High-Purity Ruthenium Nitrosyl Nitrate Solution from Aure Chemical – Your Trusted Source

Ruthenium nitrosyl nitrate solution, Ru(NO)(NO₃)₃ in aqueous form, CAS No. 34513-98-9, is a convenient, water-soluble ruthenium nitrosyl precursor widely used in catalysis and materials processing. Supplied by Aure Chemical as a dark red to brown liquid with ruthenium concentrations typically ranging from 5–20% Ru (w/w), this stabilized solution provides an efficient source of Ru nitrosyl species for preparing supported ruthenium catalysts, synthesizing nitrosyl-containing organometallic complexes, and depositing ruthenium-based thin films or coatings via solution-based techniques. Its unique nitrosyl ligand imparts distinct electronic properties, making it valuable for oxidation catalysis, electrocatalysis, and functional material development in fine chemicals, energy, and electronics applications. The nitrate-based formulation eliminates chloride contamination risks, ideal for high-purity processes. Aure Chemical offers precise Ru content control, low impurity profiles, and secure ruthenium sourcing to ensure reproducible results in industrial and laboratory settings worldwide.

Basic Information of Ruthenium Nitrosyl Nitrate Solution

Aure Chemical delivers Ruthenium Nitrosyl Nitrate Solution as a high-quality aqueous Ru nitrosyl precursor optimized for deposition, impregnation, and synthesis, available in commercial Ru concentrations with verified composition.

| CAS No. | 34513-98-9 |

|---|

| EC No. | 252-065-8 |

|---|

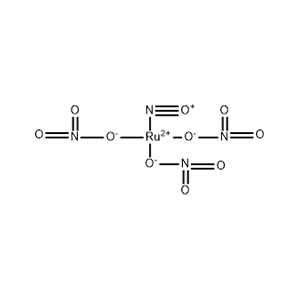

| Chemical Formula | Ru(NO)(NO₃)₃ (aq.) |

|---|

| Molecular Weight | 317.07 g/mol (anhydrous basis) |

|---|

| Appearance | Dark red to brown liquid (aqueous solution, typically 5–20% Ru w/w) |

|---|

| Odor | Odorless to slight nitric |

|---|

| Melting point | Not applicable (liquid solution) |

|---|

| Boiling point | >100 °C (water-based; decomposes on heating) |

|---|

| Density | 1.05–1.40 g/mL at 25 °C (concentration-dependent) |

|---|

| Solubility | Miscible with water; soluble in alcohols, acetone |

|---|

| Nature (hazards) | Corrosive to metals and skin, causes severe skin burns and eye damage, respiratory and skin sensitizer, toxic to aquatic life |

|---|

| RIDADR | UN 3264, Corrosive liquid, acidic, inorganic, n.o.s. (Ruthenium nitrosyl nitrate solution), Class 8, Packing Group III |

|---|

| Chemical Structure |  |

|---|

Aure Chemical offers customizable Ru concentrations (e.g., 5%, 10%, 15%, 20% Ru w/w), adjusted acidity or nitrate levels, and specialized packaging to align with your deposition, catalyst, or synthesis process needs.

Primary Applications of Ruthenium Nitrosyl Nitrate Solution

Ruthenium Nitrosyl Nitrate Solution provides a clean, ready-to-use Ru nitrosyl source for solution processing, enabling precise ruthenium incorporation in high-technology and catalytic applications.

Supported Ruthenium Catalyst Impregnation

Used in wet impregnation of carbon, alumina, silica, or other supports to create high-dispersion Ru catalysts for hydrogenation, ammonia synthesis, and Fischer-Tropsch processes.

Thin-Film & Coating Deposition

Serves as a solution-based Ru source for spin-coating, dip-coating, or electrodeposition of ruthenium or ruthenium oxide films in microelectronics, sensors, and catalytic coatings.

Organometallic Ruthenium Complex Synthesis

Acts as a nitrosyl-containing Ru precursor for preparing mixed-ligand Ru complexes in homogeneous catalysis and materials research.

Electrocatalyst Development for Energy Applications

Enables synthesis of Ru-based electrocatalysts for oxygen evolution reaction (OER), hydrogen evolution, and alcohol oxidation in electrolyzers and fuel cells.

Advanced Materials & Nanotechnology

Facilitates controlled reduction to generate ruthenium nanostructures, functional coatings, or supported clusters requiring high purity and controlled Ru loading.

Fine Chemical & Oxidation Catalysis

Supports preparation of Ru catalysts for selective oxidation and dehydrogenation reactions in specialty chemical production.

Why Choose Aure Chemical for Your Ruthenium Nitrosyl Nitrate Solution Supply?

Trust Aure Chemical for Ruthenium Nitrosyl Nitrate Solution, combining premium quality, flexible customization, and expert precious metal support for your advanced ruthenium applications.

Accurate & Consistent Ru Concentration

Precise analytical control ensures uniform ruthenium content, low impurities, and batch reproducibility for reliable deposition or catalytic performance.

Stabilized Aqueous Formulation

Optimized stability in water minimizes decomposition and hazards while maintaining full precursor reactivity and versatility.

Custom Solution Tailoring

Adjustable Ru levels, concentration ranges, and minor additives to perfectly match your specific process or formulation requirements.

Technical Process Support

Dedicated specialists provide advice on solution handling, catalyst activation, deposition techniques, and optimization for maximum efficiency.

Regulatory & Sustainability Focus

Full COA, REACH, RoHS, SDS documentation and ruthenium recycling programs to support global compliance and your ESG commitments.

Hazards Classification

GHS Classification: Skin Corrosion/Irritation (Category 1B); Serious Eye Damage (Category 1); Skin Sensitization (Category 1); Acute Toxicity, Oral (Category 4); Aquatic Chronic (Category 2)

Hazard Statements: H314: Causes severe skin burns and eye damage; H317: May cause an allergic skin reaction; H302: Harmful if swallowed; H411: Toxic to aquatic life with long lasting effects

UN Number: UN 3264

Hazard Class: 8 (Corrosive substances)

Packing Group: III

GHS05: Corrosive

GHS05: Corrosive GHS07: Exclamation mark (sensitizer, acute toxicity)

GHS07: Exclamation mark (sensitizer, acute toxicity) GHS09: Environment (aquatic toxicity)

GHS09: Environment (aquatic toxicity)