Aure Chemical Delivers Excellence in BPADA

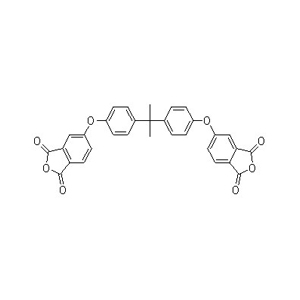

Bisphenol A dianhydride (BPADA, CAS 38103-06-9) is a bisphenol-based aromatic dianhydride

widely used as a monomer in the synthesis of high-performance and optically transparent

polyimides. Owing to its bulky isopropylidene structure, BPADA provides excellent solubility,

suppressed charge-transfer interactions, balanced thermal stability, and low dielectric

characteristics, making it particularly suitable for processing-oriented and flexible

polyimide systems.

Basic Information of BPADA

| Product Name | Bisphenol A dianhydride |

|---|

| Abbreviation | BPADA |

|---|

| CAS Number | 38103-06-9 |

|---|

| Molecular Formula | C31H20O8 |

|---|

| Molecular Weight | 520.49 g/mol |

|---|

| Appearance | White to light yellow powder or crystal |

|---|

| Purity | ≥99% |

|---|

| Package | 1kg/bottle, 20kg/drum, or customized |

|---|

| Molecular Structure |  |

|---|

Key Properties

Bulky bisphenol A backbone disrupts molecular packing and suppresses

charge-transfer complexes, enabling high optical transparency.

Excellent solubility and broad processing window for poly(amic acid)

solutions compared with rigid aromatic dianhydrides.

Moderate glass transition temperature (Tg ~200°C) suitable for

flexible and optoelectronic polymer systems.

Low dielectric constant and good electrical insulation performance

in derived polyimides.

Compatible with a wide range of aromatic and aliphatic diamines for

tuning mechanical and optical properties.

Application Positioning of BPADA

Primary Positioning – Processing-Oriented Polyimide Systems:

BPADA is primarily positioned for processing-oriented polyimide formulations,

where solubility, film-forming ability, and controllable viscosity are critical.

Its bulky non-planar structure enables easier polymer processing compared with

highly rigid dianhydrides such as BPDA or PMDA.

Secondary Positioning – Flexible Films, Coatings, and Adhesives:

BPADA is widely applied in

flexible polyimide films, coatings, and adhesive systems ,

where mechanical compliance, optical clarity, and dimensional stability are required.

Key Applications of BPADA

Processing-Oriented Polyimides:

Used as a solubility-enhancing dianhydride for polyimide systems requiring

wide processing windows, controlled molecular weight growth, and uniform

film or coating formation.

Flexible Films, Coatings, and Adhesives:

Applied in flexible substrates, protective coatings, and high-performance

adhesive formulations where toughness, transparency, and moderate heat

resistance are essential.

Detailed COA / TDS / MSDS are available upon request.

Please Contact Us for more information.