Aure Chemical: Your Reliable Source for High-Purity Fluoroboric Acid

Aure Chemical is a premier global supplier of high-quality Fluoroboric Acid (HBF₄), widely known as Tetrafluoroboric Acid or Hydrofluoroboric Acid. Identified by its CAS number 16872-11-0, this inorganic acid is typically supplied as a colorless to light yellow aqueous solution. Fluoroboric Acid is a strong, non-oxidizing acid that is highly stable and does not attack glass or most common metals at room temperature, unlike hydrofluoric acid. These unique properties make it an indispensable asset in numerous industrial applications, particularly in metal finishing, where it is a cornerstone of advanced electroplating processes (especially for bright tin and lead-tin alloys), and as a versatile catalyst in organic synthesis. Aure Chemical's unwavering commitment to excellence ensures that our Fluoroboric Acid meets the stringent purity and concentration requirements for your most demanding industrial and specialty chemical applications, guaranteeing consistency, safety, and superior performance.

Basic Information of Fluoroboric Acid

Fluoroboric Acid (CAS No. 16872-11-0) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent concentration, essential for your critical applications:

| CAS No.: | 16872-11-0 |

|---|

| EC No.: | 240-898-3 |

|---|

| Linear Formula: | HBF₄ |

|---|

| Molecular Weight: | 87.81 |

|---|

| Appearance: | Clear, colorless to pale yellow aqueous solution. |

|---|

| Concentration: | Typically available in various concentrations, commonly 48-50% (w/w) |

|---|

| Acidity: | Strong inorganic acid. |

|---|

| Boiling Point: | 130°C (dec.) |

|---|

| Density: | 1.38 g/mL at 20 °C(lit |

|---|

| Solubility: | Highly soluble and miscible with water. |

|---|

| Flash Point: | −40 ° |

|---|

| Non-oxidizing: | Does not readily oxidize other substances. |

|---|

| Stability: | Stable in aqueous solution. Does not attack glass or quartz. |

|---|

| Corrosivity: | Corrosive to skin, eyes, and mucous membranes. Less corrosive to certain metals than other strong acids. |

|---|

| RIDADR: | UN 1775 8/PG 2 |

|---|

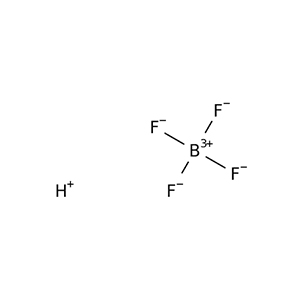

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Fluoroboric Acid ensures a reliable and efficient component for your critical processes, offering consistent quality for diverse industrial needs.

Primary Applications of Fluoroboric Acid

Fluoroboric Acid's properties as a strong, stable, and non-oxidizing acid, along with its ability to form stable complexes, make it a fundamental chemical with extensive applications across various industries:

Electroplating & Metal Finishing:

Fluoroboric Acid is a crucial component in electroplating baths, particularly for depositing bright, high-speed coatings of tin, lead-tin alloys, nickel, copper, and precious metals. It ensures uniform deposits, improved adhesion, and superior finish quality. It is also used in metal cleaning and pickling operations.

Catalyst in Organic Synthesis:

It serves as a versatile acid catalyst in various organic synthesis reactions, including polymerization, alkylation, and acylation reactions. Its stability and strong acidity make it effective in specific chemical transformations.

Production of Fluoroborate Salts:

Fluoroboric Acid is the primary precursor for manufacturing a wide range of fluoroborate salts (e.g., potassium fluoroborate, sodium fluoroborate, zinc fluoroborate). These salts find applications in fluxes for brazing and welding, flame retardants, and as components in various industrial processes.

Anodizing Aluminum:

It is used in certain anodizing processes for aluminum, providing a uniform and durable oxide layer that enhances corrosion resistance and appearance.

Analytical Reagent:

In laboratories, it is used as a reagent for specific chemical analyses and preparations, particularly where a strong, non-oxidizing acid containing fluoride is required.

Why Choose Aure Chemical for Your Fluoroboric Acid Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Fluoroboric Acid requirements, you benefit from:

Exceptional Purity & Consistent Quality: Our Fluoroboric Acid is manufactured to stringent purity and concentration specifications, crucial for optimizing performance in sensitive applications like high-quality electroplating and catalyst formulations.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential acid to your facilities worldwide, adhering to all strict safety and regulatory standards for corrosive materials.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Fluoroboric Acid, emphasizing safety protocols due to its corrosive nature.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Fluoroboric Acid. We're ready to support your most demanding and innovative industrial processes.

Hazards Classification

GHS Classification: Corrosive (GHS05), Acute Toxicity (GHS06)

Hazard Statements: Causes severe skin burns and eye damage; toxic if swallowed or inhaled.

UN Number: UN 1775

Hazard Class: 8 (Corrosive Substances)

Packing Group: II

GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity