The Future of Flexible Tech: Unlocking the Secrets of Colourless Transparent Polyimide Films

Ever wondered what makes your smartphone's flexible screen bend without breaking, or how next-gen solar panels can roll up like a poster? It's all thanks to a revolutionary material called Colourless Transparent Polyimide (CPI) film. This high-tech polymer is transforming industries from electronics to aerospace, offering crystal-clear transparency combined with unbeatable durability. In this post, we'll dive into what CPI is, how it's made, its exciting applications, and its evolution over the decades. Let's explore why CPI is the unsung hero of modern innovation!

What is Polyimide and Why Does Color Matter?

Polyimide (PI) is a powerhouse polymer known for its exceptional properties. Its rigid aromatic and imide ring structures give it top-notch thermal resistance, chemical stability, flexibility, and mechanical strength. PI materials excel in dimensional stability, dielectric properties, and radiation resistance, making them staples in aerospace, electronics, electrical appliances, and composites.

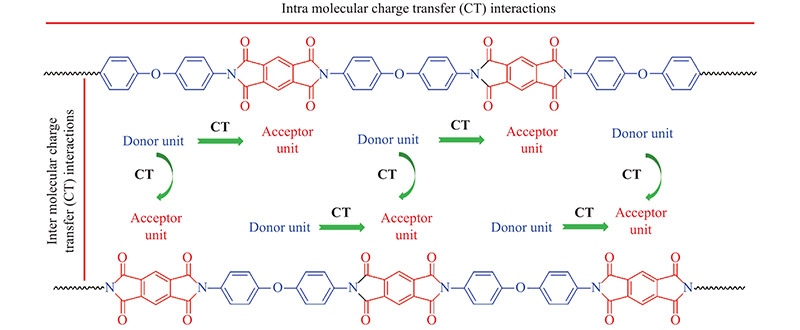

Traditional PI films are brown or amber-colored, which limits their use in optics and displays. This color comes from charge-transfer complexes (CTCs) formed by electron donors and acceptors in the molecular structure. These complexes absorb visible light, resulting in low transmittance—less than 40% at 500 nm and almost total absorption at 400 nm.

Enter Colourless Transparent Polyimide (CPI)

CPI takes PI to the next level with superior optical clarity, low dielectric constant, high thermal stability, and strong mechanical performance. It's a game-changer for microelectronics and optoelectronics.

CPI acts as an encapsulation material, a nonlinear optical material, a film alignment agent in LCDs, flexible cover glass in OLEDs, and more. It's essential for flexible displays and printed circuit boards.

Here's a quick look at the performance benchmarks for CPI films:

| Item | Unit | Performance Requirement |

| Light transmittance | % | >90 |

| Yellow index | - | <5 |

| Tg | ℃ | >300 |

| T5% | ℃ | >450 |

| Coefficient of thermal expansion | ℃⁻¹ | <20×10⁻⁶ |

| Modulus of elasticity | GPa | >1.00 |

| Tensile strength | MPa | >100 |

| Elongation at break | % | >10 |

| Birefringence | - | <0.01 |

| Dielectric constant | F·m⁻¹ | <3.00 |

This table highlights why CPI is ideal for demanding applications.

How Are CPI Films Prepared?

To create CPI, we tweak the monomers before synthesis to break conjugated interactions and eliminate CTCs. This improves transparency but can trade off other properties, so smart molecular design is key to balance everything.

The main strategies involve adding fluorinated groups, alicyclic structures, non-coplanar structures, meta-substitutions, or sulfonyl groups to the backbone. This boosts transmittance and lowers the yellow index. CPI films fall into three main categories: fluorinated, alicyclic, and non-coplanar.

Fluorinated CPI Films

Fluorine atoms' high electronegativity blocks electron movement, curbing CTCs for clearer films. They also increase free space between chains, improving dielectric properties.

Groups like trifluoromethyl or hexafluoroisopropyl widen chain gaps, enhancing solubility and reducing dielectric constants. However, fluorine can weaken mechanical strength, thermal stability, and adhesion. It also lowers monomer reactivity, making high-molecular-weight polymers harder to achieve.

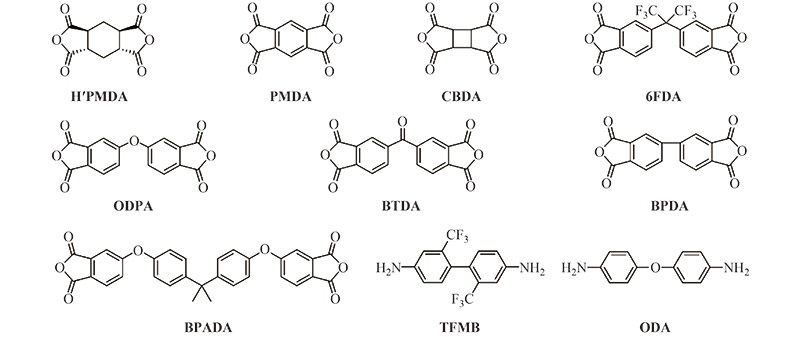

Mixing in non-fluorinated monomers helps maintain heat resistance while keeping transparency. The star fluorinated dianhydride is 6FDA, produced globally by DuPont.

Alicyclic CPI Films

Alicyclic structures break up aromatic conjugations, reducing interactions and boosting free volume. This leads to better transparency, solubility, and thermal stability.

But alicyclic dianhydrides are less reactive, leading to lower molecular weights. Aliphatic diamines can form salts during polymerization, complicating things. Fully alicyclic PIs are highly transparent but lack aromatic rigidity, hurting thermal properties.

Semi-aromatic hybrids combine the best of both worlds and are gaining traction. Commercial alicyclic monomers include CBDA, HPMDA, BTA, and BTDA.

Non-Coplanar CPI Films

Non-coplanar structures twist the chains, increasing distances and reducing density. This cuts CTCs and improves optics without harming rigidity, preserving mechanical and thermal stability.

While less effective than fluorinated or alicyclic approaches for optics, non-coplanar designs pair well with them for synergistic benefits.

Other Variants

Sulfonyl groups and ether bonds twist the backbone, suppressing charge transfer and enhancing optics—but at the cost of thermal stability.

Innovative designs, like rearranging ester groups in dianhydrides, lower electron affinity, boost transparency, reduce moisture absorption, and raise Tg.

Certain commercial Polyimide -Diamine monomers and Polyimide -Dianhydride monomers

Real-World Applications of CPI Films

CPI's blend of thermal, insulating, and transparent qualities makes it perfect for cutting-edge tech.

Flexible Display Substrates

Flexible substrates support and transmit light in displays. Options include thin glass, polymers, and metal foils. Polymers like CPI offer the best mix of transparency and flexibility.

CPI's high strength and stability make it a top pick alongside PET for flexible screens.

Flexible Thin-Film Solar Cells

Ditching heavy glass for CPI substrates creates lightweight, affordable solar cells via vacuum deposition. They're flexible and easy to produce.

Flexible Printed Circuit Boards

As devices slim down, CPI provides thin, light, transparent, and heat-resistant packaging—ideal for future flexible electronics.

The Evolution of CPI Films

CPI's story starts in 1967 with DuPont's patents on key fluorinated monomers like 6FDA and 6FDAM.

In the 1980s, NASA and Soviet researchers pushed for space-grade transparent films, spotlighting 6FDA-based CPI.

The 1990s saw rapid commercialization for optoelectronics. NTT explored fiber-optics uses, while NASA's LaRC-CP1® and LaRC-CP2® went into production, proving durable in orbit.

Today, leaders include DuPont, Zymergen, Mitsubishi Gas Chemical, Toray-DuPont, KANEKA, TOYOBO, Mitsui Chemicals, KOLON, SKC, RAYITEK, and Taimide.

Looking Ahead: The Bright Future of CPI

Colourless Transparent Polyimide films are revolutionizing flexible tech, from bendable screens to rollable solar panels. By mastering molecular tweaks like fluorination and alicyclic structures, we've achieved materials that balance transparency, strength, and heat resistance. As global production ramps up—especially in China—the costs will drop, opening doors to even more innovations. Whether in space exploration or everyday gadgets, CPI's potential is limitless. Stay tuned for what's next in this exciting field! If you're in the chemicals industry, check out Aurechem's latest offerings to see how we're contributing to this wave.