Get the Best Bis(trifluoromethanesulfonyl)imide (HNTf2, CAS 82113-65-3) for Your Process – From Aure Chemical

Aure Chemical is a premier global supplier of high-quality Bis(trifluoromethanesulfonyl)imide, commonly abbreviated as HNTf2 or Tf2NH, and also known as Bistriflimide. Identified by its CAS number 82113-65-3, this compound is a white crystalline solid recognized as one of the strongest commercially available Brønsted acids, often classified as a superacid. It combines exceptional acidity with high thermal stability, non-oxidizing properties, and unique anionic characteristics, making it an incredibly versatile and powerful reagent in numerous advanced chemical applications. HNTf2 is indispensable as a highly efficient acid catalyst in complex organic synthesis, a crucial proton source in electrochemical systems, and a fundamental building block for a new generation of highly stable and conductive ionic liquids. Aure Chemical is committed to providing Bis(trifluoromethanesulfonyl)imide that meets stringent purity and performance requirements, ensuring consistent and reliable results for your most demanding industrial and research applications. Partner with us for a dependable supply of this critical chemical.

Basic Information of Bis(trifluoromethanesulfonyl)imide

Bis(trifluoromethanesulfonyl)imide (HNTf2, CAS No. 82113-65-3) is meticulously produced and rigorously tested to meet stringent quality standards. We offer various grades to suit your specific application requirements:

| CAS No.: | 82113-65-3 |

|---|

| EC No.: | 435-300-4 |

|---|

| Linear Formula: | HN(SO₂CF₃)₂ |

|---|

| Molecular Weight: | 281.15 |

|---|

| Appearance: | White crystalline solid. |

|---|

| Melting Point: | 138-142 °C |

|---|

| Boiling point: | 90-91 °C(lit.) |

|---|

| Density: | 1.36 |

|---|

| Solubility: | Soluble in water and many polar organic solvents (e.g., ethers, alcohols, acetonitrile). |

|---|

| Stability: | Excellent thermal stability; highly resistant to oxidation. |

|---|

| Purity: | Available in high purity grades (e.g., 99% min) for sensitive catalytic and electrochemical applications. |

|---|

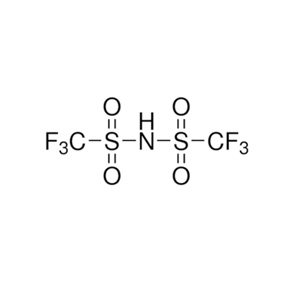

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity HNTf2 ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse synthetic and industrial applications.

Primary Applications of Bis(trifluoromethanesulfonyl)imide (HNTf2)

Bis(trifluoromethanesulfonyl)imide's extreme acidity, thermal stability, and unique anionic properties make it an invaluable reagent with significant applications in various advanced chemical processes:

Acid Catalyst in Organic Synthesis:

As a powerful non-oxidizing superacid, HNTf2 is an exceptionally effective acid catalyst for a wide range of organic reactions, often under mild conditions. This includes:

Esterification and Amidation: Efficiently catalyzes the formation of esters and amides.

Polymerization: Used as an initiator or catalyst for the polymerization of various monomers, particularly in cationic polymerization, influencing molecular weight and polymer properties.

Friedel-Crafts Reactions: Promotes alkylation and acylation reactions on aromatic compounds.

Protecting Group Chemistry: Effective in the cleavage of acid-sensitive protecting groups.

Precursor for Ionic Liquids:

The bis(trifluoromethanesulfonyl)imide anion (NTf₂⁻) is a key component in the synthesis of a vast array of ionic liquids. Ionic liquids based on the NTf₂⁻ anion exhibit excellent thermal stability, high ionic conductivity, broad electrochemical windows, and often low viscosity, making them ideal for applications in:

Electrolytes: For batteries, supercapacitors, and fuel cells.

Solvents: In catalysis, separations, and electrodeposition.

Proton Source in Electrochemistry:

Its strong acidity and high proton conductivity make it valuable as a proton source or electrolyte component in certain electrochemical systems.

Pharmaceutical and Agrochemical Production:

HNTf2 is a crucial reagent in the synthesis of complex active pharmaceutical ingredients (APIs) and agrochemicals. Its ability to catalyze highly selective and efficient reactions with high yields is invaluable in fine chemical manufacturing.

Alternative to Perchloric Acid:

In some applications, HNTf2 can serve as a safer and more stable alternative to highly corrosive and potentially explosive perchloric acid.

Its role in ionic liquids and electrochemical systems is discussed in TFSI and triflate salts in electrochemistry.

For a broader view of how triflimide acids relate to triflate chemistry,

refer to the overview of triflic acid and triflate chemistry.

Why Choose Aure Chemical for Your Bis(trifluoromethanesulfonyl)imide (HNTf2) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your HNTf2 requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Bis(trifluoromethanesulfonyl)imide is manufactured to stringent purity specifications, crucial for achieving optimal and reproducible results in sensitive catalytic processes, electrochemical research, and demanding synthetic reactions.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this essential superacid to your facilities worldwide, with flexible packaging options to meet your specific needs.

Expert Technical Support: Our dedicated team of specialists is readily available to offer comprehensive guidance on product application, safe handling, optimal storage, and usage in your specific chemical processes, ensuring safety and efficiency when working with a superacid.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and sustainable sourcing practices.

Customized Solutions: We understand that different applications may require specific purity levels. We are open to discussing customized solutions to meet your exact requirements.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Bis(trifluoromethanesulfonyl)imide (HNTf2). We're ready to empower your most advanced chemical synthesis and industrial innovations with an unwavering commitment to quality and excellence.