Aure Chemical Delivers Excellence in Sodium Thiosulfate Pentahydrate

Aure Chemical is a premier global supplier of high-quality Sodium Thiosulfate Pentahydrate (Na₂S₂O₃·5H₂O). Identified by its CAS number 10102-17-7, this hydrated form of Sodium Thiosulfate is commonly known as Hypo or sometimes by its historical name related to Glauber's salt. It appears as white, translucent crystals, highly soluble in water, and is the most common and widely utilized form of Sodium Thiosulfate in commerce. Its powerful reducing properties and ability to form complexes with metal ions make it an indispensable chemical across diverse industries, from its essential role as a photographic fixer to its modern uses in water treatment, medical applications, and analytical chemistry. Aure Chemical's commitment to excellence ensures that our Sodium Thiosulfate Pentahydrate meets the stringent purity and performance requirements for your most demanding applications, guaranteeing consistency and reliability.

Basic Information of Sodium Thiosulfate Pentahydrate

Sodium Thiosulfate Pentahydrate (CAS No. 10102-17-7) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your operations:

| CAS No.: | 10102-17-7 |

|---|

| EC No.: | 600-156-5 |

|---|

| Linear Formula: | Na₂S₂O₃·5H₂O |

|---|

| Molecular Weight: | 248.18 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Melting point: | 48.5 °C |

|---|

| Density: | 1.01 g/mL at 25 °C |

|---|

| Solubility: | Highly soluble in water. Insoluble in alcohol. |

|---|

| Hygroscopicity: | Tends to effloresce (lose water of crystallization) in dry air above 33 °C and deliquesce (absorb moisture and dissolve) in very humid air. |

|---|

| RIDADR: | Strong reducing agent. Generally stable under normal conditions but can decompose in acidic solutions, releasing sulfur and sulfur dioxide. |

|---|

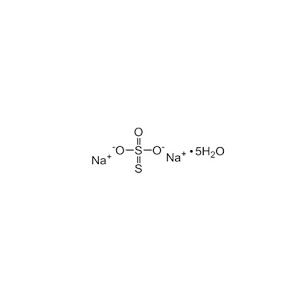

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Sodium Thiosulfate Pentahydrate ensures a reliable and efficient component for your critical processes.

Primary Applications of Sodium Thiosulfate Pentahydrate

Sodium Thiosulfate Pentahydrate's strong reducing capabilities, ease of handling, and versatility make it an incredibly valuable and widely used compound with applications across numerous industries:

Photography (Fixer):

It is universally known as "Hypo" and is the primary fixing agent in traditional black-and-white and color photographic processes. It dissolves unexposed silver halides from photographic film and paper, stabilizing the image and making it light-fast.

Water Treatment and Dechlorination:

It is widely used as an effective dechlorinating agent to neutralize residual chlorine and chloramines from municipal drinking water, wastewater, swimming pools, and industrial process water. This is vital before discharge or when chlorine interferes with other chemical processes, such as in brewing, aquaculture, and dialysis.

Medical and Pharmaceutical Applications:

Sodium Thiosulfate is used as an antidote for cyanide poisoning, converting cyanide to the less toxic thiocyanate. It is also applied topically to treat certain fungal skin infections (e.g., tinea versicolor) and has uses in some chemotherapy regimens to reduce heavy metal toxicity.

Analytical Chemistry:

It is a standard reducing agent and titrant in iodometric titrations, used to accurately determine the concentration of oxidizing agents (e.g., chlorine, iodine) in various samples and solutions.

Gold and Silver Extraction:

In the mining industry, particularly in hydrometallurgy, it is explored and used as a less toxic alternative to cyanide for leaching gold and silver from ores, especially for complex or refractory ores.

Textile and Paper Industries:

It can be used as a dechlorinating agent after bleaching processes in both textile and paper manufacturing, preventing damage to fibers from residual bleaches.

Why Choose Aure Chemical for Your Sodium Thiosulfate Pentahydrate Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Sodium Thiosulfate Pentahydrate requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Sodium Thiosulfate Pentahydrate is manufactured to stringent purity specifications, crucial for achieving precise results in analytical applications, effective water treatment, and reliable photographic processes.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all strict safety and regulatory standards.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Sodium Thiosulfate Pentahydrate.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Sodium Thiosulfate Pentahydrate. We're ready to support your most demanding and innovative industrial processes.