Discover Aure Chemical's Premium Sodium Bis(trifluoromethanesulfonyl)imide (NaTFSI, CAS 91742-21-1) Supply

Aure Chemical is a premier global supplier of high-quality Sodium Bis(trifluoromethanesulfonyl)imide, widely recognized by its abbreviation NaTFSI. Identified by its CAS number 91742-21-1, NaTFSI is a white crystalline solid that stands out as an advanced sodium salt with exceptional properties. It offers a unique combination of high thermal stability, excellent electrochemical stability, and good ionic conductivity, making it an indispensable component in cutting-edge energy storage systems. NaTFSI is increasingly utilized as a superior electrolyte salt in emerging sodium-ion batteries (NIBs), which are gaining prominence as a cost-effective and abundant alternative to lithium-ion technologies. Furthermore, its versatile properties extend to applications as a phase transfer catalyst and a component in specialized ionic liquids for various electrochemical and synthetic processes. Aure Chemical is committed to providing NaTFSI that meets stringent purity and performance requirements, ensuring consistent and reliable results for your most demanding industrial and research applications. Partner with us for a dependable supply of this critical chemical.

Basic Information of Bis(trifluoromethanesulfonyl)imide

Sodium Bis(trifluoromethanesulfonyl)imide (NaTFSI, CAS No. 91742-21-1) is meticulously produced and rigorously tested to meet stringent quality standards. We offer various grades, including battery grade, to suit your specific application requirements:

| CAS No.: | 91742-21-1 |

|---|

| EC No.: | 804-361-2 |

|---|

| Linear Formula: | NaN(SO₂CF₃)₂ |

|---|

| Molecular Weight: | 303.10 |

|---|

| Appearance: | White crystalline powder. |

|---|

| Melting Point: | 258-261 °C |

|---|

| Solubility: | Highly soluble in water and various polar organic solvents (e.g., acetonitrile, carbonates, alcohols, ionic liquids). |

|---|

| Stability: | Excellent thermal stability (up to ~360°C); superior electrochemical stability; non-hygroscopic. |

|---|

| Purity: | Available in high purity grades (e.g., >99.5%, battery grade) for demanding energy storage applications. |

|---|

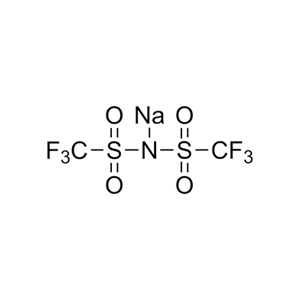

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity NaTFSI ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse energy storage, synthetic, and material science applications.

Primary Applications of Sodium Bis(trifluoromethanesulfonyl)imide (NaTFSI)

NaTFSI's superior properties, including its high ionic conductivity, exceptional thermal and electrochemical stability, and non-corrosive nature, make it a leading choice for a range of advanced technological applications:

Electrolyte Salt in Sodium-Ion Batteries (NIBs):

NaTFSI is a pivotal electrolyte salt for the development of next-generation sodium-ion batteries. Its advantages include:

High Ionic Conductivity: Facilitates efficient sodium ion transport, crucial for NIB performance.

Enhanced Thermal & Electrochemical Stability: Contributes to safer and more durable battery systems compared to some alternatives.

Cost-Effectiveness & Abundance: Sodium is more abundant and less expensive than lithium, making NaTFSI a key enabler for sustainable energy storage.

Solid-State Batteries: Used in the development of solid polymer electrolytes (SPEs) and ceramic electrolytes for all-solid-state sodium-ion batteries.

Ionic Liquid Component:

The bis(trifluoromethanesulfonyl)imide anion ([(CF₃SO₂)₂N]⁻) is a vital component in the synthesis and formulation of ionic liquids. NaTFSI is used to create sodium-based ionic liquids with excellent electrochemical properties, finding applications in:

Electrolytes: For specialized electrochemical cells and supercapacitors.

Solvents: In catalysis, separations, and electrodeposition.

Phase Transfer Catalyst:

NaTFSI can act as an effective phase transfer catalyst in various organic synthesis reactions, facilitating reactions between reactants in immiscible phases by transferring ionic species across the phase boundary.

Additive in Polymer Electrolytes:

It is incorporated into polymer matrices to create flexible and stable ion-conducting polymer electrolytes for various applications, including flexible electronics and sensors.

Electroplating and Electropolymerization:

Due to its high solubility and stability in diverse solvents, it can be used in formulations for electroplating and electropolymerization processes.

Its application as an electrolyte salt is discussed in

TFSI and triflate salts in electrochemistry.

To understand how sodium TFSI fits within the broader triflate and TFSI salt system,

refer to the

overview of triflic acid and triflate chemistry.

Why Choose Aure Chemical for Your NaTFSI Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your NaTFSI requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Sodium Bis(trifluoromethanesulfonyl)imide is manufactured to stringent purity specifications, including advanced battery-grade quality, crucial for achieving optimal and reproducible performance in sensitive electrochemical devices and cutting-edge research.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this essential electrolyte salt to your facilities worldwide, with specialized packaging and handling expertise.

Expert Technical Support: Our dedicated team of specialists is readily available to offer comprehensive guidance on product application, safe handling, optimal storage, and usage in your specific energy storage or chemical processes, ensuring maximum efficiency and safety.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and sustainable sourcing practices.

Customized Solutions: We understand that different applications may require specific purity levels or particle sizes. We are open to discussing customized solutions to meet your exact requirements.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Sodium Bis(trifluoromethanesulfonyl)imide (NaTFSI). We're ready to empower your innovations in energy storage, advanced materials, and electrochemical research with an unwavering commitment to quality and excellence.