High-Purity Dimethyl Carbonate (CAS 616-38-6) from Aure Chemical – Your Trusted Source

Aure Chemical is a leading global supplier of Dimethyl Carbonate (DMC), also commonly known as Methyl Carbonate. Recognized as a prominent "green" chemical, DMC is a highly versatile and environmentally friendly compound that combines the properties of a solvent, a reagent, and a methylating agent. Our high-purity Dimethyl Carbonate is increasingly vital across diverse industries, from advanced battery technology and pharmaceuticals to paints, coatings, and polymer synthesis.

Basic Information of Dimethyl Carbonate

Dimethyl Carbonate (CAS No. 616-38-6) is meticulously produced to meet stringent quality and environmental standards, ensuring exceptional purity and consistent performance for your demanding applications:

| CAS No.: | 616-38-6 |

|---|

| EC No.: | 210-478-4 |

|---|

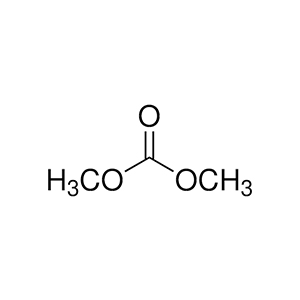

| Linear Formula: | (CH₃O)₂CO |

|---|

| Molecular Weight: | 90.08 |

|---|

| Appearance: | Clear, colorless liquid. |

|---|

| Odor: | Mild, sweet, ester-like odor. |

|---|

| Melting Point: | 2-4 °C (lit.) |

|---|

| Boiling point: | 90 °C (lit.) |

|---|

| Density: | 1.069 g/mL at 25 °C (lit.) |

|---|

| Solubility: | Slightly soluble in water; miscible with most organic solvents, including alcohols, ketones, and esters. |

|---|

| Flash Point: | 65 °F |

|---|

| Purity: | Flammable liquid and vapor; low toxicity compared to traditional solvents. |

|---|

| RIDADR: | UN 1161 3/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Dimethyl Carbonate ensures a reliable and sustainable component for your innovative manufacturing and formulation needs.

Primary Applications of Dimethyl Carbonate (DMC)

Dimethyl Carbonate's unique combination of properties, including its low toxicity, excellent solvency, and reactive methylating capability, makes it a highly valuable chemical for a wide range of cutting-edge applications:

Lithium-Ion Battery Electrolytes:

DMC is a critical component in the electrolyte solutions for lithium-ion batteries. Its low viscosity, high dielectric constant, and good electrochemical stability contribute to efficient ion transport and overall battery performance, powering electric vehicles and portable electronics.

Polycarbonate Synthesis:

It serves as a safer, phosgene-free raw material for the synthesis of polycarbonates, widely used engineering plastics known for their high strength, stiffness, and impact resistance in applications like optical media, automotive parts, and electronic housings.

Green Solvent:

As an environmentally friendly and non-toxic solvent, DMC is increasingly replacing hazardous solvents like methyl ethyl ketone (MEK), toluene, and xylene in various applications. It's used in paints, coatings, adhesives, printing inks, and as a cleaning agent.

Methylating Agent:

DMC acts as a mild and selective methylating agent, offering a safer alternative to conventional methylating reagents like methyl halides or dimethyl sulfate. It's employed in the synthesis of various organic compounds, including pharmaceuticals, agrochemicals, and fine chemicals.

Pharmaceutical Manufacturing:

Its role as a green solvent and a reactive intermediate makes DMC valuable in the synthesis and purification processes of active pharmaceutical ingredients (APIs) and other pharmaceutical compounds.

Catalyst and Reagent:

DMC can also function as a catalyst or reagent in various chemical reactions, including transesterification and carbonylation, facilitating the production of other valuable chemicals.

Why Choose Aure Chemical for Your Dimethyl Carbonate Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Dimethyl Carbonate requirements, you benefit from:

Exceptional Purity & Consistency: Our Dimethyl Carbonate is manufactured to stringent purity specifications, ensuring optimal performance for sensitive applications like battery electrolytes and pharmaceutical synthesis.

Sustainable Sourcing: We prioritize environmentally responsible production methods and supply chains, aligning with the "green" nature of DMC itself.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling, and optimal storage conditions for Dimethyl Carbonate.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Dimethyl Carbonate. We are ready to support your most innovative and sustainable chemical endeavors.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Irritant (GHS07)

Hazard Statements: Highly flammable liquid and vapor; may cause skin irritation; may cause serious eye irritation.

UN Number: UN 1161

Hazard Class: 3 (Flammable Liquids)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS07: Irritant

GHS07: Irritant