Aure Chemical: Your Reliable Source for High-Purity Tetrapropylammonium Bromide

Aure Chemical is a leading global supplier of high-quality Tetrapropylammonium Bromide (TPABr), also known as Tetra-n-propylammonium bromide and commonly abbreviated as TPAB. Identified by its CAS number 1941-30-6, TPABr is a quaternary ammonium salt appearing as a white crystalline solid. This versatile compound finds widespread use in various chemical applications, primarily as an effective phase-transfer catalyst (PTC) in organic synthesis, facilitating reactions between immiscible phases. Additionally, TPABr is crucial as a structure-directing agent (SDA) in the synthesis of zeolites and other microporous materials. Its ionic conductivity also makes it valuable as an electrolyte in electrochemical processes and as a reagent in polymer synthesis. Aure Chemical is committed to providing Tetrapropylammonium Bromide that meets stringent purity and performance requirements, ensuring consistent and reliable results for your critical applications. Partner with us for a dependable supply of this essential chemical.

Basic Information of Tetrapropylammonium Bromide

Tetrapropylammonium Bromide (TPABr, CAS No. 1941-30-6) is meticulously produced and rigorously tested to meet stringent quality standards. We offer various grades to suit your specific application requirements:

| CAS No.: | 1941-30-6 |

|---|

| EC No.: | 217-727-6 |

|---|

| Linear Formula: | C₁₂H₂₈BrN |

|---|

| Molecular Weight: | 266.27 |

|---|

| Appearance: | White crystalline solid. |

|---|

Melting Point:

| 266-272 °C |

|---|

| Density: | 1.1949 (rough estimate) |

|---|

| Solubility: | Soluble in water, alcohols, and some organic solvents. |

|---|

| Stability: | Stable under normal conditions. |

|---|

| Purity: | Available in various purity grades to meet specific industrial and research needs. |

|---|

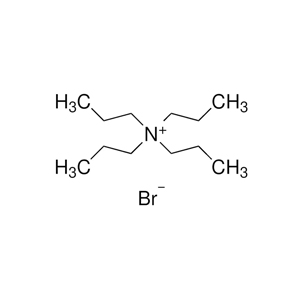

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity TPABr ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse synthetic and material science applications.

Primary Applications of Tetrapropylammonium Bromide (TPABr)

Tetrapropylammonium Bromide's unique properties make it a versatile reagent with significant applications in various fields:

Phase-Transfer Catalyst (PTC) in Organic Synthesis:

TPABr is widely used as a phase-transfer catalyst to facilitate reactions between reactants present in immiscible phases (e.g., aqueous and organic). It helps transport ions across the phase boundary, enhancing reaction rates in various alkylations, esterifications, and other organic transformations.

Structure-Directing Agent (SDA) in Zeolite Synthesis:

In the synthesis of zeolites and other microporous materials, TPABr acts as a structure-directing agent or template. Its presence during hydrothermal synthesis influences the formation of specific zeolite frameworks and pore structures.

Electrolyte in Electrochemical Applications:

Due to its ionic conductivity and relatively large cation size, TPABr is used as a supporting electrolyte in various electrochemical studies and applications, such as cyclic voltammetry and electrodeposition, particularly in non-aqueous solutions.

Reagent in Polymer Synthesis:

TPABr can be employed as a reagent or catalyst in certain polymerization reactions, influencing the molecular weight and properties of the resulting polymers.

Ion Pairing Agent in Chromatography:

In some chromatographic techniques, TPABr can act as an ion pairing agent to improve the separation and retention of ionic compounds.

Precursor for Other Quaternary Ammonium Compounds:

TPABr can serve as a starting material for the synthesis of other specialized quaternary ammonium salts with tailored properties for specific applications.

Why Choose Aure Chemical for Your Tetrapropylammonium Bromide (TPABr) Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your TPABr requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Tetrapropylammonium Bromide is manufactured to stringent purity specifications, ensuring optimal performance as a phase-transfer catalyst, structure-directing agent, and electrolyte in your critical applications.

Reliable Global Supply Chain: We maintain a robust and efficient global supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, with flexible packaging options to meet your specific needs.

Expert Technical Support: Our dedicated team of specialists is readily available to offer comprehensive guidance on product application, handling, storage, and optimal usage in your specific chemical processes.

Commitment to Quality & Responsible Stewardship: We adhere to the highest industry standards for quality management, environmental responsibility, and product stewardship across all our operations, ensuring peace of mind for our clients and sustainable sourcing practices.

Customized Solutions: We understand that different applications may require specific particle sizes or purity levels. We are open to discussing customized solutions to meet your exact requirements.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Tetrapropylammonium Bromide (TPABr). We're ready to support your advanced chemical synthesis and material science endeavors with an unwavering commitment to quality and service.