Methyltrichlorosilane (MTS, CH₃SiCl₃, CAS 75-79-6) is a pivotal organosilicon precursor in advanced materials synthesis, featuring a silicon atom bonded to one methyl group and three chlorine atoms. Its dual properties—high reactivity for efficient methyl group incorporation and volatility for seamless vapor-phase delivery—make it indispensable in the preparation of silicon-based materials across the semiconductor industry. In silicon carbide (SiC) semiconductor fabrication, MTS excels as a precursor for high-quality SiC films via chemical vapor deposition (CVD), enabling the creation of insulating layers, substrates, and protective coatings with superior thermal stability (up to 1600°C) and electrical performance (wide bandgap of 3.26 eV). This article delves into MTS's applications, process integration, and characterization techniques, underscoring its role in powering next-generation devices like power electronics and high-voltage transistors.

Chemical Profile and Key Properties

MTS is a colorless, fuming liquid with a boiling point of 66°C, density of 1.27 g/cm³, and high vapor pressure (140 mmHg at 20°C), facilitating precise gas-phase control in CVD reactors. Its reactivity stems from labile Si-Cl bonds, which decompose under heat to release HCl and form Si-C bonds: CH₃SiCl₃ + CH₄ + H₂ → SiC + 4 HCl. The methyl group supplies both silicon and carbon, promoting stoichiometric SiC growth with minimal defects. However, MTS's moisture sensitivity requires inert handling to avoid premature hydrolysis (CH₃SiCl₃ + 3 H₂O → CH₃Si(OH)₃ + 3 HCl), which could generate corrosive by-products. These attributes enable MTS to produce dense, crystalline SiC films ideal for demanding semiconductor environments.

Primary Applications in SiC Semiconductor Processes

Facilitating CVD Deposition of Silicon Carbide Films

MTS serves as the silicon source in CVD, reacting with methane (CH₄) and hydrogen (H₂) in hot-wall reactors to deposit epitaxial or polycrystalline SiC films. At temperatures of 1000-1500°C, MTS decomposes to form insulating layers or substrates for SiC devices, offering exceptional thermal conductivity (490 W/m·K) and breakdown strength (>2 MV/cm). These films are vital for MOSFETs, diodes, and sensors in electric vehicles and renewable energy systems.

Precise Film Growth Control

Adjusting MTS flow rates (0.1-10 sccm) and partial pressures allows fine-tuning of growth rates (1-20 μm/h) and C/Si ratios (0.9-1.1), ensuring films meet exact thickness (0.1-500 μm) and doping requirements. This controllability minimizes defects like micropipes, enhancing device reliability in high-power applications.

Surface Modification Capabilities

MTS introduces methyl groups via plasma-enhanced CVD, grafting onto SiC surfaces to improve wettability (contact angle >100°) and adhesion. This optimizes interfacial bonding in multilayer stacks, reducing delamination and enhancing durability for harsh environments like aerospace components.

Supporting Semiconductor Device Fabrication

MTS-derived SiC films function as gate dielectrics, passivation layers, or substrates throughout fabrication, directly influencing device performance. In TRISO nuclear fuel coatings, high MTS concentrations yield superhard SiC (42 GPa), illustrating its versatility in extreme conditions.

Process Integration in SiC Fabrication

Deposition Condition Control

Temperature (1200-1400°C) and pressure (10-100 Torr) are paramount in CVD; elevated temperatures promote β-SiC crystallinity, while low pressures curb nucleation. MTS/H₂ ratios (1:4-1:10) ensure stoichiometry, with simulations optimizing uniformity.

Reaction Chamber Optimization

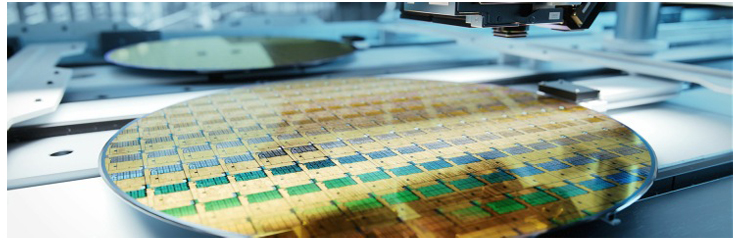

Hot-wall reactors with rotating susceptors and TaC linings provide uniform deposition (<5% variation on 200 mm wafers), accommodating MTS's corrosive by-products via sufficient mixing volumes.

Precursor Gas Handling

MTS is vaporized in heated bubblers (20-30°C) and delivered via mass flow controllers, mixed with H₂/Ar carriers in lines preheated to 80°C to prevent condensation and ensure controlled decomposition.

Post-Processing Procedures

Annealing (1400-1600°C in Ar) activates dopants and relieves stresses, while H₂ etching smooths surfaces (RMS <1 nm), boosting electron mobility (>100 cm²/V·s).

Film Performance Evaluation

Testing encompasses electrical (CV-IV for dielectric strength >5 MV/cm), thermal (laser flash for conductivity), and mechanical (nanoindentation for hardness) metrics to validate device suitability.

Characterization Techniques for MTS-Derived SiC Films

Structural Analysis: X-ray diffraction (XRD) assesses crystallinity (FWHM <0.5° for epitaxial films); transmission electron microscopy (TEM) reveals defects and polytypes.

Compositional Profiling: Secondary ion mass spectrometry (SIMS) quantifies C/Si ratios and impurities (<10^17 cm⁻³ Cl); Auger electron spectroscopy (AES) maps surface chemistry.

Morphological Examination: Atomic force microscopy (AFM) measures roughness (RMS <1 nm); scanning electron microscopy (SEM) evaluates thickness uniformity.

Electrical and Thermal Metrics: Hall effect probes carrier concentration (10^15-10^18 cm⁻³); deep-level transient spectroscopy (DLTS) identifies traps; Raman spectroscopy confirms TO mode at 796 cm⁻¹ for stoichiometry.

These techniques ensure compliance with fab standards like ISO 14644.

Challenges and Future Outlook

Challenges include HCl corrosion and gas-phase nucleation at high MTS flows, addressed by kinetic models. Future innovations involve MTS in selective epitaxy for 4H-SiC, with market growth to USD 2.5 billion by 2030 fueled by EVs and 5G.

Safety and Handling

Corrosive and flammable (GHS Skin Corr. 1B), MTS demands glovebox handling, HCl scrubbers, and PPE; consult SDS for fab protocols.

MTS's reactivity and volatility drive precise SiC CVD, with robust characterization ensuring high-performance films. Its integration propels SiC semiconductors toward efficient, sustainable electronics.