Aure Chemical Delivers Excellence in High-Purity Sodium Hydroxide

Aure Chemical is a premier global supplier of high-quality Sodium Hydroxide (NaOH), universally known as Caustic Soda or Lye. Identified by its CAS number 1310-73-2, this inorganic compound is a highly versatile and indispensable strong alkali. It typically comes in solid forms like flakes, beads, or granular, or as a clear, colorless aqueous solution. Sodium Hydroxide is a cornerstone in countless industrial processes due to its powerful basicity and reactivity. It is extensively used in chemical manufacturing, pulp and paper production, water treatment, soap and detergent manufacturing, textile processing, and alumina refining. Aure Chemical's unwavering commitment to excellence ensures that our Sodium Hydroxide meets the stringent purity and performance requirements for your most demanding industrial applications, guaranteeing consistency, safety, and reliability.

Basic Information of Sodium Hydroxide

Sodium Hydroxide (CAS No. 1310-73-2) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 1310-73-2 |

|---|

| EC No.: | 215-185-5 |

|---|

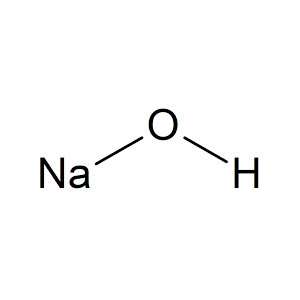

| Linear Formula: | NaOH |

|---|

| Molecular Weight: | 39.99711 |

|---|

| Appearance: | White, odorless solid (flakes, pellets, granules) |

|---|

| Melting Point: | 681 °C(lit.) |

|---|

| Boiling Point: | 1390°C |

|---|

| Density: | 1.515 g/mL at 20 °C |

|---|

| Solubility: | Highly soluble in water, releasing significant heat. Also soluble in ethanol and methanol. |

|---|

| Hygroscopic & Deliquescent: | Readily absorbs moisture and carbon dioxide from the air. |

|---|

| Corrosivity: | Highly corrosive to skin, eyes, and certain metals. Requires careful handling. |

|---|

| RIDADR: | UN 1823 8/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Sodium Hydroxide ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse industrial needs.

Primary Applications of Sodium Hydroxide

Sodium Hydroxide's powerful basicity and versatility make it a fundamental chemical with extensive applications across various industries:

Chemical Manufacturing:

It is a primary raw material in the production of a vast array of chemicals, including organic chemicals, inorganic compounds, and various sodium salts. It's crucial for acid neutralization, pH adjustment, and as a reactant in numerous synthetic processes.

Pulp and Paper Industry:

Sodium Hydroxide is extensively used in the Kraft process for pulping wood into paper, helping to dissolve lignin and separate cellulose fibers. It is also used in paper bleaching and deinking processes.

Water Treatment:

It is employed for pH adjustment and neutralization of acidic wastewater, coagulation, and flocculation in municipal and industrial water treatment plants to remove heavy metals and other impurities.

Soap and Detergent Manufacturing:

A key ingredient in the saponification process to produce soaps and detergents. It reacts with fats and oils to create soap, and is also used in the formulation of various cleaning products.

Alumina Production (Bayer Process):

Sodium Hydroxide is vital in the Bayer process for refining bauxite ore to produce alumina, which is then used to manufacture aluminum metal.

Textile Industry:

Used in the mercerization of cotton to enhance its strength, luster, and dye uptake. It also finds applications in fabric scouring and bleaching.

Petroleum and Natural Gas:

Employed in refineries to remove acidic impurities (e.g., hydrogen sulfide, carbon dioxide) from crude oil and natural gas streams.

Food Industry:

Used for various purposes including fruit and vegetable peeling, chocolate and cocoa processing, caramel coloring production, and poultry scalding. (Food-grade NaOH must be used for these applications).

Why Choose Aure Chemical for Your Sodium Hydroxide Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Sodium Hydroxide requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Sodium Hydroxide is manufactured to stringent purity specifications, crucial for ensuring optimal performance and efficiency in your industrial processes, from chemical synthesis to water treatment.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential alkali in various forms (solid or solution) to your facilities worldwide, adhering to all strict safety and regulatory standards for corrosive materials.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Sodium Hydroxide, emphasizing safety protocols due to its corrosive nature.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients and the safe handling of hazardous materials.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Sodium Hydroxide. We're ready to support your most demanding and innovative industrial processes.

Hazards Classification

GHS Classification: Corrosive (GHS05), Acute Toxicity (GHS07)

Hazard Statements: Causes severe skin burns and eye damage; harmful if swallowed.

UN Number: UN 1823

Hazard Class: 8 (Corrosive Substances)

Packing Group: II

GHS05: Corrosive

GHS05: Corrosive GHS07: Acute toxicity

GHS07: Acute toxicity