Aure Chemical: Your Premier Source for High-Purity Dimethylamine (CAS 124-40-3)

Aure Chemical is a leading global supplier of Dimethylamine (DMA), also systematically known as N-Methylmethanamine. This fundamental secondary amine is an indispensable building block in the chemical industry, recognized for its unique reactivity and broad utility. Our high-purity Dimethylamine is a crucial intermediate for manufacturing an extensive array of products, from essential pharmaceuticals and agrochemicals to widely used solvents and critical rubber chemicals.

Basic Information of Dimethylamine

Dimethylamine (CAS 124-40-3) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 124-40-3 |

|---|

| EC No.: | 204-697-4 |

|---|

| Linear Formula: | (CH₃)₂NH |

|---|

| Molecular Weight: | 45.08 |

|---|

| Appearance: | Colorless gas at room temperature and pressure; typically supplied as a compressed liquid or aqueous solution. |

|---|

| Odor: | Strong, pungent, fishy, ammoniacal odor. |

|---|

| Melting Point: | −93 °C(lit.) |

|---|

| Boiling point: | 7 °C(lit.) |

|---|

| Density: | 0.89 g/mL at 25 °C |

|---|

| Solubility: | Highly soluble in water and most organic solvents (e.g., ethanol, ether). |

|---|

| Flash point: | 60 °F |

|---|

| Nature: | Highly flammable gas/liquid, corrosive, alkaline. |

|---|

| RIDADR: | UN 1032 2.1 |

|---|

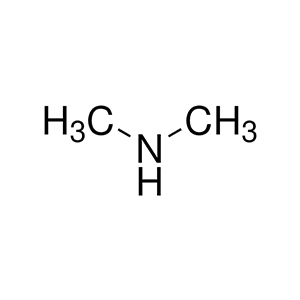

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Dimethylamine ensures a reliable and efficient component for your complex manufacturing and synthesis processes.

Primary Applications of Dimethylamine (DMA)

Dimethylamine's reactivity as a secondary amine, particularly its ability to undergo various organic reactions, makes it an incredibly versatile intermediate for a vast spectrum of industrial products:

Solvents (DMF & DMAC):

One of the largest applications of DMA is in the production of high-performance solvents like N,N-Dimethylformamide (DMF) and N,N-Dimethylacetamide (DMAC). These solvents are widely used in chemical reactions, as spinning solvents for fibers, and in various industrial cleaning processes due to their excellent solvency and high boiling points.

Pharmaceutical Synthesis:

DMA is a critical precursor for synthesizing numerous active pharmaceutical ingredients (APIs), including various antihistamines, local anesthetics, and other complex drug molecules. Its amino group readily participates in alkylation, acylation, and condensation reactions.

Agrochemical Manufacturing:

It is extensively used in the production of various agrochemicals, such as herbicides (e.g., thiocarbamates, dithiocarbamates) and fungicides. Derivatives of DMA contribute to the efficacy and selectivity of these crop protection agents.

Rubber Chemicals:

DMA serves as a key intermediate in the synthesis of rubber vulcanization accelerators (e.g., thiuram disulfides) and antioxidants, which are vital for improving the processing, strength, and durability of rubber products like tires.

Surfactants:

It is used in the production of specialty surfactants, including amine oxides and quaternary ammonium compounds, which find applications in detergents, personal care products, and industrial cleaning formulations due to their foaming, emulsifying, and conditioning properties.

Water Treatment Chemicals:

Dimethylamine derivatives are employed in certain water treatment processes, particularly as flocculants or coagulants for impurity removal.

Dyes and Pigments:

In some cases, DMA is utilized in the synthesis of specific types of dyes and pigments, contributing to color characteristics or enhancing material interactions.

Dimethylamine (DMA) Supply at Aure Chemical

At Aure Chemical, we primarily supply Dimethylamine (DMA) as high-purity aqueous solutions. These solutions offer enhanced safety and ease of handling compared to anhydrous gaseous DMA, making them the preferred choice for most industrial applications. We offer various concentrations to meet diverse manufacturing needs.

Should your specific process require gaseous Dimethylamine, please contact us directly and in advance to discuss your requirements. Supplying DMA in its gaseous form involves specialized handling and logistics, and we will need to confirm feasibility and specific arrangements to ensure safe and efficient delivery. Our team is ready to assist you with the optimal solution for your DMA needs.

Why Choose Aure Chemical for Your Dimethylamine (DMA) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Dimethylamine requirements, you benefit from:

Exceptional Purity & Consistency: Our Dimethylamine is manufactured to stringent purity specifications, ensuring optimal and predictable reactivity in your critical synthesis processes and consistent quality in your end products.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all safety and regulatory standards for compressed gases and hazardous liquids.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Dimethylamine.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients handling this reactive and volatile material.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Dimethylamine. We are ready to support your most demanding and innovative chemical manufacturing processes.

Hazards Classification

GHS Classification: Flammable Gas (GHS02), Acute Toxicity, Inhalation (GHS06), Skin Corrosion (GHS05), Serious Eye Damage (GHS05)

Hazard Statements: Extremely flammable gas; toxic if inhaled; causes severe skin burns and eye damage.

UN Number: UN 1032

Hazard Class: 2.1 (Flammable gases), 8 (Corrosive substances)

Packing Group: Not applicable

GHS02: Flammable

GHS02: Flammable GHS06: Acute toxicity

GHS06: Acute toxicity GHS05: Corrosive

GHS05: Corrosive