Its most significant application is in the manufacturing of ultra-pure silicon (polysilicon). It serves as a precursor in the Siemens process for chemical vapor deposition (CVD), yielding silicon that meets the rigorous purity demands of the semiconductor industry for microchips, integrated circuits, and high-efficiency solar cells.

Fumed Silica Production:

Silicon Tetrachloride is the primary raw material for producing fumed silica (pyrogenic silica). This ultrafine, high-surface-area silica is crucial as a thickening agent, thixotropic agent, abrasive, and anti-caking agent in paints, coatings, adhesives, sealants, pharmaceuticals, and cosmetics.

Optical Fiber Manufacturing:

High-purity Silicon Tetrachloride is used in the production of optical fibers for telecommunications. It's vaporized and oxidized to form layers of highly pure silicon dioxide within the fiber, essential for light transmission.

Specialty Silicone Synthesis:

It acts as a key intermediate in the synthesis of various specialty silicone compounds, including certain silicone resins and polymers with specific cross-linking requirements or unique properties.

Chemical Intermediate:

Serves as a versatile chemical intermediate in the synthesis of other silicon-containing compounds, including various silanes and organosilicon derivatives for niche applications.

Why Choose Aure Chemical for Your Silicon Tetrachloride Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Silicon Tetrachloride requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Silicon Tetrachloride is manufactured to stringent purity specifications, critical for applications like semiconductor-grade silicon and optical fiber production where even trace impurities can significantly impact performance.

Uncompromising Safety & Compliance: Given the hazards associated with Silicon Tetrachloride, Aure Chemical maintains world-class safety standards. Our manufacturing, storage, and transportation protocols are meticulously designed to adhere strictly to international safety regulations and best practices for handling corrosive and moisture-sensitive liquids.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this critical chemical to your facilities worldwide, with specialized logistics for hazardous materials.

Expert Technical & Safety Support: Our dedicated team of experienced chemists and highly trained safety specialists is readily available to offer comprehensive guidance on product application, stringent safe handling procedures, emergency response planning, and optimal storage conditions for Silicon Tetrachloride.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and the responsible management of hazardous chemicals.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Silicon Tetrachloride. We're ready to support your most demanding and innovative high-tech manufacturing processes with an unwavering commitment to safety and excellence.

Hazards Classification

GHS Classification: Corrosive (GHS05), Acute Toxicity (GHS06), Exclamation Mark (GHS07)

Hazard Statements: Causes severe skin burns and eye damage; toxic if inhaled; may cause respiratory irritation.

UN Number: UN 1818

Hazard Class: 8 (Corrosive)

Packing Group: II

GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity GHS07: Exclamation mark

GHS07: Exclamation mark