Explore Top-Quality Dimethyl Phosphite (CAS 868-85-9) with Aure Chemical

Aure Chemical is a premier global supplier of high-quality Dimethyl Phosphite ((CH₃O)₂P(O)H), commonly abbreviated as DMP. Identified by its CAS number 868-85-9, this organophosphorus compound is a clear, colorless liquid with a characteristic odor. Dimethyl Phosphite is a highly versatile and reactive chemical, widely recognized for its dual nature as both a potent reducing agent and a crucial intermediate in various synthetic pathways. It plays a pivotal role in the production of a wide range of phosphonates, agrochemicals (like pesticides), pharmaceuticals, and polymer additives. Aure Chemical's unwavering commitment to excellence ensures that our Dimethyl Phosphite meets the stringent purity and performance requirements for your most demanding industrial and research applications, guaranteeing consistency and reliability.

Basic Information of Dimethyl Phosphite

Dimethyl Phosphite (CAS No. 868-85-9) is meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your complex chemical processes:

| CAS No.: | 868-85-9 |

|---|

| EC No.: | 212-783-8 |

|---|

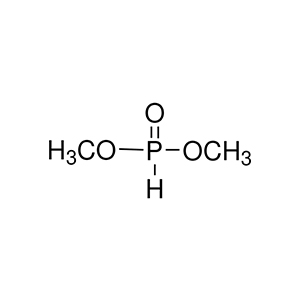

| Linear Formula: | (CH₃O)₂P(O)H |

|---|

| Molecular Weight: | 110.05 |

|---|

| Appearance: | Transparent Liquid |

|---|

| Boiling point: | 170-171 °C(lit.) |

|---|

| Density: | 1.2 g/mL at 25 °C(lit.) |

|---|

| Solubility: | Soluble in many organic solvents such as alcohols, ethers, and benzene. Reacts slowly with water to hydrolyze. |

|---|

| Flash point | 71 °C |

|---|

| Nature: | Exhibits tautomerism between phosphite and phosphonate forms. Acts as a reducing agent and a nucleophile. |

|---|

| RIDADR: | UN 3278 6.1/PG 3 |

|---|

| Chemical Structure: |  |

|---|

Our commitment to delivering high-purity Dimethyl Phosphite ensures a reliable and efficient component for your critical chemical syntheses, offering consistent quality for diverse industrial needs.

Primary Applications of Dimethyl Phosphite

Dimethyl Phosphite's unique reactivity and versatility make it an indispensable compound with applications across numerous industries:

Chemical Intermediate:

It is a fundamental building block in the synthesis of a wide array of organic compounds, particularly in the production of phosphonates. These derivatives are crucial for various applications, including water treatment chemicals, metal complexing agents, and flame retardants.

Horner-Wadsworth-Emmons (HWE) Reaction:

It is a key starting material for generating phosphonate carbanions used in the Horner-Wadsworth-Emmons reaction. This reaction is highly valuable in organic synthesis for the stereoselective formation of carbon-carbon double bonds (olefins) from aldehydes and ketones.

Arbuzov Reaction:

Dimethyl Phosphite readily participates in the Arbuzov reaction with alkyl halides to form phosphonates, which are versatile intermediates in different chemical syntheses.

Reducing Agent:

Due to the presence of a P-H bond, it acts as a mild yet effective reducing agent in various chemical transformations, offering controlled reduction in specific synthetic routes.

Pesticide and Agrochemical Synthesis:

It is used in the manufacturing of various pesticides and agrochemicals, particularly those with organophosphorus structures, contributing to crop protection and agricultural efficiency.

Pharmaceutical Intermediates:

Dimethyl Phosphite is utilized in the synthesis of certain pharmaceutical intermediates and active pharmaceutical ingredients (APIs), enabling the creation of complex drug molecules.

Polymer Additives:

It finds application as an antioxidant and stabilizer in certain polymer formulations, improving their performance and extending their lifespan.

Why Choose Aure Chemical for Your Dimethyl Phosphite Supply?

Aure Chemical is dedicated to providing superior chemical solutions and unparalleled customer support. By partnering with us for your Dimethyl Phosphite requirements, you benefit from:

Exceptional Purity & Reactivity: Our Dimethyl Phosphite is manufactured to stringent purity specifications, crucial for ensuring high yields and clean reactions in complex organic syntheses and industrial processes.

Reliable Global Supply Chain: We maintain a robust and efficient supply network, guaranteeing timely and secure delivery of this essential chemical to your facilities worldwide, adhering to all strict safety and regulatory standards.

Expert Technical Support: Our team of experienced chemists and specialists is readily available to offer comprehensive guidance on product application, safe handling procedures, and optimal storage conditions for Dimethyl Phosphite.

Commitment to Quality & Safety: We adhere to the highest industry standards for quality management, safety, and environmental responsibility across all our operations, ensuring peace of mind for our clients.

Choose Aure Chemical for a trustworthy and dependable supply of high-quality Dimethyl Phosphite. We're ready to support your most demanding and innovative industrial processes.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Acute Toxicity (GHS06), Health Hazard (GHS08)

Hazard Statements: Flammable liquid and vapor; harmful if swallowed or in contact with skin; suspected of causing cancer.

UN Number: UN 3278

Hazard Class: 6.1 (Flammable Liquids)

Packing Group: III

GHS02: Flammable

GHS02: Flammable GHS06: Acute toxicity

GHS06: Acute toxicity GHS08: Health hazard

GHS08: Health hazard