Discover Aure Chemical's Premium Methanol Supply

Aure Chemical is a leading global supplier of high-quality Methanol, also widely known as Methyl Alcohol or historically as Wood Alcohol. This fundamental chemical is one of the most versatile and widely used organic building blocks globally, serving as a critical feedstock and solvent across numerous industries. We are committed to delivering Methanol with exceptional purity and a consistent, reliable supply chain.

Basic Information of Methanol

Methanol (CAS No. 67-56-1) is the simplest alcohol, a cornerstone of the chemical industry. Its unique chemical properties make it an indispensable compound, from energy applications to the production of a vast array of everyday materials.

| CAS No.: | 67-56-1 |

|---|

| EC No.: | 200-659-6 |

|---|

| Linear Formula: | CH₄O |

|---|

| Molecular Weight: | 32.04 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Melting Point: | -98 °C(lit.) |

|---|

| Boiling point | 65.4 °C(lit.) |

|---|

| Density: | 0.791 g/mL at 25 °C |

|---|

| RIDADR: | UN 1230 3/PG 2 |

|---|

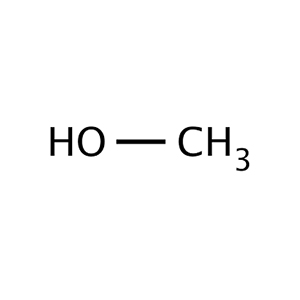

| Chemical Structure: |  |

|---|

Key Applications of Methanol (Methyl Alcohol)

Methanol's reactivity and properties make it an invaluable compound across diverse sectors:

Formaldehyde Production: The largest single use of methanol is in the production of formaldehyde, which is then used to make resins (like urea-formaldehyde, melamine-formaldehyde, and phenol-formaldehyde) for adhesives, plastics, and coatings.

Methanol to Olefins/Propylene (MTO/MTP): A growing application where methanol is converted into light olefins such as ethylene and propylene, which are fundamental building blocks for plastics.

Fuels and Energy: Methanol is gaining importance as a clean-burning fuel or fuel additive (e.g., in marine fuel, biodiesel, and as a component in gasoline blending). It's also used to produce MTBE (Methyl Tert-Butyl Ether), an octane enhancer (though its use is declining in some regions).

Solvent: Its excellent solvency makes it a widely used solvent in various industrial processes, including paint strippers, cleaning solutions, and chemical reactions.

Chemical Intermediate: A crucial feedstock for the production of numerous other chemicals, including acetic acid, methyl tertiary-butyl ether (MTBE), methyl methacrylate (MMA), and various methylamines.

Antifreeze: Used in some antifreeze formulations for vehicles and pipelines.

Aure Chemical: Your Reliable Methanol Partner

Partnering with Aure Chemical for your Methanol supply means benefiting from:

High Purity and Consistent Quality: Ensuring optimal performance and yield in your chemical processes.

Robust Global Supply Chain: Our extensive logistics network guarantees efficient and secure supply in bulk of Methanol to your facilities worldwide.

Commitment to Safety & Compliance: We adhere to the highest safety standards for the handling, storage, and transportation of this highly flammable and toxic liquid, providing comprehensive Safety Data Sheets (SDS) and necessary dangerous goods documentation.

Dedicated Customer Support: Our knowledgeable team is always available to provide technical insights and assist with your ordering and logistical requirements.

Large-Volume Capabilities: We can meet your extensive methanol demands with reliable and timely deliveries.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Acute Toxicity (GHS06), Health Hazard (GHS08)

Hazard Statements: Highly flammable liquid and vapor; fatal if swallowed, in contact with skin, or if inhaled; causes damage to organs (optic nerve, liver, kidney); may cause drowsiness or dizziness.

UN Number: UN 1230

Hazard Class: 3 (Flammable Liquids)

Packing Group: II

GHS02: Flammable

GHS02: Flammable GHS06: Acute toxicity

GHS06: Acute toxicity GHS08: Health hazard

GHS08: Health hazard