Aure Chemical Delivers Excellence in High-Purity Aniline (CAS 62-53-3)

Aure Chemical stands as a leading global supplier of Aniline, also widely known as Aminobenzene or Phenylamine. This foundational aromatic amine is one of the most significant and extensively used intermediates in the chemical industry. Recognized for its unique reactivity and versatility, high-purity Aniline from Aure Chemical is an indispensable building block for manufacturing an immense array of products, ranging from advanced polyurethanes and vibrant dyes to critical rubber chemicals and life-saving pharmaceuticals.

Basic Information of Aniline

Aniline (CAS No. 62-53-3) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance essential for your most demanding applications:

| CAS No.: | 62-53-3 |

|---|

| EC No.: | 200-539-3 |

|---|

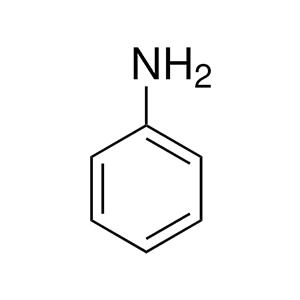

| Linear Formula: | C₆H₅NH₂ |

|---|

| Molecular Weight: | 93.13 |

|---|

| Appearance: | Oily, colorless to pale yellow liquid when pure; darkens upon exposure to air and light. |

|---|

| Odor: | Characteristic, slightly fishy odor. |

|---|

| Melting Point: | -6 °C (lit.) |

|---|

| Boiling point: | 184 °C (lit.) |

|---|

| Density: | 1.022 g/mL at 25 °C (lit.) |

|---|

| Solubility: | Slightly soluble in water; readily soluble in most organic solvents like ethanol, ether, and benzene. |

|---|

| Flash point: | 76 °C |

|---|

| Nature: | Combustible, toxic, readily oxidizes in air. |

|---|

| RIDADR: | UN 1547 6.1/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Aniline ensures a reliable and efficient component for your complex manufacturing and synthesis processes.

Primary Applications of Aniline

Aniline's reactivity, particularly its amino group and aromatic ring, makes it a highly versatile intermediate for a vast spectrum of industrial and consumer products:

Polyurethane Production (MDI):

The largest application of Aniline is in the synthesis of methylenedianiline (MDA), which is then converted into methylene diphenyl diisocyanate (MDI). MDI is a key raw material for producing polyurethanes, widely used in foams (insulation, furniture, automotive), coatings, adhesives, and elastomers.

Dyes and Pigments:

Aniline is a crucial precursor for a wide range of synthetic dyes and pigments, including azo dyes, triphenylmethane dyes, and indigo. These are used in textiles, printing inks, and paints.

Rubber Chemicals:

It is extensively used in the production of various rubber chemicals, such as accelerators, antioxidants, and antiozonants. These additives are essential for improving the processing, performance, and durability of rubber products like tires, hoses, and belts.

Pharmaceuticals:

Aniline serves as a fundamental building block in the synthesis of numerous active pharmaceutical ingredients (APIs) and pharmaceutical intermediates. It is used in the production of analgesics, sulfa drugs, and other complex organic molecules.

Agrochemicals:

It is employed in the manufacturing of various agrochemicals, including herbicides, fungicides, and insecticides, contributing to the efficacy and selectivity of these crop protection agents.

Explosives:

In certain contexts, Aniline is used in the synthesis of some explosive materials.

Other Specialty Chemicals:

It also finds application in the production of photographic chemicals, optical brighteners, and various other fine and specialty chemicals.

Why Choose Aure Chemical for Your Aniline Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Aniline requirements, you benefit from:

Exceptional Purity & Consistency: Our Aniline is manufactured to stringent purity specifications, critical for complex downstream syntheses, ensuring optimal reaction outcomes and high-quality end products.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all safety and regulatory standards for hazardous materials.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Aniline.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients handling this reactive and toxic material.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Aniline. We are ready to support your most demanding and innovative chemical manufacturing processes.

Hazards Classification

GHS Classification: Acute Toxicity, Oral (GHS06), Acute Toxicity, Inhalation (GHS06), Acute Toxicity, Dermal (GHS06), Skin Sensitization (GHS07), Carcinogenicity (GHS08), Specific Target Organ Toxicity, Repeated Exposure (GHS08), Environmental Hazard (GHS09)

Hazard Statements: Toxic if swallowed, inhaled, or in contact with skin; may cause an allergic skin reaction; suspected of causing cancer; causes damage to organs (blood) through prolonged or repeated exposure; toxic to aquatic life with long lasting effects.

UN Number: UN 1547

Hazard Class: 6.1 (Toxic substances)

Packing Group: II

GHS06: Acute toxicity

GHS06: Acute toxicity GHS07: Skin sensitization

GHS07: Skin sensitization GHS08: Health hazard

GHS08: Health hazard GHS09: Environmental hazard

GHS09: Environmental hazard