Explore Top-Quality Thiourea Dioxide with Aure Chemical

Aure Chemical is a premier global supplier of high-quality Thiourea Dioxide ($CH_4N_2O_2S$), widely recognized by its abbreviation TDO or its systematic name Formamidinesulfinic Acid (FAS). Identified by its CAS number 1758-73-2, this organosulfur compound is a white, odorless crystalline powder. Thiourea Dioxide stands out as a highly effective and versatile reducing and bleaching agent, offering a more environmentally friendly alternative to traditional reducing agents like sodium dithionite. Its non-toxic nature, excellent stability, and strong reductive capabilities make it an indispensable chemical in various industrial applications, particularly in the textile, paper, and wastewater treatment sectors. Aure Chemical's unwavering commitment to excellence ensures that our Thiourea Dioxide meets the stringent purity and performance requirements for your most demanding processes, guaranteeing consistency and reliability.

Basic Information of Thiourea Dioxide

Thiourea Dioxide (CAS No. 1758-73-2) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 1758-73-2 |

|---|

| EC No.: | 217-157-8 |

|---|

| Linear Formula: | CH₄N₂O₂S |

|---|

| Molecular Weight: | 108.12 |

|---|

| Appearance: | White crystalline powder |

|---|

| Melting Point: | 124-127 °C (dec.)(lit.) |

|---|

| Boiling Point: | 355.3±25.0 °C(Predicted) |

|---|

| Density: | 1.68 |

|---|

| Solubility: | Moderately soluble in water; sparingly soluble in alcohol. |

|---|

| Reducing Power: | Exhibits strong reducing power, particularly in alkaline solutions. |

|---|

| Stability: | Relatively stable in dry form. More stable than sodium dithionite in solution. |

|---|

| Environmental Profile: | Biodegradable and less polluting compared to sulfur-containing reducing agents, as it primarily decomposes into urea, sulfate, and carbon dioxide. |

|---|

| RIDADR: | UN 3341 4.2/PG 2 |

|---|

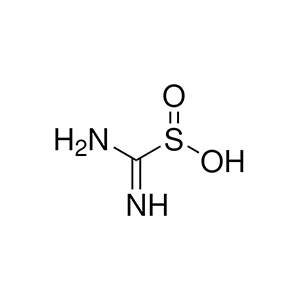

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Thiourea Dioxide ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse industrial needs.

Primary Applications of Thiourea Dioxide (TDO)

Thiourea Dioxide's powerful reducing and bleaching capabilities, coupled with its favorable environmental profile, make it an incredibly valuable compound with applications across several industries:

Textile Industry:

It is widely used as a reducing agent in vat dyeing and sulfur dyeing processes, helping to dissolve insoluble dyes and fix them onto fibers. It also serves as a highly effective bleaching agent for wool, silk, and other natural and synthetic fibers, improving whiteness without damaging the fabric. Furthermore, it acts as a desizing agent to remove sizing from fabrics.

Paper Industry:

TDO is a key chemical for deinking waste paper, effectively removing printing inks from recycled pulp to produce brighter, higher-quality recycled paper. It also functions as a bleaching agent for pulp, improving paper whiteness.

Wastewater Treatment:

It is increasingly used in wastewater treatment as a reducing agent to remove heavy metal ions (e.g., chromium, copper), dyes, and other pollutants from industrial effluents. Its ability to reduce hexavalent chromium to trivalent chromium is particularly important for environmental protection.

Chemical Synthesis:

TDO serves as a selective reducing agent in various organic synthesis reactions, particularly in the production of pharmaceuticals, fine chemicals, and agrochemicals where precise reduction is required.

Photography:

In some photographic processes, Thiourea Dioxide can be used as a component in certain developing or toning solutions.

Why Choose Aure Chemical for Your Thiourea Dioxide Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Thiourea Dioxide requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Thiourea Dioxide is manufactured to stringent purity specifications, ensuring its maximum effectiveness as a reducing and bleaching agent in your processes. We guarantee consistent performance batch after batch.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all strict safety and regulatory standards.

Eco-Friendly Solution: By choosing Aure Chemical's Thiourea Dioxide, you opt for a more sustainable and environmentally responsible chemical, aligning with modern industrial practices and environmental regulations.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Thiourea Dioxide.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Thiourea Dioxide. We're ready to support your most demanding and innovative industrial processes.

Hazards Classification

GHS Classification: Acute Toxicity (GHS06), Skin Corrosion/Irritation (GHS07), Self-Reactive Substances (GHS01)

Hazard Statements: Harmful if swallowed; causes skin irritation and serious eye irritation; may cause fire or explosion, strong reducing agent.

UN Number: UN 3341

Hazard Class: 4.2 (Spontaneously Combustible)

Packing Group: II

GHS01: Explosive

GHS01: Explosive GHS06: Acute toxicity

GHS06: Acute toxicity GHS07: Irritant

GHS07: Irritant