Premium Diethyl Carbonate (CAS 105-58-8)by Aure Chemical

Aure Chemical is a leading global supplier of Diethyl Carbonate (DEC), also systematically known as Carbonic acid, diethyl ester. This versatile organic compound is highly valued as a critical component in advanced technologies and sustainable industrial processes. Recognized as a "green" chemical, DEC offers a unique blend of properties as an excellent solvent and a reactive intermediate. Our high-purity Diethyl Carbonate is indispensable across industries ranging from cutting-edge lithium-ion battery manufacturing to pharmaceuticals, paints, and coatings.

Basic Information of Diethyl Carbonate

Diethyl Carbonate (CAS No. 105-58-8) is meticulously produced to meet stringent quality and environmental standards, ensuring exceptional purity and consistent performance for your demanding applications:

| CAS No.: | 105-58-8 |

|---|

| EC No.: | 203-311-1 |

|---|

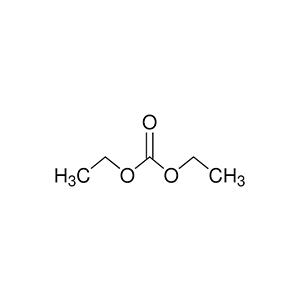

| Linear Formula: | (CH₃CH₂O)₂CO |

|---|

| Molecular Weight: | 118.13 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Mild, pleasant, ethereal odor. |

|---|

| Melting Point: | -43 °C (lit.) |

|---|

| Boiling point: | 126-128 °C (lit.) |

|---|

| Density: | 0.975 g/mL at 25 °C (lit.) |

|---|

| Solubility: | Slightly soluble in water; miscible with many organic solvents, including alcohols, ketones, and esters |

|---|

| Flash Point: | 88 °F |

|---|

| Purity: | Flammable liquid and vapor; relatively low toxicity. |

|---|

| RIDADR: | UN 2366 3/PG 3 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Diethyl Carbonate ensures a reliable and efficient component for your innovative manufacturing and formulation needs.

Primary Applications of Diethyl Carbonate (DEC)

Diethyl Carbonate's distinctive properties, including its high boiling point, low viscosity, and excellent electrochemical stability, make it a crucial chemical for a wide range of advanced and sustainable applications:

Lithium-Ion Battery Electrolytes:

DEC is a vital solvent component in the electrolyte solutions for lithium-ion batteries. Its low viscosity, wide liquid range, and good electrochemical properties contribute significantly to the battery's performance, safety, and cycle life, powering electric vehicles and portable electronic devices.

Green Solvent:

As an environmentally friendly and relatively non-toxic solvent, DEC is increasingly adopted as a safer alternative to conventional hazardous solvents like ketones and aromatic hydrocarbons. It's used in formulations for paints, coatings, adhesives, and as a cleaning agent in various industrial processes.

Pharmaceutical Synthesis:

DEC serves as a valuable solvent and a reactive intermediate in the synthesis and purification of various active pharmaceutical ingredients (APIs) and other fine chemicals, where its low toxicity and specific reactivity are beneficial.

Chemical Intermediate & Carbonylation Reagent:

It acts as a versatile chemical intermediate, particularly in transesterification reactions, and as a carbonylation reagent, offering a safer alternative to phosgene in certain synthetic pathways. It is used in the production of other carbonates and specialty chemicals.

Plasticizers and Polymer Additives:

In some niche applications, DEC or its derivatives can be incorporated as plasticizers or additives for polymers, imparting desired flexibility and processing characteristics.

Why Choose Aure Chemical for Your Diethyl Carbonate Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Diethyl Carbonate requirements, you benefit from:

Exceptional Purity & Consistency: Our Diethyl Carbonate is manufactured to stringent purity specifications, critical for sensitive applications like battery electrolytes, ensuring optimal performance and reliability.

Sustainable Sourcing: We prioritize environmentally responsible production methods and supply chains, aligning with the "green" profile of DEC.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling, and optimal storage conditions for Diethyl Carbonate.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Diethyl Carbonate. We are ready to support your most innovative and sustainable chemical endeavors.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Exclamation Mark (GHS07)

Hazard Statements: Flammable liquid and vapor; causes skin and eye irritation; may cause drowsiness or dizziness.

UN Number: UN 2366

Hazard Class: 3 (Flammable Liquids)

Packing Group: III

GHS02: Flammable

GHS02: Flammable GHS07: Exclamation mark

GHS07: Exclamation mark