Discover Aure Chemical's Premium Hexafluoropropylene (HFP) Supply

Aure Chemical is a leading global supplier of Hexafluoropropylene (HFP), also known as Hexafluoropropene or Perfluoropropene. This essential fluorinated alkene is a critical building block for high-performance fluoropolymers and a key intermediate in the synthesis of advanced specialty chemicals. We are committed to delivering high-purity HFP with consistent quality and a reliable supply chain.

Basic Information of Hexafluoropropylene

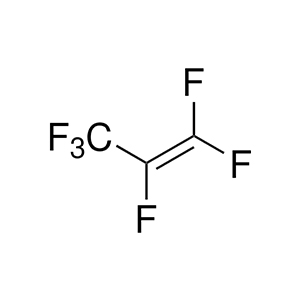

Hexafluoropropylene (CAS No. 116-15-4) is a colorless, non-flammable gas at room temperature, which can be liquefied under pressure. Its unique molecular structure, containing six fluorine atoms and a double bond, imparts exceptional thermal, chemical, and electrical stability to the materials derived from it, making it indispensable for demanding applications.

| CAS No.: | 116-15-4 |

|---|

| EC No.: | 204-127-4 |

|---|

| Linear Formula: | C₃F₆ |

|---|

| Molecular Weight: | 150.02 |

|---|

| Appearance: | colorless, non-flammable gas |

|---|

| Melting Point: | −153 °C(lit.) |

|---|

| Boiling point | −28 °C(lit.) |

|---|

| Density: | 1,583 g/cm3 |

|---|

| RIDADR: | UN 1858 2.2 |

|---|

| Chemical Structure: |  |

|---|

Key Applications of Hexafluoropropylene (HFP)

HFP's unique properties make it an invaluable monomer and intermediate across various high-tech industries:

Fluoropolymer Production (Copolymers): The primary application. HFP is a key comonomer with tetrafluoroethylene (TFE) to produce:

Fluorocarbon Elastomers (FKM): High-performance synthetic rubbers with excellent resistance to heat, chemicals, oils, and fuels, used in automotive, aerospace, and chemical processing industries.

Perfluoroalkoxy Alkanes (PFA): A melt-processible fluoropolymer with superior chemical resistance and high-temperature performance, used in linings, tubing, and wire insulation.

Fluorinated Ethylene Propylene (FEP): Another melt-processible fluoropolymer known for its excellent chemical resistance, non-stick properties, and optical clarity, used in wiring, tubing, and non-stick coatings.

Fluorinated Intermediate: Serves as a versatile building block for the synthesis of various fluorinated specialty chemicals, including fluorinated oils, lubricants, surfactants, and fire extinguishants.

Refrigerant Precursor: Used in the production of certain hydrofluorocarbon (HFC) and hydrofluoroolefin (HFO) refrigerants.

Aure Chemical: Your Reliable HFP Partner

Partnering with Aure Chemical for your Hexafluoropropylene supply means benefiting from:

Uncompromising Quality & Purity: We ensure ultra-high purity and consistent specifications essential for your high-value applications.

Robust Global Logistics: Our extensive network guarantees efficient and secure supply in bulk of HFP to your facilities worldwide, in full compliance with international dangerous goods regulations for compressed/liquefied gases.

Commitment to Safety & Compliance: We adhere to the highest safety standards for the handling, storage, and transportation of this pressurized gas, providing complete Safety Data Sheets (SDS) and necessary dangerous goods documentation.

Dedicated Customer Support: Our knowledgeable team is always available to provide technical insights and assist with your ordering and logistical requirements.

Strategic Partnerships: We aim to build long-term relationships, providing a consistent and optimized supply to meet your continuous production needs.

Hazards Classification

GHS Classification: Gas Under Pressure (GHS04), Health Hazard (GHS08)

Hazard Statements: Contains gas under pressure; may explode if heated; may cause damage to organs through prolonged or repeated exposure; may displace oxygen and cause rapid suffocation.

UN Number: UN 2191

Hazard Class: 2.1 (Flammable Gas)

Packing Group: Not applicable

GHS04: Gas under pressure

GHS04: Gas under pressure GHS08: Health hazard

GHS08: Health hazard