Aure Chemical Delivers Excellence in Sodium p-Styrenesulfonate

Aure Chemical is a premier global supplier of high-quality Sodium p-Styrenesulfonate (SSS), also known as Sodium 4-Styrenesulfonate. Identified by its CAS number 2695-37-6, SSS is a highly versatile and reactive anionic polymerizable monomer. This crystalline solid is characterized by its styrene backbone combined with a strong sulfonic acid group, providing excellent water solubility and anionic charge density to the resulting polymers. It is an indispensable building block for a wide range of specialty polymers, enhancing properties such as dispersancy, flocculation, water solubility, and ion-exchange capabilities. SSS is crucial in the manufacturing of high-performance superplasticizers for concrete, advanced water treatment polymers, and ion-exchange resins. Aure Chemical is committed to providing Sodium p-Styrenesulfonate that meets stringent purity and performance requirements, ensuring consistency and reliability for your most demanding polymerization processes. Partner with us for a trustworthy supply of this critical monomer.

Basic Information of Sodium p-Styrenesulfonate

Sodium p-Styrenesulfonate (SSS, CAS No. 2695-37-6) is meticulously produced and rigorously tested to meet stringent quality standards. We offer various grades to suit your specific application requirements:

| CAS No.: | 2695-37-6 |

|---|

| EC No.: | 220-266-3 |

|---|

| Linear Formula: | C₈H₇SO₃Na |

|---|

| Molecular Weight: | 206.19 |

|---|

| Appearance: | White to off-white crystalline solid or powder. |

|---|

| Key Properties: | High reactivity in free radical polymerization. Excellent water solubility due to the sulfonate group. Imparts strong anionic charge to copolymers. Good thermal stability of resulting polymers. Broad pH stability.

|

|---|

| Melting Point: | |

|---|

| Boiling Point: | 111-112 °C |

|---|

| Density: | 1.043 g/mL at 25 °C |

|---|

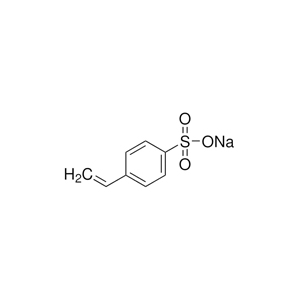

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity SSS ensures a reliable and efficient component for your polymerization reactions, offering consistent quality for diverse industrial applications.

Primary Applications of Sodium p-Styrenesulfonate (SSS)

SSS's unique combination of a polymerizable double bond and a sulfonate group makes it an invaluable monomer in the synthesis of high-performance polymers for various industries:

Concrete Superplasticizers:

A crucial monomer in the production of polycarboxylate ether (PCE) superplasticizers for concrete. SSS-containing polymers enhance concrete workability, reduce water content, and improve strength and durability by acting as powerful dispersants for cement particles.

Dispersants and Suspending Agents:

Polymers containing SSS are highly effective dispersants for various pigments, dyes, and inorganic particles. They are used in textile printing, paints, ceramics, and drilling fluids to prevent agglomeration and ensure uniform dispersion.

Water Treatment Polymers:

Used in the synthesis of water treatment polymers, including flocculants and scale inhibitors. Its anionic charge helps in removing suspended solids from water and preventing the buildup of mineral scale in cooling towers and boilers.

Ion-Exchange Resins:

SSS is a key component in the production of ion-exchange resins, particularly strong acid cation-exchange resins. These resins are critical for water purification, demineralization, and chemical separation processes.

Textile Sizing and Dyeing Aids:

In the textile industry, SSS-based polymers are utilized as sizing agents to improve yarn strength and as dyeing aids to enhance dye uptake and color fastness.

Specialty Emulsifiers and Flocculants:

Its ability to stabilize emulsions and promote flocculation makes it useful in various industrial processes, including emulsion polymerization and wastewater treatment.

Why Choose Aure Chemical for Your Sodium p-Styrenesulfonate (SSS) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your SSS requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Sodium p-Styrenesulfonate is manufactured to stringent purity specifications, ensuring optimal polymerization performance and reliable properties in your finished specialty polymers and additives.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this critical monomer to your facilities worldwide, with flexible packaging options to meet your specific needs.

Expert Technical Support: Our dedicated team of specialists is readily available to offer comprehensive guidance on product application, polymerization conditions, and compatibility with other monomers and additives, helping you optimize your synthesis processes.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and sustainable sourcing practices.

Customized Solutions: We understand that specific applications may require unique specifications. We are open to discussing customized grades and solutions to meet your exact formulation and polymerization requirements.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Sodium p-Styrenesulfonate (SSS). We're ready to empower your innovation in specialty polymers and advanced materials with an unwavering commitment to quality and service.