Explore Top-Quality Ethylene Dichloride (CAS 107-06-2) with Aure Chemical

Aure Chemical is a premier global supplier of high-quality Ethylene Dichloride (EDC), systematically known as 1,2-Dichloroethane. This clear, colorless liquid is one of the most significant chlorinated hydrocarbons, indispensable as a bulk chemical commodity. Its primary role is as a crucial intermediate in the production of vinyl chloride monomer (VCM), which is the building block for polyvinyl chloride (PVC) plastic. Beyond this, EDC serves as a versatile solvent and a key reactant in numerous other industrial chemical syntheses. Aure Chemical's high-purity Ethylene Dichloride is essential for manufacturing plastics, solvents, and other specialty chemicals worldwide.

Basic Information of Ethylene Dichloride

Ethylene Dichloride (CAS No. 107-06-2) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your most demanding applications:

| CAS No.: | 107-06-2 |

|---|

| EC No.: | 203-458-1 |

|---|

| Linear Formula: | C₂H₄Cl₂ |

|---|

| Molecular Weight: | 98.96 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Sweet, chloroform-like odor. |

|---|

| Melting point: | -35 °C (lit.) |

|---|

| Boiling point: | 83 °C (lit.) |

|---|

| Density: | 1.256 g/mL at 25 °C (lit.) |

|---|

| Solubility: | Slightly soluble in water; miscible with most organic solvents (e.g., ethanol, ether, acetone). |

|---|

| Flash point: | 60 °F |

|---|

| Nature: | Flammable liquid and vapor, harmful if swallowed or inhaled, irritating to skin and eyes, suspected carcinogen. |

|---|

| RIDADR: | UN 1184 3, 6.1/PG 2 |

|---|

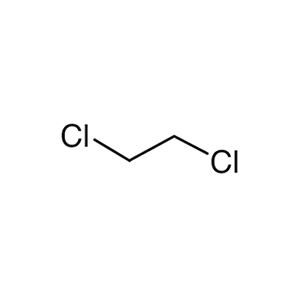

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Ethylene Dichloride ensures a reliable and efficient component for your complex manufacturing and synthesis processes.

Primary Applications of Ethylene Dichloride (1,2-Dichloroethane)

Ethylene Dichloride's high reactivity and solvent properties make it an incredibly valuable and versatile chemical with applications across numerous industries:

Vinyl Chloride Monomer (VCM) Production:

The vast majority (over 90%) of Ethylene Dichloride produced globally is consumed in the manufacture of vinyl chloride monomer (VCM). VCM is then polymerized to produce polyvinyl chloride (PVC), one of the world's most widely used plastics for pipes, window frames, flooring, and many other applications.

Industrial Solvent:

EDC is an excellent solvent for fats, waxes, resins, and various organic compounds. It is used as a solvent in the production of adhesives, coatings, lacquers, and in textile processing.

Chemical Intermediate:

It serves as a crucial intermediate in the synthesis of a wide range of other organic chemicals, including ethylenediamine, perchloroethylene, trichloroethylene, and other chlorinated solvents.

Degreasing and Extraction Agent:

Its strong solvent capabilities make it useful in certain specialized degreasing operations for metal parts and in extraction processes in the chemical and pharmaceutical industries.

Why Choose Aure Chemical for Your Ethylene Dichloride Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Ethylene Dichloride requirements, you benefit from:

Exceptional Purity & Consistency: Our Ethylene Dichloride is manufactured to stringent purity specifications, critical for maximizing yields in complex syntheses and ensuring consistent quality in your downstream products, especially for VCM and PVC production.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all strict safety and regulatory standards for hazardous materials.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Ethylene Dichloride.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients handling this vital material.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Ethylene Dichloride. We're ready to support your most demanding and innovative industrial and chemical manufacturing processes.

Hazards Classification for Ethylene Dichloride (CAS No. 107-06-2)

GHS Classification: Flammable Liquid (GHS02), Acute Toxicity (GHS06), Health Hazard (GHS08)

Hazard Statements: Highly flammable liquid and vapor; toxic if swallowed or inhaled; may cause cancer; causes serious eye irritation; may cause respiratory irritation.

UN Number: UN 1184

Hazard Class: 3 (Flammable Liquids), 6.1 (Toxic Substances)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS06: Acute toxicity

GHS06: Acute toxicity GHS08: Health hazard

GHS08: Health hazard