Aure Chemical: Your Trusted Source for High-Purity Propyl Acetate (CAS 109-60-4)

Aure Chemical is a leading global supplier of Propyl Acetate, commonly known as n-Propyl Acetate (systematically, Propyl Ethanoate). This highly versatile organic ester is valued for its excellent solvency, medium evaporation rate, and mild, fruity odor, making it a preferred choice across numerous industrial applications. Our high-purity Propyl Acetate is an indispensable solvent and chemical intermediate used in sectors ranging from printing inks and coatings to adhesives and personal care products.

Basic Information of Propyl Acetate

Propyl Acetate (CAS No. 109-60-4) is meticulously produced to meet stringent quality standards, ensuring exceptional purity and consistent performance for your diverse industrial needs:

| CAS No.: | 109-60-4 |

|---|

| EC No.: | 203-686-1 |

|---|

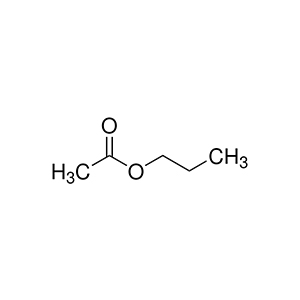

| Linear Formula: | CH₃COOCH₂CH₂CH₃ |

|---|

| Molecular Weight: | 102.13 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Odor: | Mild, fruity odor. |

|---|

| Melting Point: | -95 °C (lit.) |

|---|

| Boiling point: | 102 °C (lit.) |

|---|

| Density: | 0.888 g/mL at 25 °C (lit.) |

|---|

| Solubility: | Slightly soluble in water; miscible with most organic solvents. |

|---|

| Flash Point: | 55 °F |

|---|

| Purity: | Flammable liquid and vapor. |

|---|

| RIDADR: | UN 1276 3/PG 2 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Propyl Acetate ensures a reliable and efficient component for your manufacturing and formulation needs.

Primary Applications of Propyl Acetate

Propyl Acetate's unique combination of properties, including its solvent power, balanced evaporation profile, and agreeable aroma, makes it highly versatile for various industrial uses:

Solvent in Printing Inks:

It is a widely used solvent in flexographic and rotogravure printing inks, particularly for polyolefin films. It provides excellent solvency for resins, a balanced evaporation rate that prevents plate drying, and good flow properties, contributing to high-quality, vibrant print results.

Paints, Coatings, and Lacquers:

Propyl Acetate serves as an effective solvent for a broad range of resins, including nitrocellulose, acrylics, epoxies, and polyurethanes, used in automotive finishes, wood lacquers, and industrial coatings. Its medium evaporation rate helps achieve smooth film formation and prevents "blushing."

Adhesives and Sealants:

As a powerful solvent, Propyl Acetate is a key component in many adhesive and sealant formulations. It contributes to proper viscosity, ensures good wetting of surfaces, and allows for controlled drying times.

Chemical Intermediate:

Propyl Acetate can serve as a chemical intermediate in the synthesis of other organic compounds, although its primary role is as a solvent.

Fragrances and Flavorings:

Due to its mild, fruity scent, Propyl Acetate is used as a component in certain fragrances, perfumes, and as a flavor enhancer in some food applications, typically in very low concentrations.

Cosmetics and Personal Care:

It finds limited use in some cosmetic formulations where its solvent properties and mild odor are beneficial.

Why Choose Aure Chemical for Your Propyl Acetate Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Propyl Acetate requirements, you benefit from:

Exceptional Purity & Consistency: Our Propyl Acetate is manufactured to stringent purity specifications, ensuring optimal performance and compliance for your demanding applications.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential solvent to your facilities worldwide.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling, and optimal storage conditions for Propyl Acetate.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Propyl Acetate. We are ready to support your most intricate chemical formulations and processes.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Irritant (GHS07), Health Hazard (GHS08)

Hazard Statements: Highly flammable liquid and vapor; causes serious eye irritation; may cause drowsiness or dizziness.

UN Number: UN 1276

Hazard Class: 3 (Flammable Liquids)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS07: Irritant

GHS07: Irritant GHS08: Health Hazard

GHS08: Health Hazard