High-Purity Acrylonitrile (CAS 107-13-1) from Aure Chemical – Your Trusted Source

Aure Chemical is a leading global supplier of Acrylonitrile (AN), also systematically known as Propenenitrile or Vinyl cyanide. This highly reactive and versatile chemical monomer is one of the most critical building blocks in the polymer industry. Recognized for its unique double bond and nitrile group, our high-purity Acrylonitrile is an indispensable precursor for manufacturing a vast array of synthetic fibers, plastics, and rubbers that are integral to everyday life, from textiles and automotive components to consumer goods and construction materials.

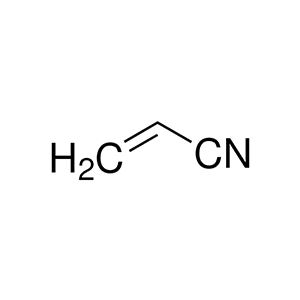

Basic Information of Acrylonitrile

Acrylonitrile (CAS No. 107-13-1) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your most demanding polymerization and synthesis applications:

| CAS No.: | 107-13-1 |

|---|

| EC No.: | 203-466-5 |

|---|

| Linear Formula: | CH₂=CH–CN |

|---|

| Molecular Weight: | 53.06 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Clear, colorless to pale yellow liquid. |

|---|

| Melting point: | -83 °C (lit.) |

|---|

| Boiling point: | 77 °C (lit.) |

|---|

| Density: | 0.806 g/mL at 20 °C |

|---|

| Solubility: | Moderately soluble in water; miscible with most organic solvents like alcohols, ethers, and hydrocarbons. |

|---|

| Flash point: | 32 °F |

|---|

| Nature: | Highly flammable liquid and vapor, toxic, rapidly polymerizes under certain conditions. |

|---|

| RIDADR: | UN 1093 3/PG 1 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Acrylonitrile ensures a reliable and efficient component for your critical manufacturing processes, backed by stabilizers to prevent premature polymerization.

Primary Applications of Acrylonitrile (AN)

Acrylonitrile's unique structure and high reactivity enable its broad utility as a monomer for various polymerization processes, leading to a diverse range of end products:

Acrylic Fibers and Modacrylic Fibers:

The largest application of AN is in the production of acrylic fibers and modacrylic fibers. These fibers are known for their softness, warmth, durability, and resistance to sunlight and chemicals, making them ideal for sweaters, socks, blankets, carpets, and outdoor fabrics.

ABS (Acrylonitrile Butadiene Styrene) & SAN (Styrene Acrylonitrile) Resins:

AN is a crucial monomer in the synthesis of ABS resins, which are high-performance engineering plastics. ABS offers excellent impact strength, toughness, and rigidity, widely used in automotive parts, consumer electronics casings, pipes, and toys. SAN resins offer transparency and chemical resistance for applications like food containers and appliance parts.

Nitrile Butadiene Rubber (NBR):

Acrylonitrile is copolymerized with butadiene to produce Nitrile Butadiene Rubber (NBR), also known as nitrile rubber. NBR is highly resistant to oils, fuels, and other chemicals, making it essential for fuel hoses, seals, O-rings, and protective gloves in the automotive, oil & gas, and industrial sectors.

Adiponitrile Production:

Acrylonitrile can also be electrohydrodimerized to produce Adiponitrile, which is a key intermediate in the synthesis of hexamethylenediamine, the precursor for Nylon 6,6.

Other Specialty Polymers and Chemicals:

AN is used in the synthesis of various other specialty polymers, flocculants, and as an intermediate for other organic compounds, leveraging its nitrile functionality and vinyl group.

Why Choose Aure Chemical for Your Acrylonitrile (AN) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Acrylonitrile requirements, you benefit from:

Exceptional Purity & Stability: Our Acrylonitrile is manufactured to stringent purity specifications and includes appropriate stabilizers, ensuring optimal polymerization outcomes and preventing unwanted side reactions.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential monomer to your facilities worldwide, adhering to all strict safety and regulatory standards for highly flammable and toxic materials.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Acrylonitrile.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients handling this reactive material.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Acrylonitrile. We are ready to support your most demanding polymer and chemical manufacturing processes.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Acute Toxicity, Oral (GHS06), Acute Toxicity, Dermal (GHS06), Acute Toxicity, Inhalation (GHS06), Carcinogenicity (GHS08), Skin Sensitization (GHS07), Environmental Hazard (GHS09)

Hazard Statements: Highly flammable liquid and vapor; toxic if swallowed, in contact with skin, or inhaled; may cause cancer; may cause an allergic skin reaction; toxic to aquatic life with long lasting effects.

UN Number: UN 1093

Hazard Class: 3 (Flammable Liquids), 6.1 (Toxic substances)

Packing Group: I

GHS02: Flammable

GHS02: Flammable GHS06: Acute toxicity

GHS06: Acute toxicity GHS07: Skin sensitization

GHS07: Skin sensitization GHS08: Health hazard

GHS08: Health hazard GHS09: Environmental hazard

GHS09: Environmental hazard