How to purchase different types of Aluminum Sulfate

Aluminum sulfate (AL₂(SO₄)₃·xH₂O) is a versatile inorganic compound with a wide range of industrial, commercial, and municipal applications. Known primarily as a powerful coagulating agent, it plays a critical role in water purification, where it helps remove suspended particles and improve water clarity in both drinking water and wastewater treatment systems. In the paper industry, aluminum sulfate is an essential sizing agent, enhancing paper’s resistance to moisture and improving its printability. The textile sector relies on it as a mordant to fix dyes onto fabrics, ensuring vibrant and long-lasting colors. In construction, it is used to accelerate concrete setting and enhance certain building materials’ performance. Beyond these major industries, aluminum sulfate also finds uses in fireproofing compounds, leather tanning, soil pH adjustment for agriculture, and pigment production. Its cost-effectiveness, availability, and chemical efficiency have secured its place as one of the most widely used aluminum salts in global manufacturing and infrastructure.

What is Aluminum Sulfate?

Chemically, aluminum sulfate is like a "team-up" between aluminum and sulfur in the presence of oxygen. When you drop it into water,  it breaks apart into pieces (ions) that act like magnets for dirt, tiny particles, and impurities. These pieces pull the particles together into bigger clumps, making it much easier to filter them out. That’s why it’s so useful for cleaning water.

it breaks apart into pieces (ions) that act like magnets for dirt, tiny particles, and impurities. These pieces pull the particles together into bigger clumps, making it much easier to filter them out. That’s why it’s so useful for cleaning water.

Chemical Properties

Chemical formula: AL₂(SO₄)₃·xH₂O

Molar mass: 342.15 (as Al₂(SO₄)₃)

Chemical nature: A salt formed from the reaction of aluminum hydroxide (or aluminum oxide) with sulfuric acid.

Solubility: Highly soluble in water, forming an acidic solution.

Reactivity: When dissolved in water, aluminum sulfate undergoes hydrolysis, producing aluminum hydroxide Al(OH)3 and sulfuric acid, which is the basis for its coagulating action in water treatment.

Physical Properties

Appearance: White to off-white crystalline solid or powder.

Odor: Odorless.

Density: Around 2.67 g/cm³ (anhydrous).

Melting point: ~770 °C (decomposes before boiling).

Hygroscopic nature: Tends to absorb moisture from the air.

The main chemical forms of Aluminum Sulfate

Anhydrous Aluminum Sulfate

Anhydrous aluminum sulfate Al₂(SO₄)₃ is a pure, water-free form of the compound. It is a white, crystalline solid with no water molecules in its chemical structure. Its lack of water makes it very hygroscopic, meaning it readily absorbs moisture from the air. This form has the highest concentration of aluminum sulfate by weight, which is useful in applications where a high concentration of the active compound is needed without the bulk of water. It is a key ingredient in firefighting foams and a mordant in textile dyeing.

Hydrated Aluminum Sulfate

Hydrated aluminum sulfate is the more common form found in commerce and nature. It contains water molecules H₂O bound to the aluminum sulfate structure. The most common hydrated form is aluminum sulfate octadecahydrate Al₂(SO₄)₃·18H₂O, which is a white crystalline solid or powder. The presence of water significantly increases its molecular weight and lowers its melting point compared to the anhydrous form. This is the "alum" used in water purification; when it dissolves in water, it forms aluminum hydroxide gel, which clumps together impurities and makes them easier to remove. Its uses include water and wastewater treatment, paper manufacturing, and as a soil acidifier for gardening.

Liquid Aluminum Sulfate

Liquid aluminum sulfate is a pre-dissolved solution of aluminum sulfate in water. It's not a different chemical compound, but a convenient and ready-to-use product. This solution is typically clear to slightly tinted and highly acidic, with a pH of 1.4-2.6. It's often sold as a 48% solution, which means it contains 48% dry aluminum sulfate by weight. Its main advantage is ease of use and handling; it eliminates the need for on-site mixing and dissolving of solid forms, which can be time-consuming and hazardous. Liquid aluminum sulfate is primarily used in large-scale applications like municipal water treatment plants and industrial wastewater management.

Aluminium sulfate is commercially available in a variety of chemical forms. The following are the characteristics and applications of each form:

| Form | Common Industries | Application Range | Pros | Cons |

| Anhydrous Aluminum Sulfate Al₂(SO₄)₃ | Specialty chemical manufacturing, pigments, catalysts | Used in chemical synthesis requiring minimal water content, catalyst preparation, specialty pigment production, certain highpurity industrial processes | High purity with no water content Longer storage stability if kept dry Suitable for processes sensitive to moisture | Slower dissolution rate in waterLess common, higher cost Requires more handling precautions to prevent dust |

| Hydrated Aluminum Sulfate Al₂(SO₄)₃·xH₂O | Water treatment, paper manufacturing, textiles, agriculture | Drinking water and wastewater treatment, paper sizing, textile dye fixation, soil pH adjustment, leather tanning | Readily available and lowcost Dissolves quickly in water Easier to handle in solid dosing systems Effective for flocculation in water treatment | Higher bulk weight due to water content Can absorb more moisture and cake during storageRequires dry storage conditions |

| Liquid Aluminum Sulfate Solution | Municipal water treatment, industrial wastewater treatment, largescale continuous dosing | Continuous coagulation in municipal plants, industrial effluent treatment, automated dosing systems, largescale cooling water systems | Readytouse, no need for dissolution Eliminates dust hazardEasy to automate dosing Uniform product quality | Requires tank storage and pumps Higher shipping cost due to water weight Shorter shelf life compared to solid forms |

Simply put: Aluminium sulfate can be sold as a dry powder, hydrated crystals, or a ready-to-use liquid. Different industries will choose the most suitable form based on their equipment, storage conditions, and application requirements.

Physical Forms of Aluminum Sulfate

Aluminum sulfate is available in several physical forms to suit different industrial applications, handling requirements, and storage conditions. The most common forms include:

| Forms | Appearance | Advantages | Typical Uses | Considerations |

| Powder | Fine, white to off-white powder. | Dissolves quickly in water, providing rapid coagulation effects in water treatment. Easy to measure and mix in laboratory or small-scale applications. | Small-scale water purification, laboratory testing, specialty chemical formulations. | Can generate dust during handling, requiring dust control measures. |

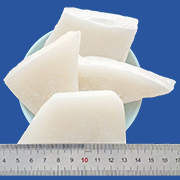

| Lumps | Large, irregular solid chunks or crystalline blocks. | Lower dust hazard compared to powder; longer storage stability; less prone to caking. | Bulk industrial applications where product is dissolved in tanks before use, such as municipal water treatment plants. | Requires more time and agitation to dissolve completely. |

| Granules | Uniform small pellets or coarse crystals. | Low dust, good flowability, easier dosing than lumps, and faster dissolution than large chunks. | Water treatment facilities, paper mills, and industries preferring clean and efficient solid handling. | Still requires dissolution before application; bulk handling systems recommended. |

| Liquid Solution | Clear to slightly cloudy liquid, usually with Al₂O₃ 8–14% content. | Ready-to-use without dissolution, easily metered for continuous dosing systems, eliminates dust issues. | Municipal water plants, industrial wastewater treatment, large-scale automated systems. | Requires dedicated storage tanks, pumping systems, and more expensive transport due to water weight. |

The following are the different forms of Aluminum Sulfate provided by Aure Chemical. We offer various types of products, including No-ferric Aluminum Sulfate, Industrial Aluminum Sulfate, and High-purity Aluminum Sulfate. If you would like to learn more about the different product forms and their applications, please contact us and let us know your specific needs.

Grades of Aluminum Sulfate Based on Iron Content

Aluminum sulfate is often classified by iron (Fe) content, which affects its color, purity, and suitability for different industries. The iron content typically comes from raw bauxite or alumina sources used in production.

1. Low-Iron Grade (Iron-free grade)

Typical Fe content: ≤ 0.005%–0.01% (50–100 ppm)

Appearance: Pure white crystalline solid or clear solution.

Effects of low Fe

Maintains high whiteness and brightness.

Prevents discoloration in products such as paper and textiles.

Minimizes staining in treated water.

Applications:

Paper industry — especially high-grade printing and writing paper.

Textile dyeing and finishing — where color purity is important.

Water treatment for food & beverage industries — to avoid any color contamination.

Cosmetics and pharmaceuticals — where purity standards are strict.

2. Medium-Iron Grade

Typical Fe content: ~0.01%–0.5%

Appearance: Off-white to light yellow solid or solution.

Effects of medium Fe:

Slightly lower whiteness; may cause mild color tint in final products.

Acceptable for most industrial processes where appearance is not critical.

Applications:

Municipal water treatment — potable water coagulation.

Industrial wastewater treatment — where slight color is not an issue.

Construction — concrete setting accelerators, waterproofing compounds.

3. High-Iron Grade

Typical Fe content: >0.5% (sometimes up to 1–1.5%)

Appearance: Yellowish to brown solid or dark solution.

Effects of high Fe:

Pronounced coloration; unsuitable for whiteness-critical applications.

May provide additional coagulation assistance in certain wastewater treatments due to iron salts.

Applications:

Industrial wastewater treatment — especially in mining, heavy metals removal, and high-turbidity effluents.

Non-critical paper products — corrugated board, cardboard where brightness is not a requirement.

Soil pH adjustment — agriculture and horticulture.

Impact of Iron Content on Aluminum Sulfate Performance

Color & Purity: Higher iron content darkens the product and can affect brightness in paper/textiles.

Coagulation Efficiency: Iron can slightly enhance coagulation in some cases, but may also impart color to the treated water.

Market Price: Low-iron grades are more expensive due to additional refining processes.

Industry Suitability: Purity requirements dictate which grade is acceptable — for example, food-grade water treatment requires very low Fe content.

Applications of Aluminum Sulfate

Water and Wastewater Treatment Click to learn more

Drinking Water Purification: Acts as a coagulant, causing suspended particles, microorganisms, and organic matter to clump together into larger flocs that can be removed by sedimentation and filtration.

Industrial Wastewater Treatment: Used to remove color, oil, heavy metals, and other contaminants from effluents.

Stormwater Management: Helps reduce turbidity and pollutant loads in runoff water.

Paper Manufacturing Click to learn more

Sizing Agent: Improves paper resistance to water and ink penetration, enhancing print quality.

Filler Retention: Helps retain fillers, pigments, and other additives in the paper pulp during manufacturing.

pH Adjustment: Controls pH levels in the papermaking process to improve efficiency.

Textile Industry Click to learn more

Mordant for Dyeing: Binds dyes to fibers, ensuring vibrant, long-lasting colors.

Color Fixing: Improves colorfastness of dyed fabrics.

Construction and Building Materials Click to learn more

Concrete Additive: Speeds up setting time in cold weather conditions.

Waterproofing Compounds: Improves resistance of building materials to water penetration.

Soil Stabilization: Helps bind soil particles in road construction and erosion control.

Agriculture and Soil Management Click to learn more

Soil pH Control: Lowers soil pH in alkaline soils, making nutrients more available to plants.

Hydrangea Color Modification: Shifts hydrangea flower color toward blue by increasing soil acidity.

Leather Tanning Click to learn more

Pickling Agent: Prepares hides for tanning by swelling and softening the collagen fibers.

Fireproofing Click to learn more

Fire Retardant: Used in treatment of fabrics, wood, and paper products to reduce flammability.

Choose a Reliable Aluminum Sulfate Supplier

Selecting a reliable aluminum sulfate supplier is a critical step in ensuring product quality and production efficiency. In addition to the points mentioned above, there are many other details worth paying attention to. If you would like to learn more about how to conduct on-site inspections and how to evaluate a supplier's production capacity and technical support, we have prepared a more detailed article for you.

“How to Select a Reliable Aluminum Sulfate Supplier” Click the link to view the complete guide.

Related Articles

Looking for a reliable bulk supplier of Aluminum Sulfate (CAS 10043-01-3)?

Aure Chemical provides Premium Aluminum Sulfate raw materials.

View our Aluminum Sulfate product page