Aure Chemical: Reliable Supplier of High-Purity Ethylidene Chloride (CAS 75-34-3)

Aure Chemical is a premier global supplier of high-quality Ethylidene Chloride, commonly known by its systematic name 1,1-Dichloroethane (1,1-DCA). This clear, colorless liquid is a versatile chlorinated hydrocarbon, highly valued for its excellent solvency and its role as a key chemical intermediate. Our high-purity Ethylidene Chloride is an essential component in a broad spectrum of industries, finding widespread use as a solvent in various industrial processes, an effective extraction agent, and a crucial building block in complex organic syntheses.

Basic Information of Ethylidene Chloride

Ethylidene Chloride (CAS No. 75-34-3) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your most demanding applications:

| CAS No.: | 75-34-3 |

|---|

| EC No.: | 200-863-5 |

|---|

| Linear Formula: | C₂H₄Cl₂ |

|---|

| Molecular Weight: | 98.96 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Sweet, chloroform-like odor. |

|---|

| Melting point: | 57°C |

|---|

| Boiling point: | 235℃ |

|---|

| Density: | 1.18 g/cm3 |

|---|

| Solubility: | Slightly soluble in water; miscible with most organic solvents (e.g., ethanol, ether, acetone). |

|---|

| Flash point: | -6°C |

|---|

| Nature: | Flammable liquid and vapor, harmful if swallowed or inhaled, irritating to skin and eyes. |

|---|

| RIDADR: | UN 2362 3/PG 2 |

|---|

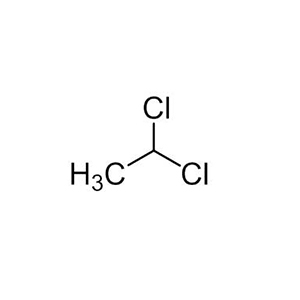

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Ethylidene Chloride ensures a reliable and efficient component for your complex manufacturing and synthesis processes.

Primary Applications of Ethylidene Chloride (1,1-Dichloroethane)

Ethylidene Chloride's properties as a solvent, extraction agent, and reactive intermediate make it an incredibly valuable and versatile chemical with applications across numerous sectors:

Industrial Solvent:

It is widely used as a solvent for fats, waxes, resins, and various organic compounds in industries such as coatings, adhesives, and textile processing.

Extraction Agent:

Due to its excellent solvency and volatility, Ethylidene Chloride serves as an effective extraction agent in chemical processes, for example, in the production of oils and fats.

Chemical Intermediate:

It is a crucial intermediate in organic synthesis, used in the production of other chemicals, including 1,1,1-trichloroethane and vinyl chloride (though less common for vinyl chloride than 1,2-dichloroethane).

Cleaning Agent and Degreaser:

Its ability to dissolve greases and oils makes it useful in some specialized cleaning and degreasing applications for metal parts and equipment.

Laboratory Reagent:

Ethylidene Chloride is also employed in laboratory settings as a solvent for various reactions and analytical procedures.

Why Choose Aure Chemical for Your Ethylidene Chloride Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Ethylidene Chloride requirements, you benefit from:

Exceptional Purity & Consistency: Our Ethylidene Chloride is manufactured to stringent purity specifications, critical for maximizing yields in complex syntheses and ensuring consistent quality in your downstream products.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all strict safety and regulatory standards for hazardous materials.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Ethylidene Chloride.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients handling this versatile material.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Ethylidene Chloride. We're ready to support your most demanding and innovative industrial and chemical manufacturing processes.

FAQ — Ethylidene Chloride (1,1-Dichloroethane) (CAS 75-34-3)

What is Ethylidene Chloride (1,1-Dichloroethane)?

Ethylidene Chloride, also known as 1,1-Dichloroethane, is a chlorinated hydrocarbon

(C2H4Cl2) widely used as a solvent and as an intermediate

in chemical synthesis. It is a clear, volatile liquid with a chloroform-like odor.

What are the main applications of Ethylidene Chloride?

It is mainly used as an intermediate in the production of vinylidene chloride (for polymers and resins),

as a solvent in organic synthesis, and in small-scale applications such as degreasing or extraction processes.

Is Ethylidene Chloride hazardous?

Yes. It is classified as a flammable liquid and may cause irritation to the eyes, skin,

and respiratory tract. Prolonged exposure can affect the central nervous system. Always handle

according to the Safety Data Sheet (SDS) and local regulations.

How should Ethylidene Chloride be stored?

Store in a cool, dry, well-ventilated area away from heat and ignition sources.

Keep containers tightly closed and segregated from strong oxidizers and incompatible materials.

Use explosion-proof equipment where necessary.

What should I do in case of a spill or leak?

Evacuate non-essential personnel, remove ignition sources, and ventilate the area.

Absorb small spills with inert, non-combustible material (e.g., vermiculite, dry sand).

Collect into labeled hazardous-waste containers. Prevent release into drains and waterways.

Refer to the SDS for detailed emergency procedures.

How is Ethylidene Chloride transported?

It is regulated as a hazardous material. Typically assigned UN 2362 (1,1-Dichloroethane),

classified under Class 3 (Flammable liquids). Packaging group and other requirements

depend on transport regulations (ADR, IMDG, IATA). Always verify with the current SDS and applicable transport codes.

Where can I find detailed safety and regulatory information?

The definitive source is the product’s Safety Data Sheet (SDS). It provides legally binding

information on hazards, handling, storage, transport, exposure limits, and emergency measures.

Contact Aure Chemical for the latest SDS and technical documentation.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Acute Toxicity (GHS07), Health Hazard (GHS08)

Hazard Statements: Highly flammable liquid and vapor; harmful if swallowed or inhaled; may cause drowsiness or dizziness; suspected of causing cancer.

UN Number: UN 2362

Hazard Class: 3 (Flammable Liquids)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS07: Acute Toxicity

GHS07: Acute Toxicity GHS08: Health Hazard

GHS08: Health Hazard