Trimethylsilyl Chloride in Polymer Chemistry and Material Science

Trimethylsilyl chloride (TMSCl), with CAS number 75-77-4, is a colorless, volatile organosilicon compound and silyl halide with the formula (CH₃)₃SiCl. As a reactive organosilicon reagent, TMSCl is valued for its ability to introduce trimethylsilyl groups into molecules, facilitating modifications that enhance stability, volatility, and hydrophobicity. In polymer chemistry and materials science, TMSCl is essential for controlling polymer structures, modifying surfaces, and improving material interfaces, leading to advanced composites and coatings with tailored properties. This article overviews TMSCl's role in these fields, covering its chemical background, applications in polymer synthesis and modification, uses in materials science, advantages, safety considerations, and future implications.

Chemical Background: Structure and Reactivity

TMSCl consists of a central silicon atom bonded to three methyl groups and one chlorine atom, with the Si–Cl bond being the key reactive site due to its polarity. This structure enables facile nucleophilic substitution reactions. Key reactivities include hydrolysis in the presence of moisture to form trimethylsilanol and HCl, silylation of functional groups like alcohols and amines to create protective trimethylsilyl derivatives, and participation in functionalization processes. In polymer modification, this chemistry is particularly useful for end-capping chains to control molecular weight, grafting silyl groups to alter surface properties, and enhancing compatibility at interfaces, thereby improving mechanical, thermal, and chemical resistance in polymeric materials.

Role in Polymer Chemistry

3.1 Chain Termination (End-Capping)

3.1 Chain Termination (End-Capping)

TMSCl serves as an effective chain-terminating agent in the synthesis of silicone polymers, such as polydimethylsiloxanes, by reacting with active chain ends during ring-opening or condensation polymerizations. This end-capping process introduces trimethylsilyl groups, which halt further polymerization and allow precise control over molecular weight distribution and viscosity. Consequently, it influences polymer properties like elasticity, thermal stability, and processability, making it invaluable for producing tailored silicone elastomers and resins.

3.2 Surface Modification of Polymers

Silylation with TMSCl modifies polymer surfaces by converting hydrophilic groups into hydrophobic trimethylsilyl derivatives, significantly increasing water contact angles and reducing surface energy. This enhances hydrophobicity, which is crucial for applications requiring water repellency. Additionally, TMSCl improves adhesion between polymers and coatings or fillers by forming stable siloxane bonds, boosting coating durability and interfacial compatibility in composites.

3.3 Functionalization for Advanced Polymers

TMSCl introduces trimethylsilyl groups to functionalize polymers, tuning their chemical resistance by shielding reactive sites from degradation. In specialty elastomers and high-performance polymers, this leads to enhanced resistance to acids, bases, and solvents, as seen in modified silicones and fluoropolymers. Such modifications are applied in demanding environments, like aerospace and automotive components, where durability is paramount.

Applications in Materials Science

4.1 Inorganic–Organic Interfaces

TMSCl modifies inorganic surfaces such as silica, glass, and ceramics by silylating hydroxyl groups, creating hydrophobic layers that improve wetting properties. It acts as a coupling agent to bridge inorganic fillers with polymer matrices, enhancing interfacial adhesion and mechanical strength in hybrid composites. This is particularly useful in reinforcing materials like silica-filled polymers.

4.2 Thin Films and Coatings

In vapor-phase silylation, TMSCl deposits hydrophobic thin films on substrates, providing protective barriers against moisture and corrosion. These coatings find applications in electronics for insulating layers, optics for anti-reflective surfaces, and packaging for barrier enhancements. The process allows precise control over film thickness and properties.

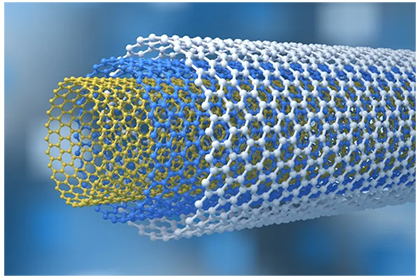

4.3 Nanomaterials and Advanced Composites

TMSCl functionalizes nanoparticles, such as silica or magnetic particles, by attaching trimethylsilyl groups to improve dispersibility and compatibility in polymer matrices. This contributes to nanocomposites with superior strength, thermal conductivity, and barrier properties against gases and liquids. Applications include advanced materials for energy storage, sensors, and structural reinforcements.

Advantages of Using TMSCl in Polymers and Materials

TMSCl offers high reactivity and efficiency in silylation reactions under mild conditions, enabling precise modifications. It allows tailoring of material properties through simple, selective reactions, such as hydrophobization or end-capping. Commercially available and cost-effective, TMSCl is compatible with scalable industrial processes, making it suitable for large-volume production.

Efficient Chain-Termination Agent

TMSCl reacts rapidly with reactive chain ends in silicone and related polymers, allowing precise control over molecular weight and end-group functionality.

Improved Surface Properties

By introducing trimethylsilyl groups, polymers and inorganic surfaces become hydrophobic and more resistant to moisture, which is valuable in coatings, packaging, and electronics.

Enhanced Compatibility in Composites

TMSCl-modified surfaces (e.g., silica fillers) bond more effectively with polymer matrices, leading to composites with better mechanical strength and improved dispersion.

Versatility in Functionalization

Applicable across a wide range of polymers, ceramics, and nanomaterials, enabling custom tailoring of chemical resistance, thermal stability, and surface energy.

Scalability and Cost-Effectiveness

As a co-product of large-scale silicone monomer production, TMSCl is relatively inexpensive and available in bulk, making it practical for industrial applications.

Compatibility with Advanced Material Processing

Suitable for use in vapor-phase treatments, thin-film coatings, and nanomaterial functionalization, supporting modern material science innovations.

TMSCl vs. Other End-Capping Agents in Polymers

| Criteria | Trimethylsilyl Chloride (TMSCl) | Other Agents (e.g., Alcohols, Acids, Bulky Silanes) |

| Reactivity | Very high reactivity due to Si–Cl bond; efficient chain termination. | Often slower or require harsher conditions. |

| Surface Modification | Produces hydrophobic trimethylsilyl surfaces, improving moisture resistance. | Varies; may give less hydrophobic or less uniform coatings. |

| Control of Polymer Properties | Precise molecular weight control; tunable end-groups. | Less predictable or more limited in scope. |

| Cost & Availability | Inexpensive; widely available as a co-product in silicone industry. | Often more costly; specialty agents made in smaller volumes. |

| Applications | Silicone end-capping, coatings, nanomaterials, composites. | Niche uses where bulkier or more stable groups are required. |

Summary: TMSCl is the go-to end-capping agent for efficiency, cost, and scalability, while alternative agents are chosen for special stability or niche requirements.

Safety and Environmental Considerations

TMSCl is corrosive, moisture-sensitive, and releases HCl upon hydrolysis, posing risks of skin burns, respiratory irritation, and flammability. Safe handling in polymer and materials labs requires PPE, fume hoods, and inert atmospheres. Environmentally, use closed systems to minimize emissions, recycle byproducts like HCl, and explore greener alternatives to reduce impact.

TMSCl holds significant importance in polymer chemistry and materials science due to its versatile reactivity in silylation and functionalization. It serves a dual role as a practical industrial reagent for everyday modifications and an enabler of advanced materials with enhanced performance. For further reading, explore applications of TMSCl in pharmaceuticals and biotechnology.

Related Articles

Trimethylsilyl Chloride Structure and Chemical Properties Explained

How is Trimethylsilyl Chloride Produced? Industrial Routes and Methods

Dichlorodimethylsilane vs Trimethylchlorosilane: What's the Difference?

Applications of Trimethylsilyl Chloride in Pharmaceuticals and Biotechnology

Protecting Groups in Organic Chemistry: The Role of Trimethylsilyl Chloride

Looking for a reliable bulk supplier of Trimethylsilyl Chloride?

Aure Chemical provides Premium Trimethylsilyl Chloride (TMSCl) raw materials.

View our Trimethylsilyl Chloride (TMSCl) product page