Your BPDA Partner – Aerospace-Grade Polyimide Monomer from Aure Chemical

3,3',4,4'-Biphenyltetracarboxylic dianhydride (BPDA, CAS 2420-87-3) is a highly rigid aromatic

dianhydride monomer widely used in the synthesis of ultra-high-performance polyimides.

Owing to its biphenyl backbone, BPDA-based polyimides exhibit exceptional thermal stability,

extremely low coefficient of thermal expansion (CTE), high modulus, and long-term dimensional

stability under extreme thermal and mechanical conditions.

Basic Information of BPDA

| Product Name | 3,3',4,4'-Biphenyltetracarboxylic dianhydride |

|---|

| Abbreviation | BPDA |

|---|

| CAS Number | 2420-87-3 |

|---|

| Molecular Formula | C16H6O6 |

|---|

| Molecular Weight | 294.22 g/mol |

|---|

| Appearance | Off-white powder to crystal |

|---|

| Purity | ≥99.5% |

|---|

| Package | 1kg/bottle, 20kg/drum, or customized |

|---|

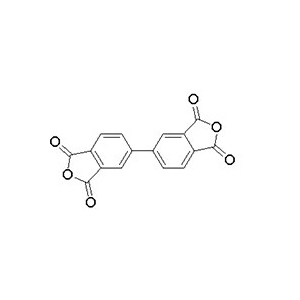

| Molecular Structure |  |

|---|

Key Properties

Extremely high thermal stability and glass transition temperature due to rigid biphenyl structure

Very low coefficient of thermal expansion (CTE), ideal for dimensional stability in extreme environments

High modulus and mechanical strength in cured polyimide systems

Excellent long-term thermal aging resistance and oxidative stability

Best suited for structural and insulation polyimides where performance outweighs processability

Application Positioning of BPDA

BPDA is primarily positioned foraerospace and high-temperature insulation applications,

where extreme heat resistance, dimensional stability, and mechanical integrity are critical.

BPDA-based polyimides are commonly selected for aerospace structures, engine insulation,

thermal protection systems, and high-temperature composite matrices.

As a secondary application domain, BPDA is employed inhigh-temperature electronics and microelectronics,

particularly in power electronics, semiconductor insulation layers, and devices

operating under prolonged thermal stress, where reliability is prioritized over flexibility

and optical transparency.

Key Applications of BPDA

Aerospace and High-Temperature Insulation (Primary Application):

Used in aerospace-grade polyimide films, insulation layers, structural composites,

and thermal protection materials for aircraft, spacecraft, and propulsion systems

exposed to extreme temperatures and mechanical loads.

High-Temperature Electronics (Secondary Application):

Applied in polyimide dielectrics, passivation layers, and insulating films

for power devices, high-reliability semiconductor packaging, and electronics

operating in harsh thermal environments.

Other High-Performance Industrial Uses:

Utilized in specialty high-modulus fibers, high-temperature resistant coatings,

and research-driven polyimide systems where extreme rigidity and thermal endurance

are required.

Detailed COA / TDS / MSDS are available upon request.

Please Contact Us for more information.