Explore Top-Quality Diisobutyl Ketone with Aure Chemical

Diisobutyl Ketone (DIBK), CAS 108-83-8, is a colorless, stable, and high-purity solvent characterized by its slow evaporation rate and high solvency power. It possesses a mild, slightly sweet, and characteristic oily ketone odor. DIBK is a high-boiling ketone, making it an essential component in coatings and inks where a prolonged flow time and blush resistance are required. Its strong dissolving capability for a wide range of natural and synthetic resins, particularly nitrocellulose and vinyl polymers, makes it a premium industrial solvent.

Basic Information of DIBK

Meticulously produced and rigorously tested to meet stringent quality standards. We ensure exceptional purity and consistent performance, essential for your critical applications:

| CAS No.: | 108-83-8 |

|---|

| EC No.: | 203-620-1 |

|---|

| Linear Formula: | C9H18O |

|---|

| Molecular Weight: | 142.24 |

|---|

| Appearance: | Colorless, clear liquid |

|---|

| Odor: | Mild, sweet, oily ketone odor |

|---|

| Melting Point: | -46 °C |

|---|

| Boiling Point: | 165-170 °C(lit.) |

|---|

| Density: | 0.808 g/mL at 25 °C(lit.) |

|---|

| Solubility: | Very slightly soluble in water; miscible with most organic solvents. |

|---|

| Flash Point: | 120 °F |

|---|

| RIDADR: | UN 1157 3/PG 3 |

|---|

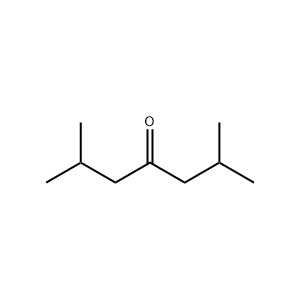

| Chemical Structure: |  |

|---|

Application Overview

DIBK's slow evaporation rate and powerful solvency profile make it highly desirable for industrial processes requiring controlled drying and high resin load capacity:

Automotive and Industrial Coatings: It is widely used in high-performance automotive finishes, coil coatings, and specialized protective paints. Its slow evaporation rate prevents bubbles and "blushing" (whitening) in the film, ensuring a smooth, glossy, and high-quality finish.

Printing Inks: Used as a solvent for high-speed printing inks, particularly those based on vinyl and polyurethane resins. DIBK controls the viscosity and ensures proper flow and adherence to the substrate.

Extraction Solvent: Due to its limited miscibility with water, DIBK is an effective liquid-liquid extraction solvent used in various chemical processes, including the purification of antibiotics, hormones, and other high-value organic compounds.

Cleaning and Degreasing: Employed as a high-strength solvent for industrial cleaning and degreasing of process equipment, particularly for removing highly polymerized resins and tough residues.

Adhesives and Sealants: It acts as a solvent in the formulation of various adhesives and cementing compounds, offering controlled drying and superior dissolving power for polymer bases.

Why Choose Aure Chemical for DIBK?

Aure Chemical offers Diisobutyl Ketone (CAS 108-83-8) with a focus on maximizing purity, optimizing stability, and delivering comprehensive technical support for high-specification industrial use.

Superior Isomer Purity: We utilize an optimized synthesis route that yields high purity DIBK, with rigorous control over the main isomer. This consistency ensures predictable, repeatable performance in complex coating and ink formulations, preventing unexpected changes in drying time or film quality.

Certified Low Non-Volatile Residue (NVR): Our DIBK is guaranteed to have near-zero NVR, verified by stringent internal quality protocols. This makes it ideal for highly sensitive applications, such as electronics, precision cleaning, and pharmaceutical extraction, where any residue is detrimental.

Customized Evaporation Data: Beyond standard property data, we provide customers with tailored relative evaporation rate data (e.g., relative to Butyl Acetate) under specific conditions. This assists formulators in precisely adjusting solvent blends to meet client specifications for drying profiles.

Advanced Quality Management: Aure Chemical employs a comprehensive Quality Management System (QMS) that tracks the product from raw material to delivery, including batch-specific GC analysis and a full Certificate of Analysis (CoA) with every shipment, ensuring total compliance and trust.

Hazards Classification

GHS Classification: Flammable Liquid (GHS02), Specific Target Organ Toxicity – Single Exposure (GHS07)

Hazard Statements: Flammable liquid and vapour; May cause respiratory irritation.

UN Number: UN 1157

Hazard Class: 3 (Flammable Liquids)

Packing Group: III

GHS02: Flammable

GHS02: Flammable GHS07: Harmful / Irritant

GHS07: Harmful / Irritant