Aure Chemical Delivers Excellence in High-Purity Boron Trifluoride (BF₃)

Aure Chemical is a trusted global supplier of Boron Trifluoride (BF₃), an indispensable chemical compound renowned for its exceptional properties as a strong Lewis acid. This colorless, pungent gas plays a critical role across a multitude of industrial sectors, from advanced chemical synthesis to cutting-edge electronics and metallurgy. We are dedicated to providing BF₃ that meets the highest standards of purity and reliability, essential for the most demanding applications.

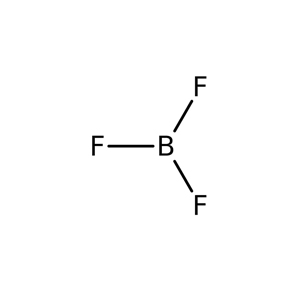

Basic Information of Boron Trifluoride

Boron Trifluoride (CAS No. 7637-07-2) is characterized by its unique physical and chemical attributes:

| CAS No.: | 7637-07-2 |

|---|

| EC No.: | 231-569-5 |

|---|

| Linear Formula: | BF₃ |

|---|

| Molecular Weight: | 67.81 |

|---|

| Appearance: | Colorless gas |

|---|

| Odor: | Pungent |

|---|

Melting point:

| -126.8 ℃ |

|---|

| Boiling point: | -100.3 ℃ |

|---|

| Density: | 0.00276 g/cm³ |

|---|

| Solubility | Decomposes exothermically in water (hydrolyzes). |

|---|

| Nature: | Powerful Lewis acid (electron pair acceptor). |

|---|

| RIDADR: | UN 1008 2.3 |

|---|

| Chemical Structure: |  |

|---|

These properties make BF₃ an incredibly reactive and versatile reagent, indispensable in processes requiring strong acidic catalysis or precise chemical manipulation.

Diverse Applications of Boron Trifluoride

The unique reactivity and catalytic power of Aure Chemical's Boron Trifluoride make it invaluable in a wide array of industrial and technological applications:

Organic Reaction Catalyst: Widely employed as a highly effective catalyst in various organic reactions, including esterification, alkylation, polymerization, isomerization, sulfonation, and nitration.

Antioxidant in Metallurgy: Used as an antioxidant during magnesium casting and alloying processes to prevent oxidation and improve metal quality.

Raw Material for Boron Compounds: Serves as a primary raw material for the preparation of other critical boron compounds, such as boron halides, elemental boron, various boranes, and sodium borohydride.

Condensation & Curing Agent: In numerous organic reactions and petroleum processing, BF₃ and its complexes act as catalysts for condensation reactions. They are also crucial as curing agents or accelerators in epoxy resins.

Semiconductor Manufacturing: In the advanced electronics industry, boron trifluoride and its compounds are predominantly utilized as P-type dopants for semiconductors, as ion beam sources for ion implantation, and as plasma etching gases.

Optical Fiber Manufacturing & Nuclear Technology: Boron trifluoride is used in the manufacturing of optical fibers (e.g., for producing preforms), as a catalyst in general organic synthesis, and as a raw material for synthesizing specialized organic boron compounds. It also finds applications in nuclear technology, particularly in neutron detection.

Agent to Facilitate Casting: Boron trifluoride is also used as a flux or antioxidant to facilitate processes in steel casting, improving material flow and reducing impurities.

Why Partner with Aure Chemical for Your Boron Trifluoride Needs?

Aure Chemical is committed to delivering excellence and reliability in chemical supply. By choosing us for your Boron Trifluoride requirements, you gain access to:

Uncompromised Purity: Our BF₃ undergoes stringent quality control to ensure exceptional purity, critical for sensitive applications in electronics and catalysis.

Secure & Efficient Supply: We maintain a robust and secure supply chain, ensuring safe handling and timely delivery of this reactive gas to meet your operational demands.

Expert Technical Support: Our team of chemical specialists is available to provide comprehensive technical assistance, guiding you on optimal product application and safe handling protocols.

Commitment to Safety: We adhere to the highest safety and environmental standards throughout our processes, from sourcing to distribution.

Experience the Aure Chemical difference with a dependable supply of high-quality Boron Trifluoride. Contact us today to discuss your specific requirements or to request a quote!

Hazards Classification

GHS Classification: Gas Under Pressure (GHS04), Corrosive (GHS05), Acute Toxicity (GHS06)

Hazard Statements: Toxic if inhaled; causes severe skin burns and eye damage; contains gas under pressure, may explode if heated.

UN Number: UN 1008

Hazard Class: 2.3 (Toxic Gases)

Packing Group: Not applicable (compressed gas)

GHS04: Gas under pressure

GHS04: Gas under pressure GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity