Aure Chemical: Your Premier Source for Stable, High-Purity Methyl Methacrylate (CAS 80-62-6)

Aure Chemical is a leading global supplier of Methyl Methacrylate (MMA), commonly known as Methyl 2-methylprop-2-enoate. This versatile and highly sought-after acrylic monomer is the fundamental building block for a vast array of high-performance plastics, resins, and specialty chemicals. Our commitment to quality ensures a precisely manufactured, stabilized MMA product, crucial for reliable polymerization and the consistent production of superior end materials.

Basic Information of Methyl Methacrylate

Methyl Methacrylate (CAS No. 80-62-6) is meticulously produced to meet stringent purity and stability standards, ensuring optimal performance for your most demanding applications:

| CAS No.: | 80-62-6 |

|---|

| EC No.: | 201-297-1 |

|---|

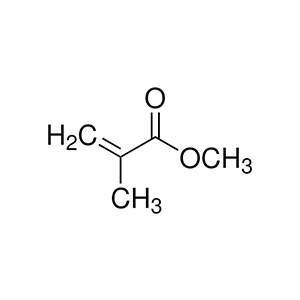

| Linear Formula: | CH₂=C(CH₃)COOCH₃ |

|---|

| Molecular Weight: | 100.12 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Pungent, fruity odor. |

|---|

| Melting Point: | -48 °C (lit.) |

|---|

| Boiling point: | 100 °C (lit.) |

|---|

| Density: | 0.936 g/mL at 25 °C (lit.) |

|---|

| Solubility: | Slightly soluble in water; miscible with most organic solvents. |

|---|

| Flash Point: | 50 °F |

|---|

| Purity: | Flammable liquid and vapor; reactive monomer. |

|---|

| RIDADR: | UN 1247 3/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Ensuring Stability: Our Commitment to Reliable MMA Supply

Methyl Methacrylate is a highly reactive monomer that can undergo self-polymerization if not handled and stored correctly. At Aure Chemical, we ensure the stability of our MMA through:

Careful Inhibition: Our MMA is consistently supplied with the appropriate concentration of polymerization inhibitors (e.g., MEHQ) to effectively prevent premature polymerization during storage and transport.

Oxygen Management: We understand that the effectiveness of many inhibitors relies on the presence of oxygen. Our packaging and storage recommendations ensure adequate oxygen levels are maintained to activate the inhibitor's protective action.

Strict Quality Control: Each batch undergoes rigorous quality checks to confirm inhibitor levels and ensure the product remains stable under recommended storage conditions, giving you peace of mind.

Safe Handling Guidelines: We provide clear guidelines for optimal storage (cool, dark, well-ventilated areas, away from heat and ignition sources) and handling to maintain product integrity and safety until use.

This commitment to stability ensures you receive a high-quality, ready-to-use monomer that performs consistently in your processes.

Primary Applications of Methyl Methacrylate (MMA)

MMA's exceptional properties, particularly its ability to polymerize into highly clear, durable, and weather-resistant materials, drive its widespread use:

Polymethyl Methacrylate (PMMA / Acrylic Glass):

MMA is the primary monomer for producing PMMA, commonly known as acrylic glass or Plexiglas. PMMA is valued for its superior optical clarity, light weight, shatter resistance, and weatherability, used in windows, signage, automotive components (e.g., taillights), LCD screens, and optical lenses.

Paints, Coatings, and Inks:

Acrylic resins derived from MMA are widely used in high-performance coatings for automotive finishes, architectural paints, and industrial coatings due to their excellent gloss retention, hardness, and resistance to UV light and chemicals.

Adhesives and Sealants:

MMA-based formulations are key ingredients in structural adhesives, dental adhesives, and sealants, offering strong bonding, fast curing times, and durability in various demanding applications.

Dental and Medical Materials:

Its biocompatibility and durability make MMA a critical component in dental restorative materials (fillings, dentures), bone cements, and other medical devices and implants.

Building and Construction:

MMA-based materials are used in flooring compounds, road markings, and decorative panels due to their wear resistance, chemical resistance, and ability to form strong bonds with concrete and other substrates.

Specialty Chemicals & Polymers:

It also serves as a monomer in the production of various copolymers and specialty chemicals designed for specific functionalities, such as thickeners, dispersants, and impact modifiers.

Why Choose Aure Chemical for Your Methyl Methacrylate (MMA) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your MMA requirements, you benefit from:

Guaranteed Purity & Stability: Our Methyl Methacrylate is manufactured to the highest purity standards and precisely stabilized to ensure reliable performance in your polymerization processes.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential monomer to your facilities worldwide.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling, and optimal storage conditions for MMA.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Methyl Methacrylate. We are ready to support your most innovative and demanding material science endeavors.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Irritant (GHS07), Health Hazard (GHS08)

Hazard Statements: Highly flammable liquid and vapor; causes skin irritation; causes serious eye irritation; may cause respiratory irritation; may cause an allergic skin reaction.

UN Number: UN 1247

Hazard Class: 3 (Flammable Liquids)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS07: Irritant

GHS07: Irritant GHS08: Health Hazard

GHS08: Health Hazard