Aure Chemical Delivers Excellence in Boron Trifluoride Dibutyl Etherate

Aure Chemical is a leading supplier of Boron Trifluoride Dibutyl Etherate, a highly effective and widely used Lewis acid catalyst. This pale yellow to brown liquid is a stable and convenient form of Boron Trifluoride (BF₃), making it an invaluable reagent for a variety of industrial polymerization processes. Our Boron Trifluoride Dibutyl Etherate is manufactured to stringent purity standards, ensuring optimal catalytic activity and reliability for your most demanding applications.

Basic Information of Boron Trifluoride Dibutyl Etherate

Boron Trifluoride Dibutyl Etherate (CAS No. 593-04-4) is characterized by the following properties:

| CAS No.: | 593-04-4 |

|---|

| EC No.: | 209-783-5 |

|---|

| Linear Formula: | C₈H₁₈BF₃O |

|---|

| Molecular Weight: | 198.03 |

|---|

| Appearance: | Pale yellow to brown liquid |

|---|

| Density: | 0.959 g/mL at 25 °C(lit.) |

|---|

| Solubility | Soluble in many organic solvents; reacts with water and protic solvents. |

|---|

| Flash Point: | 70 °C |

|---|

| Nature: | Strong Lewis acid. |

|---|

| RIDADR: | UN 2922 or UN 3264 8(6.1)/PG 2(3) |

|---|

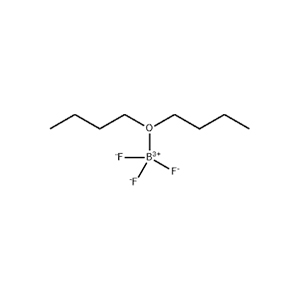

| Chemical Structure: |  |

|---|

These attributes make it a preferred catalyst in processes requiring efficient and controlled Lewis acid activity.

Main Functions and Applications of Boron Trifluoride Dibutyl Etherate

The catalytic capabilities of Aure Chemical's Boron Trifluoride Dibutyl Etherate make it indispensable in several key industrial and synthetic processes:

Synthesis of Polyformaldehyde Resin: Boron trifluoride dibutyl etherate is widely employed as a highly effective catalyst for the synthesis of polyformaldehyde resin, also known as polyoxymethylene (POM). It drives the cationic polymerization of formaldehyde or its cyclic oligomers (like trioxane) to produce this important engineering plastic.

Preparation of Ethylene-Oxygen Methylene Copolymer: This complex also plays a crucial role as a catalyst in the preparation of ethylene-oxygen methylene copolymers, and more broadly, in the cationic ring-opening polymerization of cyclic ethers like ethylene oxide. These copolymers find applications in various specialty polymers and materials.

Why Choose Aure Chemical for Your Boron Trifluoride Dibutyl Etherate Supply?

Aure Chemical is dedicated to being your reliable partner for high-quality chemical solutions. When you choose us for your Boron Trifluoride Dibutyl Etherate requirements, you benefit from:

Assured Purity & Performance: Our product undergoes stringent quality control to ensure high purity and consistent catalytic activity, vital for industrial polymerization processes.

Reliable Supply Chain: We maintain a robust and efficient global supply chain, ensuring timely and secure delivery of this valuable reagent.

Technical Expertise: Our knowledgeable team is always available to provide comprehensive support and answer any technical questions you may have regarding product application, handling, and safety.

Commitment to Quality & Safety: We adhere to the highest quality control, safety, and environmental standards throughout our operations, from manufacturing to distribution.

Partner with Aure Chemical for a seamless and dependable supply of high-quality Boron Trifluoride Dibutyl Etherate. We are ready to assist you in finding the perfect solution for your specific application requirements.

Hazards Classification

GHS Classification: Acute Toxicity (GHS06), Corrosive (GHS05), Flammable Liquid (GHS02)

Hazard Statements: Toxic if swallowed, in contact with skin or if inhaled; Causes severe skin burns and eye damage; Combustible liquid.

UN Number: UN 2922 or UN 3264

Hazard Class: 8 (Corrosive Substances)

Subsidiary Hazard Class (for UN 2922): 6.1 (Toxic Substances)

Packing Group: II or III

GHS06: Acute toxicity

GHS06: Acute toxicity GHS05: Corrosive

GHS05: Corrosive GHS02: Flammable

GHS02: Flammable