High-Purity Chloroplatinic Acid Solution from Aure Chemical – Your Trusted Source

Chloroplatinic acid solution, also known as hexachloroplatinic(IV) acid or dihydrogen hexachloroplatinate(IV) solution, CAS No. 16941-12-1, is a critical aqueous platinum(IV) source widely used in precious metal applications. Supplied by Aure Chemical as a clear to reddish-orange liquid with platinum concentrations typically ranging from 8–25% Pt (w/w), this stable solution offers high platinum solubility and serves as an efficient precursor for preparing hydrosilylation catalysts, supported heterogeneous catalysts, electroplating baths, and various platinum compounds. Its convenience in liquid form reduces handling risks compared to solids while maintaining excellent reactivity and purity for catalyst manufacturing, silicone curing systems, surface coatings, and inorganic syntheses in catalysis, electronics, and fine chemicals. Aure Chemical provides precise Pt content control, low impurity profiles, and secure supply to ensure reproducible results in industrial and R&D processes.

Basic Information of Chloroplatinic Acid Solution

Aure Chemical delivers Chloroplatinic Acid Solution as a high-quality aqueous platinum(IV) precursor optimized for catalyst preparation and metal deposition, available in commercial Pt concentrations with verified composition.

| CAS No. | 16941-12-1 |

|---|

| EC No. | 241-010-7 |

|---|

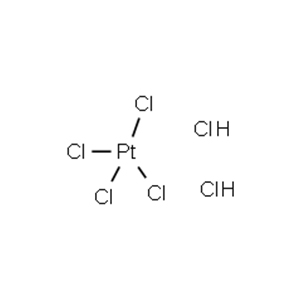

| Chemical Formula | H2PtCl6 (aq.) |

|---|

| Molecular Weight | 409.81 g/mol (anhydrous basis) |

|---|

| Appearance | Clear to reddish-orange liquid (aqueous solution, typically 8–25% Pt w/w) |

|---|

| Odor | Odorless |

|---|

| Melting point | Not applicable (liquid solution) |

|---|

| Boiling point | >100 °C (water-based; decomposes on heating) |

|---|

| Density | 1.05–1.30 g/mL at 25 °C (concentration-dependent) |

|---|

| Solubility | Miscible with water; soluble in alcohols and acetone |

|---|

| Nature (hazards) | Corrosive to metals and skin, causes severe skin burns and eye damage, respiratory and skin sensitizer, toxic to aquatic life |

|---|

| RIDADR | UN 3264, Corrosive liquid, acidic, inorganic, n.o.s. (Hexachloroplatinic acid solution), Class 8, Packing Group III |

|---|

| Chemical Structure |  |

|---|

Aure Chemical offers customizable concentrations (e.g., 8%, 20%, 25% Pt w/w), adjusted pH or chloride levels, and specialized packaging to meet your specific catalyst synthesis, plating, or process requirements.

Primary Applications of Chloroplatinic Acid Solution

Chloroplatinic Acid Solution functions as a convenient, high-platinum-content precursor for diverse platinum-based technologies and syntheses across multiple sectors.

Hydrosilylation Catalyst Preparation

Serves as the primary starting material for producing Karstedt's catalyst, Speier's catalyst, and other Pt-based hydrosilylation catalysts essential for silicone crosslinking and organosilicon manufacturing.

Supported Heterogeneous Catalysts

Used in impregnation or deposition processes to prepare Pt on carbon, alumina, or silica supports for hydrogenation, dehydrogenation, and oxidation in petrochemical and fine chemical catalysis.

Electroplating Baths

Provides platinum ions for electrolytic deposition of hard, corrosion-resistant Pt layers on electrical contacts, medical instruments, and decorative finishes requiring low contact resistance.

Platinum Compound Synthesis

Acts as feedstock for preparing organometallic Pt complexes, cisplatin analogs, and other coordination compounds in pharmaceutical research and anticancer agent development.

Conductive Coatings and Electronics

Enables formation of platinum seed layers or conductive films in electronics, sensors, fuel cells, and specialty glass applications demanding high durability and conductivity.

Chemical and Materials Research

Facilitates synthesis of Pt nanoparticles, colloids, and functional materials for advanced catalysis, electrocatalysis, and nanomaterial studies in academic and industrial labs.

Why Choose Aure Chemical for Your Chloroplatinic Acid Solution Supply?

Trust Aure Chemical for Chloroplatinic Acid Solution, combining premium purity, flexible customization, and expert precious metal support for your critical platinum applications.

Accurate Platinum Concentration

Precise gravimetric and analytical verification ensures consistent Pt content and low impurities for reliable downstream catalyst or coating performance.

Custom Solution Formulations

Tailored Pt percentages, concentration ranges, and minor additives to align perfectly with your synthesis, plating bath, or process specifications.

Stable Precious Metal Supply

Responsible sourcing and strategic platinum inventory management deliver uninterrupted availability and pricing predictability.

Technical Expertise

Dedicated specialists provide guidance on precursor use, catalyst preparation, plating optimization, and troubleshooting for enhanced process efficiency.

Regulatory Compliance & Sustainability

Full documentation (COA, REACH, SDS) and platinum recycling/recovery programs support global compliance and your environmental responsibility goals.

Hazards Classification

GHS Classification: Acute Toxicity, Oral (Category 3 or 4 depending on concentration); Skin Corrosion (Category 1B); Serious Eye Damage (Category 1); Respiratory Sensitization (Category 1); Skin Sensitization (Category 1); Aquatic Acute/Chronic (Category 1 or 2)

Hazard Statements: H301 or H302: Toxic or harmful if swallowed; H314: Causes severe skin burns and eye damage; H317: May cause an allergic skin reaction; H334: May cause allergy or asthma symptoms or breathing difficulties if inhaled; H410: Very toxic to aquatic life with long lasting effects

UN Number: UN 3264

Hazard Class: 8 (Corrosive substances)

Packing Group: III

GHS05: Corrosive

GHS05: Corrosive GHS06: Acute toxicity

GHS06: Acute toxicity GHS07: Exclamation mark (sensitizer)

GHS07: Exclamation mark (sensitizer) GHS09: Environment (aquatic toxicity)

GHS09: Environment (aquatic toxicity)