Your Boron Trifluoride Diethyl Etherate Complex (BF₃·OEt₂) Partner – Superior Supply from Aure Chemical

Aure Chemical is a premier supplier of Boron Trifluoride Diethyl Etherate Complex (BF₃·OEt₂), a highly versatile and indispensable liquid Lewis acid. Known for its potent catalytic activity and enhanced ease of handling compared to gaseous Boron Trifluoride (BF₃), this complex plays a pivotal role in numerous industrial and scientific applications globally.

Basic Information of Boron Trifluoride Diethyl Etherate

Boron Trifluoride Diethyl Etherate Complex (CAS No. 109-63-7) is characterized by its precise composition and robust properties:

| CAS No.: | 109-63-7 |

|---|

| EC No.: | 203-689-8 |

|---|

| Linear Formula: | C₄H₁₀BF₃O |

|---|

| Molecular Weight: | 141.93 |

|---|

| Appearance: | Colorless to light yellow transparent liquid |

|---|

| Boiling point: | 126-129 °C(lit.) |

|---|

| Density: | 1.15 g/mL(lit.) |

|---|

| Solubility | Miscible with ether and alcohol |

|---|

| Flash Point: | 118 °F |

|---|

| Nature: | Strong Lewis acid, forming a stable complex with diethyl ether, but remains sensitive to moisture. |

|---|

| RIDADR: | UN 2604 8/PG 1 |

|---|

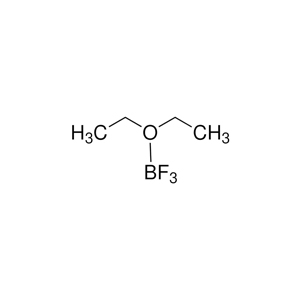

| Chemical Structure: |  |

|---|

Its consistent quality and well-defined reactivity ensure reliable performance in the most demanding chemical processes.

Primary Functions and Applications of Boron Trifluoride Diethyl Etherate Complex

The exceptional catalytic capabilities and unique properties of Aure Chemical's Boron Trifluoride Diethyl Etherate Complex make it indispensable across various high-tech and industrial sectors:

Core Catalyst in Organic Synthesis:

Boron Trifluoride Diethyl Etherate Complex stands as one of the most important and widely utilized Lewis acid catalysts in organic synthesis. It is extensively employed across the pharmaceutical, agrochemical, and fine chemical industries. Its high activity and selectivity ensure exceptional performance in a diverse range of chemical transformations, including:

Its catalytic prowess is crucial for enhancing reaction efficiency, controlling selectivity, and enabling the synthesis of complex molecular structures.

Esterification and Etherification reactions

Alkylation and Acylation (e.g., Friedel-Crafts reactions)

Addition Reactions (e.g., Aldol reactions, Diels-Alder reactions)

Rearrangement Reactions

Catalyst for Synthetic Rubber and Resin Production:

This complex also plays a significant role in the polymer industry, serving as a powerful catalyst for the production of various synthetic rubbers and resins:

It is a highly effective catalyst for the production of Polyformaldehyde (POM), facilitating the cationic polymerization of formaldehyde or its cyclic trimer.

Under specific conditions, it can be employed in the production of certain synthetic rubbers like Butadiene Rubber via cationic polymerization routes.

It is broadly applied in the synthesis of various resins and paints, promoting polymerization and cross-linking reactions to achieve desired polymer structures and properties.

Basic Raw Material for Borane (Boron-Hydrogen Compound) Production:

Boron Trifluoride Diethyl Etherate Complex is a fundamental starting material for the efficient production of borane compounds (boron-hydrogen compounds). Boranes are a class of high-energy-density compounds that have been, and continue to be, investigated for their use in high-energy fuels (like rocket propellants) and as important chemical reducing agents. This complex efficiently generates various boranes through controlled reactions with hydride sources.

Why Choose Aure Chemical for Your Boron Trifluoride Diethyl Etherate Complex?

Aure Chemical is committed to delivering superior chemical solutions and unparalleled customer support. By partnering with us for your Boron Trifluoride Diethyl Etherate Complex requirements, you benefit from:

Guaranteed Purity & Consistent Performance: Our BF₃·OEt₂ undergoes stringent quality control to ensure high purity and reliable catalytic activity, crucial for sensitive organic synthesis and advanced material applications.

Reliable Global Supply: We maintain a robust and efficient supply chain, ensuring the timely and secure delivery of this essential chemical to your facilities worldwide.

Expert Technical Support: Our team of experienced chemists and technical specialists is readily available to offer comprehensive guidance on product application, safe handling, and storage.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our manufacturing and distribution processes.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Boron Trifluoride Diethyl Etherate Complex. We are ready to support your most complex chemical challenges.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Corrosive (GHS05), Acute Toxicity (GHS06), Health Hazard (GHS08)

Hazard Statements: Highly flammable liquid and vapor; causes severe skin burns and eye damage; toxic if inhaled; may cause respiratory irritation; suspected of causing genetic defects.

UN Number: UN 2604

Hazard Class: 8 (Corrosive Substances), 3 (Flammable Liquids)

Packing Group: I

GHS02: Flammable

GHS02: Flammable GHS05: Corrosive

GHS05: Corrosive GHS06: Acute Toxicity

GHS06: Acute Toxicity GHS08: Health Hazard

GHS08: Health Hazard