Aure Chemical Delivers Excellence in High-Purity Sodium Lauryl Sulfate

Aure Chemical is a premier global supplier of high-quality Sodium Lauryl Sulfate (SLS), also widely recognized as Sodium Dodecyl Sulfate (SDS). Identified by its CAS number 151-21-3, SLS is a highly effective anionic surfactant commonly available as a white to off-white powder, granules, or liquid solution. It's renowned for its exceptional foaming, wetting, and emulsifying properties, making it a staple ingredient across a vast array of consumer and industrial products. From personal care items like shampoos and toothpastes to powerful household and industrial cleaning agents, SLS consistently delivers strong cleansing performance. Aure Chemical is committed to providing Sodium Lauryl Sulfate that meets rigorous quality and purity standards, ensuring optimal performance and consistency in your formulations. Our dedication to safety, quality, and customer satisfaction makes us the ideal partner for your surfactant needs.

Basic Information of Sodium Lauryl Sulfate

Sodium Lauryl Sulfate (SLS, CAS No. 151-21-3) is meticulously produced and rigorously tested to meet stringent quality and performance criteria. We offer various grades and concentrations to suit your specific application requirements:

| CAS No.: | 151-21-3 |

|---|

| EC No.: | 205-788-1 |

|---|

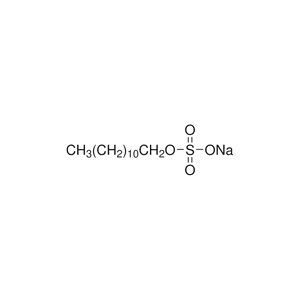

| Linear Formula: | C₁₂H₂₅OSO₃Na |

|---|

| Molecular Weight: | 289.39 |

|---|

| Appearance: | White to off-white powder, granules, or clear to yellowish liquid solution. |

|---|

| Melting Point: | 204-207 °C (lit.) |

|---|

| Boiling Point: | Available in various active matter concentrations (e.g., typically 28%, 30% solution, or >90% powder/needles) to meet diverse formulation needs. |

|---|

| Density: | 1.03 g/mL at 20 °C |

|---|

| Flash Point: | >100°C |

|---|

| Key Properties: | Excellent foaming and lathering capabilities. Strong detergency and cleansing power. Effective wetting and emulsifying agent. Good solubility in water. Biodegradable.

|

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity SLS ensures a reliable and efficient component for your product formulations, offering consistent quality for diverse industrial and consumer needs.

Primary Applications of Sodium Lauryl Sulfate (SLS)

SLS's powerful surfactant properties make it an indispensable ingredient across a broad spectrum of consumer and industrial applications:

Personal Care Products:

Widely used as a primary surfactant in shampoos, conditioners, toothpastes, facial cleansers, body washes, and liquid hand soaps. It's valued for creating rich, abundant lather and effectively removing dirt and oils from skin and hair. In toothpastes, it helps disperse ingredients and create foam for cleaning.

Household & Laundry Detergents:

A significant component in formulations for laundry detergents (powders and liquids), automatic dishwashing detergents, dishwashing liquids, and all-purpose household cleaners. Its strong detergency and foaming power ensure effective cleaning of fabrics, dishes, and surfaces.

Industrial & Institutional Cleaners:

Used in formulations for heavy-duty industrial degreasers, floor cleaners, car wash products, and other specialized cleaning solutions where powerful degreasing and cleaning action are required.

Emulsifier and Wetting Agent:

Acts as an effective emulsifier in various formulations, helping to mix oil and water-based components, and as a wetting agent to improve the spreading of liquids on surfaces.

Laboratory and Research Applications:

In biochemistry and molecular biology, Sodium Dodecyl Sulfate (SDS) is a common component in SDS-PAGE (Polyacrylamide Gel Electrophoresis) for denaturing proteins, and in various cell lysis buffers.

Other Industrial Applications:

Found in some textile processing aids, emulsifiable concentrates for agrochemicals, and as a dispersant in certain industrial processes.

Why Choose Aure Chemical for Your Sodium Lauryl Sulfate (SLS) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your SLS requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Sodium Lauryl Sulfate is manufactured to stringent purity specifications, ensuring optimal performance, consistent foaming, and reliable detergency in your final product formulations, whether for personal care, household, or industrial applications.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this essential surfactant to your facilities worldwide, with flexible packaging options to meet your specific needs.

Expert Technical Support: Our dedicated team of specialists is readily available to offer comprehensive guidance on product application, formulation best practices, and compatibility with other ingredients, helping you optimize your processes and achieve desired product characteristics.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and sustainable sourcing practices.

Customized Solutions: We understand that different applications require specific grades and concentrations. We strive to offer tailored solutions to best fit your unique formulation challenges.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Sodium Lauryl Sulfate (SLS). We're ready to empower your product innovation and market success with an unwavering commitment to quality and service.