Aure Chemical: Your Trusted Source for High-Quality Methyl tert-Butyl Ether (MTBE)

Aure Chemical is a leading supplier of Methyl tert-Butyl Ether (MTBE), a well-known organic compound renowned for its unique chemical properties. While historically recognized for its role in fuel, MTBE remains an indispensable chemical for a variety of industrial, pharmaceutical, and laboratory applications due to its excellent solvency, stability, and high purity. We are committed to providing top-grade MTBE that consistently meets rigorous industry standards, ensuring reliable performance for your demanding processes.

Basic Information of Methyl tert-Butyl Ether

Methyl tert-Butyl Ether (CAS No. 1634-04-4) is a clear, colorless liquid with a distinctive, pungent odor. Its specific physical and chemical characteristics contribute to its broad utility:

| CAS No.: | 1634-04-4 |

|---|

| EC No.: | 216-653-1 |

|---|

| Linear Formula: | C₅H₁₂O |

|---|

| Molecular Weight: | 88.15 |

|---|

| Appearance: | Clear, colorless liquid |

|---|

| Odor: | Distinctive, pungent (ether-like) |

|---|

| Melting Point: | -108.6 °C |

|---|

| Boiling point | 55.2 °C |

|---|

| Density: | 0.7404 |

|---|

| Solubility: | Moderately soluble in water; highly miscible with most organic solvents. |

|---|

| Flash Point: | -10 °C |

|---|

| Purity: | Available in high-purity grades to ensure optimal performance in sensitive applications. |

|---|

| RIDADR: | UN 2398 3/PG 2 |

|---|

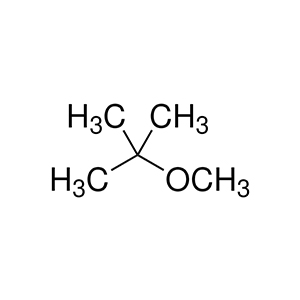

| Chemical Structure: |  |

|---|

These properties enable MTBE to serve effectively as a solvent, a reaction medium, and a versatile building block in chemical synthesis.

Versatile Applications of Methyl tert-Butyl Ether

Despite its historical phase-out as a primary fuel oxygenate in some regions, Aure Chemical's Methyl tert-Butyl Ether maintains significant importance across numerous industrial and specialized applications:

Chemical Solvent: An excellent solvent for a wide range of organic compounds, utilized in various chemical processes, extractions, and purifications.

Chemical Intermediate: Serves as a key intermediate in the synthesis of other chemicals, including isobutene derivatives, and is used in the production of various industrial compounds.

Pharmaceutical Industry: Employed as a solvent in the synthesis, purification, and recrystallization processes of active pharmaceutical ingredients (APIs) and other drug intermediates.

Laboratory & Research: A common solvent in organic synthesis and analytical procedures due to its inertness, high purity, and ease of evaporation. It is also used as an extractant.

Polymer Manufacturing: Can be used as a polymerization medium or an auxiliary agent in the production of certain polymers.

Industrial Processes: Finds application in various industrial processes requiring a versatile solvent with specific solvency and volatility characteristics.

Why Choose Aure Chemical for Your Methyl tert-Butyl Ether Supply?

Aure Chemical is dedicated to being your reliable partner for high-quality chemical solutions. When you choose us for your Methyl tert-Butyl Ether requirements, you benefit from:

Assured Quality: Our MTBE is rigorously tested to ensure high purity and consistent performance, meeting or exceeding stringent industry specifications.

Reliable Supply Chain: We maintain a robust and efficient global supply chain to ensure timely and secure delivery, supporting your continuous operational needs.

Technical Expertise: Our knowledgeable team is always available to provide comprehensive support and answer any technical questions you may have regarding product application and handling.

Commitment to Safety & Sustainability: We adhere to strict safety, environmental, and regulatory protocols in all our operations, ensuring responsible sourcing and delivery of our products.

Partner with Aure Chemical for a seamless and dependable supply of Methyl tert-Butyl Ether. We are ready to assist you in finding the perfect solution for your specific application requirements.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Health Hazard (GHS08), Environmental Hazard (GHS09)

Hazard Statements: Highly flammable liquid and vapor; may cause drowsiness or dizziness; suspected of causing cancer; toxic to aquatic life with long lasting effects.

UN Number: UN 2398

Hazard Class: 3 (Flammable Liquids)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS08: Health hazard

GHS08: Health hazard GHS09: Environmental hazard

GHS09: Environmental hazard