Aure Chemical: Your Trusted Source for High-Quality Sodium Alpha Olefin Sulfonate

Aure Chemical is a premier global supplier of high-quality Sodium Alpha Olefin Sulfonate (AOS), identified by its common CAS number 68439-57-6. AOS is a highly effective anionic surfactant derived from natural or synthetic alpha olefins, typically a mixture of sulfonate salts with varying carbon chain lengths, most commonly C14-16. Renowned for its excellent foaming properties, superior detergency, and exceptional stability in hard water and a wide pH range, AOS is a versatile ingredient that delivers outstanding performance across numerous applications. It’s widely utilized in household and industrial cleaning products, personal care formulations, and specialized industrial processes. Aure Chemical is committed to providing Sodium Alpha Olefin Sulfonate that meets rigorous quality standards, ensuring consistency and reliability for your product formulations. Our dedication to safety, quality, and customer satisfaction makes us the ideal partner for your surfactant needs.

Basic Information of Sodium Alpha Olefin Sulfonate

Sodium Alpha Olefin Sulfonate (AOS, CAS No. 68439-57-6) is meticulously produced and rigorously tested to meet stringent quality and performance criteria. We offer various grades to suit your specific application requirements::

| CAS No.: | 68439-57-6 (for Sodium C14-16 Olefin Sulfonate, common blend) |

|---|

| Appearance: | Typically available as a clear to pale yellow liquid or a white to off-white powder/flake. |

|---|

| Key Properties: | Excellent foaming and foam stability, even in hard water. Superior detergency and emulsification capabilities. Good wetting and cleaning performance. Biodegradable. Stable over a broad pH range. Good compatibility with other surfactants. Mildness profile, making it suitable for skin and hair care.

|

|---|

| Density: | 1.054g/cm3 at 20℃ |

|---|

| Concentration: | Available in various active matter concentrations (e.g., 38%, 92%) to meet diverse formulation needs. |

|---|

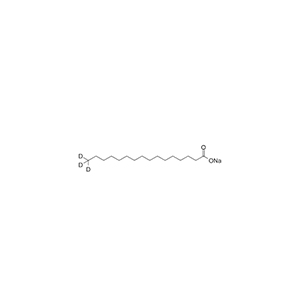

| Chemical Structure: |  |

|---|

Our commitment to delivering high-quality AOS ensures a reliable and efficient component for your product formulations, offering consistent performance for diverse industrial and consumer needs.

Primary Applications of Sodium Alpha Olefin Sulfonate (AOS)

AOS's versatile surfactant properties make it an invaluable ingredient across a broad spectrum of industries:

Personal Care Products:

Widely used in shampoos, body washes, liquid soaps, and facial cleansers due to its excellent foaming, lathering, and cleansing properties, coupled with a good mildness profile compared to some other anionic surfactants. It helps create a rich, stable foam and effectively removes dirt and oil.

Household & Laundry Detergents:

A primary component in laundry detergents (powders and liquids), dishwashing liquids, and all-purpose household cleaners. Its strong detergency and hard water tolerance ensure effective cleaning in various water conditions, preventing soap scum formation.

Industrial & Institutional Cleaners:

Used in formulations for heavy-duty industrial degreasers, floor cleaners, and vehicle wash products where powerful cleaning action and stable foam are required.

Fire-Fighting Foams:

A key ingredient in Aqueous Film-Forming Foam (AFFF) and other fire-fighting foam concentrates due to its high foaming ability and stability, which helps in suppressing fires by forming a stable blanket over flammable liquids.

Textile & Leather Processing:

Employed as a wetting agent, scouring agent, and dyeing auxiliary in the textile and leather industries to improve processing efficiency and product quality.

Construction Industry:

Can be used as an air-entraining agent in concrete and mortar formulations to improve workability and freeze-thaw resistance.

Why Choose Aure Chemical for Your Sodium Alpha Olefin Sulfonate (AOS) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your AOS requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our AOS is manufactured to stringent purity specifications, ensuring optimal performance and stability in your final product formulations, whether for personal care, detergents, or industrial applications.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this essential surfactant to your facilities worldwide, with flexible packaging options to meet your needs.

Expert Technical Support: Our dedicated team of specialists is readily available to offer comprehensive guidance on product application, formulation best practices, and compatibility with other ingredients, helping you optimize your processes.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and sustainable sourcing practices.

Tailored Solutions: We understand that different applications require specific grades. We offer various concentrations and forms of AOS to best fit your unique formulation challenges.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Sodium Alpha Olefin Sulfonate (AOS). We're ready to empower your product innovation and market success with an unwavering commitment to quality and service.