Aure Chemical Delivers Excellence in High-Purity Methyl Chloroacetate (CAS 96-34-4)

Aure Chemical is a leading global supplier of Methyl Chloroacetate (MCA), systematically known as Methyl 2-chloroacetate. This highly reactive and versatile chlorinated ester is an indispensable building block in organic synthesis, playing a critical role in the production of a vast array of high-value chemical products. Its unique combination of a reactive chlorine atom and an ester group makes it a key intermediate for introducing specific functionalities into complex molecules across the pharmaceutical, agrochemical, and specialty chemical industries.

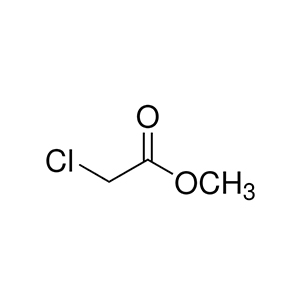

Basic Information of Methyl Chloroacetate

Methyl Chloroacetate (CAS No. 96-34-4) is meticulously manufactured to meet stringent quality standards, ensuring exceptional purity and consistent performance for your demanding applications:

| CAS No.: | 96-34-4 |

|---|

| EC No.: | 202-501-1 |

|---|

| Linear Formula: | ClCH₂COOCH₃ |

|---|

| Molecular Weight: | 108.52 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Pungent, irritating odor. |

|---|

| Melting Point: | -33 °C |

|---|

| Boiling point: | 130 °C740 mm Hg(lit.) |

|---|

| Density: | 1.238 g/mL at 25 °C(lit.) |

|---|

| Solubility: | Slightly soluble in water (hydrolyzes slowly); miscible with most organic solvents like ethanol, ether, benzene. |

|---|

| Flash Point: | 125 °F |

|---|

| Purity: | Corrosive, flammable, highly reactive. |

|---|

| RIDADR: | UN 2295 6.1,3/PG 1 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Methyl Chloroacetate ensures a reliable and efficient component for your complex chemical syntheses.

Primary Applications of Methyl Chloroacetate (MCA)

Methyl Chloroacetate's unique chemical reactivity, stemming from its activated methylene group and electrophilic ester, enables its use in diverse and specialized applications:

Pharmaceutical Synthesis:

MCA is a vital intermediate in the production of numerous active pharmaceutical ingredients (APIs). It's used to introduce specific functional groups or build complex molecular structures, crucial for the synthesis of various drugs and drug precursors.

Agrochemical Manufacturing:

It serves as a key building block for the creation of various agrochemicals, including herbicides, insecticides, and fungicides. Its derivatives contribute to the efficacy and specificity of these crop protection agents.

Dyes and Pigments:

Methyl Chloroacetate is utilized in the synthesis of specific types of dyes and pigments, particularly those requiring precise color control and stability for textile, plastic, and coating applications.

Specialty Chemicals & Polymers:

It's a versatile intermediate for manufacturing a wide range of specialty chemicals, including monomers, polymers, and other fine chemicals. Its reactivity allows for various derivatization reactions to produce tailored materials.

Flavors and Fragrances:

In some instances, MCA derivatives contribute to the synthesis of certain flavor and fragrance compounds, albeit in highly controlled and specific processes.

Why Choose Aure Chemical for Your Methyl Chloroacetate Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Methyl Chloroacetate requirements, you benefit from:

Exceptional Purity & Consistency: Our Methyl Chloroacetate is manufactured to exacting purity standards, critical for the sensitive synthesis processes where it's employed.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling, and optimal storage conditions for Methyl Chloroacetate.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Methyl Chloroacetate. We are ready to support your most complex chemical endeavors.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Acute Toxicity (GHS06), Corrosive (GHS05), Irritant (GHS07)

Hazard Statements: Flammable liquid and vapor; toxic if swallowed, in contact with skin, or if inhaled; causes severe skin burns and eye damage; may cause respiratory irritation.

UN Number: UN 2295

Hazard Class: 6.1 (Toxic Substances), 3 (Flammable Liquids)

Packing Group: I

GHS02: Flammable

GHS02: Flammable GHS06: Acute Toxicity

GHS06: Acute Toxicity GHS05: Corrosive

GHS05: Corrosive GHS07: Irritant

GHS07: Irritant