High-Purity Chloroauric Acid Hydrate from Aure Chemical – Your Trusted Source

Chloroauric acid hydrate, HAuCl₄·xH₂O, CAS No. 27988-77-8, is the most widely used crystalline form of tetrachloroauric(III) acid and a cornerstone precursor in gold chemistry. Supplied by Aure Chemical as bright yellow to orange-yellow crystalline powder or hydrated solid with high gold content (typically 49–50% Au), this highly hygroscopic compound readily dissolves in water to form the [AuCl₄]⁻ ion and serves as an efficient source of Au(III) for reduction to Au(0) nanoparticles, electrolytic gold deposition, preparation of gold catalysts, and synthesis of organogold complexes. Its exceptional reactivity and clean reduction behavior make it indispensable for producing monodisperse gold colloids in biosensors, plasmonics, drug delivery, and catalysis, as well as for high-purity gold coatings in electronics and jewelry finishing. Aure Chemical provides controlled hydration, precise Au assay, low impurity levels, and secure gold sourcing to ensure batch consistency and optimal performance in nanotechnology, plating, and research applications worldwide.

Basic Information of Chloroauric Acid Hydrate

Aure Chemical supplies Chloroauric Acid Hydrate as a premium Au(III) precursor with verified high gold content and exceptional purity for reduction, deposition, and synthesis applications.

| CAS No. | 27988-77-8 |

|---|

| EC No. | 240-948-4 (anhydrous basis) |

|---|

| Chemical Formula | HAuCl₄·xH₂O |

|---|

| Molecular Weight | 339.79 g/mol (anhydrous basis) |

|---|

| Appearance | Bright yellow to orange-yellow crystalline powder or hydrated solid |

|---|

| Odor | Odorless to slight chlorine |

|---|

| Melting point | Decomposes before melting (~30–50 °C for hydrate) |

|---|

| Boiling point | Not applicable (decomposes) |

|---|

| Density | approx. 2.4 g/cm³ (anhydrous); hydrate varies |

|---|

| Solubility | Highly soluble in water (>1000 g/L); soluble in ethanol, acetone, ethyl acetate |

|---|

| Nature (hazards) | Causes severe skin burns and eye damage, may cause allergic skin reaction, harmful if swallowed or inhaled, toxic to aquatic life |

|---|

| RIDADR | UN 3260, Corrosive solid, acidic, inorganic, n.o.s. (Chloroauric acid hydrate), Class 8, Packing Group III |

|---|

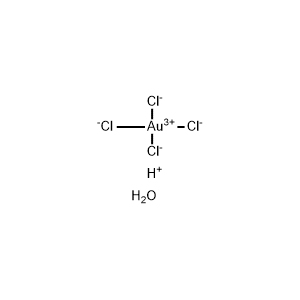

| Chemical Structure |  |

|---|

Aure Chemical offers customizable options including gold content specification (49–50% Au typical), controlled hydration level (x = 3–4 common), purity grades, and moisture-protected packaging to meet your nanoparticle, plating, or synthesis process requirements.

Primary Applications of Chloroauric Acid Hydrate

Chloroauric Acid Hydrate is the standard Au(III) source for gold reduction and deposition processes across nanotechnology, surface finishing, and catalysis.

Gold Nanoparticle & Colloid Synthesis

Serves as the primary gold precursor for controlled reduction (citrate, borohydride, or seed-mediated methods) to produce monodisperse Au nanoparticles for biosensors, drug delivery, plasmonics, and catalysis.

Gold Electroplating & Electroless Deposition

Provides Au(III) ions for electrolytic and autocatalytic gold plating baths, delivering bright, ductile, corrosion-resistant coatings on electronics, connectors, and jewelry.

Supported Gold Catalyst Preparation

Used in impregnation or deposition to create Au on carbon, alumina, or oxide supports for selective oxidation, hydrogenation, and CO removal in fine chemicals and emission control.

Thin-Film & Seed Layer Deposition

Enables solution-based gold film formation for microelectronics, sensors, and plasmonic devices requiring high-purity and controlled thickness.

Organometallic Gold Complex Synthesis

Acts as precursor for preparing Au(III) and reduced Au(I) complexes with phosphines, carbenes, or other ligands in catalysis and materials research.

Advanced Materials & Nanotechnology

Facilitates gold nanoshell, nanorod, or composite synthesis for photothermal therapy, SERS substrates, and functional coatings.

Why Choose Aure Chemical for Your Chloroauric Acid Hydrate Supply?

Partner with Aure Chemical for Chloroauric Acid Hydrate to access premium gold reactivity, technical expertise, and stable precious metal supply for your gold-based applications.

Precise Gold Content & Purity

Advanced quality controls ensure accurate Au assay, minimal impurities, and batch reproducibility for reliable reduction or deposition performance.

Secure Precious Metal Sourcing

Transparent, responsible gold procurement with inventory buffering to provide supply stability and competitive pricing.

Technical Application Support

Dedicated specialists offer guidance on reduction protocols, nanoparticle stabilization, plating bath formulation, and process optimization.

Comprehensive Regulatory Compliance

Full COA, REACH, RoHS, and detailed SDS documentation to facilitate seamless integration into global operations.

Sustainability & Recycling Commitment

Ethical sourcing practices and gold recovery/recycling programs aligned with ESG objectives and circular economy principles.

Hazards Classification

GHS Classification: Skin Corrosion (Category 1A); Serious Eye Damage (Category 1); Acute Toxicity, Oral (Category 3); Acute Toxicity, Inhalation (Category 3); Aquatic Chronic (Category 1)

Hazard Statements: H314: Causes severe skin burns and eye damage; H301 + H331: Toxic if swallowed or if inhaled; H410: Very toxic to aquatic life with long lasting effects

UN Number: UN 3260

Hazard Class: 8 (Corrosive substances)

Packing Group: III

GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity GHS09: Environment (aquatic toxicity)

GHS09: Environment (aquatic toxicity)