The Use of Aluminum Sulfate in Water and Wastewater Treatment

Aluminum Sulfate, commonly known as aluminium sulphate and with the chemical formula AL₂(SO₄)₃·xH₂O, is a widely used inorganic coagulant in both water treatment (for potable water production) and wastewater treatment (municipal, industrial, and stormwater). It is a white, crystalline substance that dissolves readily in water, making it cost-effective and efficient for large-scale applications. Aluminum Sulfate has been employed in water purification since ancient times but gained prominence in modern treatment processes during the 19th century. Its primary function is to facilitate the removal of impurities through coagulation and flocculation, transforming cloudy or polluted water into clearer, safer effluent. In water treatment, it helps produce drinking water by reducing contaminants, while in wastewater treatment, it aids in meeting discharge standards and preventing environmental issues like eutrophication. Aluminum Sulfate's versatility stems from its ability to react with water's alkalinity, forming charged species that interact with pollutants.

Role as a Flocculant and Flocculant Aid

In water and wastewater treatment, Aluminum Sulfate serves primarily as a coagulant but also functions as a flocculant or flocculant aid, playing a key role in the coagulation-flocculation process—a critical step in physical-chemical treatment.

As a Coagulant: When added to water during rapid mixing (flash mix), Aluminum Sulfate dissociates into trivalent aluminum ions (Al³⁺) and sulfate ions. These positively charged Al³⁺ ions neutralize the negative surface charges on colloidal particles (e.g., clay, silt, organic matter, and microorganisms), reducing electrostatic repulsion. This destabilization allows particles to collide and aggregate, marking the coagulation phase. Coagulation is essential for initiating the removal process, as untreated particles are too small and stable to settle naturally.

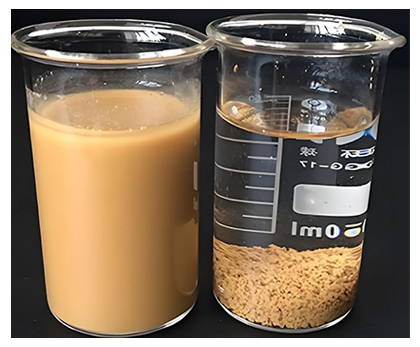

As a Flocculant and Flocculant Aid: Following coagulation, during gentle

slow mixing in the flocculation basin, Aluminum Sulfate hydrolyzes further, reacting with water's alkalinity to form a gelatinous precipitate of aluminum hydroxide (Al(OH)₃). This sticky "floc" acts like a web, entrapping destabilized particles and forming larger, heavier aggregates. Aluminum Sulfate thus aids flocculation by providing a bridging mechanism, where the floc binds particles together. It is often used with organic polymers (e.g., cationic polyamidine) as flocculant aids to enhance floc size, strength, and settling speed, improving overall efficiency. This dual role—charge neutralization and floc formation—makes Aluminum Sulfate versatile, though its performance depends on factors like pH (optimal 5.5–7.5), temperature, and dosage, often determined via jar tests.

slow mixing in the flocculation basin, Aluminum Sulfate hydrolyzes further, reacting with water's alkalinity to form a gelatinous precipitate of aluminum hydroxide (Al(OH)₃). This sticky "floc" acts like a web, entrapping destabilized particles and forming larger, heavier aggregates. Aluminum Sulfate thus aids flocculation by providing a bridging mechanism, where the floc binds particles together. It is often used with organic polymers (e.g., cationic polyamidine) as flocculant aids to enhance floc size, strength, and settling speed, improving overall efficiency. This dual role—charge neutralization and floc formation—makes Aluminum Sulfate versatile, though its performance depends on factors like pH (optimal 5.5–7.5), temperature, and dosage, often determined via jar tests.

The formed flocs then proceed to sedimentation (where they settle as sludge) and filtration (for final polishing), significantly clarifying the water.

Removal of Turbidity

Turbidity refers to the cloudiness caused by suspended solids like clay, silt, algae, and organic debris, which can harbor pathogens and interfere with disinfection. Aluminum Sulfate removes turbidity through the following mechanism:

Charge Neutralization and Aggregation: The Al³⁺ ions adsorb onto negatively charged particles, neutralizing their zeta potential (surface charge). This reduces repulsion, enabling particles to form microflocs during coagulation.

Floc Formation and Settling: In flocculation, these microflocs grow into larger flocs via the aluminum hydroxide precipitate, which sweeps up additional particles through adsorption and enmeshment. The heavy flocs settle in clarification tanks, removing 95–99% of turbidity in many cases. Remaining fine flocs are captured in filters.

Practical Effectiveness: Studies show Aluminum Sulfate achieves rapid settling and high turbidity removal, even in low-temperature or low-turbidity waters. For example, in stormwater treatment, it reduces suspended solids by 95–99%, restoring clarity in ponds and lakes within 24–48 hours when dosed at 25–50 lbs per acre-foot. However, overdosing can increase residual turbidity, so optimization is key.

Removal of Phosphorus

Phosphorus, often from detergents, fertilizers, or industrial effluents, contributes to eutrophication (algal blooms) in receiving waters. Aluminum Sulfate is highly effective for chemical phosphorus removal, particularly orthophosphates:

Phosphorus, often from detergents, fertilizers, or industrial effluents, contributes to eutrophication (algal blooms) in receiving waters. Aluminum Sulfate is highly effective for chemical phosphorus removal, particularly orthophosphates:

Precipitation Mechanism: Al³⁺ ions react with phosphate ions (PO₄³⁻) to form insoluble aluminum phosphate (AlPO₄), as per the reaction: Al³⁺ + PO₄³⁻ → AlPO₄ ↓. This precipitate integrates into the floc matrix during coagulation-flocculation.

Adsorption and Binding: Excess Aluminum Sulfate forms aluminum hydroxide, which adsorbs additional phosphorus compounds onto its surface. This is enhanced in tertiary treatment stages, where Aluminum Sulfate is added post-biological processes.

Efficiency and Applications: Removal rates can reach 90% or higher, with dosages of 5–10 mg/L in wastewater. In lakes, Aluminum Sulfate binds phosphorus in sediments, preventing release. It's more efficient than biological methods alone, though it competes with other anions (e.g., sulfates) for reaction sites, requiring higher doses in complex waters. pH adjustment ensures optimal precipitation, as low pH favors AlPO₄ formation.

Removal of Other Pollutants

Beyond turbidity and phosphorus, Aluminum Sulfate addresses a broad range of pollutants through similar mechanisms:

Suspended Solids and Organics: Aggregates remove total suspended solids (TSS), biochemical oxygen demand (BOD), chemical oxygen demand (COD), and total organic carbon (TOC) by enmeshment in flocs, achieving 50–90% reductions.

Heavy Metals and Color: Aluminum Sulfate precipitates metals (e.g., iron, manganese, heavy metals like lead) as hydroxides or phosphates, and adsorbs colored organics (e.g., humic acids). Removal rates for heavy metals can be 50–90%.

Microorganisms and Other Contaminants: Flocs entrap bacteria, viruses, and protozoa, aiding disinfection. It also reduces hydrogen sulfide, fluoride, and microplastics via coagulation. In wastewater, it lowers ammonium indirectly through pH changes and complexation.

Overall Process: These removals occur during sedimentation/filtration, with sludge byproduct often requiring management (e.g., dewatering or reuse as fertilizer, though high Al content can limit plant availability).

Considerations and Challenges

Aluminum Sulfate is cost-effective and adaptable but increases sludge volume, potentially raising disposal costs. Residual aluminum must be monitored to avoid toxicity (e.g., <0.2 mg/L in drinking water). Alternatives like ferric chloride may be used for specific needs, and combining Aluminum Sulfate with polymers optimizes performance. Environmental regulations (e.g., Clean Water Act) mandate proper dosing to minimize impacts.

In summary, aluminum sulfate is a cornerstone of water and wastewater treatment, excelling in coagulation-flocculation to remove diverse pollutants efficiently and economically, ensuring safer water resources.

How is Aluminum Sulfate used in Water Treatment? Click to learn more

Related Articles

Looking for a reliable bulk supplier of Aluminum Sulfate (10043-01-3)?

Aure Chemical provides Premium Aluminum Sulfate raw materials.

View our Aluminum Sulfate product page