Aure Chemical: Your Reliable Partner for High-Quality Boron Trifluoride Tetrahydrofuran Complex (BF₃-THF)

Aure Chemical is a trusted supplier of Boron Trifluoride Tetrahydrofuran Complex (BF₃-THF), a widely recognized and highly effective Lewis acid catalyst. This clear, colorless liquid provides a stable and easily handled source of Boron Trifluoride (BF₃), making it an invaluable reagent for a vast array of organic synthesis applications, from academic research to industrial production.

Basic Information of Boron Trifluoride Tetrahydrofuran Complex

Boron Trifluoride Tetrahydrofuran Complex (CAS No. 462-34-0) is characterized by its significant properties:

| CAS No.: | 462-34-0 |

|---|

| EC No.: | 207-325-9 |

|---|

| Linear Formula: | C₄H₈BF₃O |

|---|

| Molecular Weight: | 139.91 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Melting point: | 11-13 °C (lit.) |

|---|

| Boiling point: | 180 °C (lit.) |

|---|

| Density: | 1.268 g/mL at 25 °C (lit.) |

|---|

| Solubility | Miscible with dimethyl formamide. |

|---|

| Flash Point: | 198°F |

|---|

| Nature: | Strong Lewis acid. |

|---|

| RIDADR: | UN 2924 8/PG 2 |

|---|

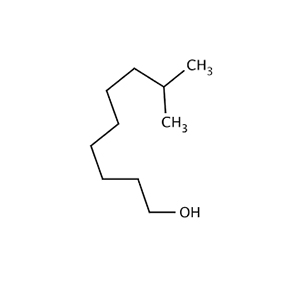

| Chemical Structure: |  |

|---|

Its precise composition and catalytic strength make it an essential tool for chemists requiring efficient and selective Lewis acid catalysis.

Main Functions and Applications of Boron Trifluoride Tetrahydrofuran Complex

The potent Lewis acidity and broad utility of Aure Chemical's Boron Trifluoride Tetrahydrofuran Complex enable its diverse applications across various advanced chemical syntheses:

Catalyst for Organic Reactions: This complex is a cornerstone in organic chemistry, serving as a versatile and efficient Lewis acid catalyst. It promotes a wide range of reactions, including Friedel-Crafts alkylation and acylation, Diels-Alder reactions, aldol reactions, rearrangements, and epoxide openings, making it indispensable for C-C bond formations and complex molecular architectures.

Preparation of Pharmaceutical Products: Due to its high reactivity and selectivity, BF₃-THF is commonly employed as a catalyst in the synthesis of various pharmaceutical products. This includes facilitating key steps in the production of complex drug molecules such as cephalosporins and fluoroquinolones, where precise catalytic control is paramount.

Preparation of Boranes and Targeted Drugs: Beyond its role as a catalyst, BF₃-THF is an important raw material for the synthesis of various boranes (boron-hydrogen compounds) and the development of boron-containing targeted drugs. This includes applications in areas like Boron Neutron Capture Therapy (BNCT) and other novel boron-based therapeutics.

Pharmaceutical Intermediate: In the pharmaceutical field, BF₃-THF is also directly utilized as a crucial pharmaceutical intermediate. Its ability to readily participate in various transformations makes it a valuable building block for synthesizing more complex drug candidates and active pharmaceutical ingredients (APIs).

Why Choose Aure Chemical for Your Boron Trifluoride Tetrahydrofuran Complex Needs?

Aure Chemical is committed to delivering excellence and reliability in chemical supply. When you choose us for your Boron Trifluoride Tetrahydrofuran Complex requirements, you benefit from:

Assured Purity & Performance: Our BF₃-THF undergoes stringent quality control to ensure high purity and consistent catalytic activity, vital for sensitive organic reactions and industrial processes.

Reliable Supply Chain: We maintain a robust and efficient global supply chain, ensuring timely and secure delivery of this valuable reagent.

Technical Expertise: Our knowledgeable team is always available to provide comprehensive support and answer any technical questions you may have regarding product application, handling, and safety.

Commitment to Quality & Safety: We adhere to the highest quality control, safety, and environmental standards throughout our operations, from manufacturing to distribution.

Partner with Aure Chemical for a seamless and dependable supply of high-quality Boron Trifluoride Tetrahydrofuran Complex. We are ready to assist you in finding the perfect solution for your specific application requirements.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Corrosive (GHS05), Acute Toxicity (GHS06)

Hazard Statements: Highly flammable liquid and vapor. Reacts violently with water. Toxic if swallowed, in contact with skin or if inhaled. Causes severe skin burns and eye damage.

UN Number: UN 2924

Hazard Class: 3 (Flammable Liquids), Subsidiary risk 8

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity