Lithium Triflate vs Lithium TFSI: Which Electrolyte Performs Better?

In lithium-ion and solid-state battery development, the choice of electrolyte salts is a critical factor influencing ionic conductivity, interfacial stability, and overall battery lifespan. Among the various options, Lithium Triflate (LiCF₃SO₃) and Lithium TFSI (LiN(SO₂CF₃)₂, also known as lithium bis(trifluoromethanesulfonyl)imide or LiTFSI) are prominent for their balance of properties. Lithium Triflate, with its simpler structure, offers cost advantages and reliability in moderate applications, while Lithium TFSI excels in high-performance scenarios due to its superior stability and conductivity. This article provides a detailed comparison of LiCF3SO3 vs LiTFSI, examining chemical structure, performance metrics, compatibility, safety, and cost to guide researchers, formulators, and purchasing specialists in selecting the optimal lithium electrolyte.

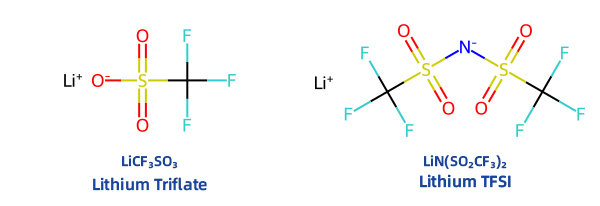

Chemical Structure and Fundamental Differences

The chemical structures of Lithium Triflate and Lithium TFSI underpin their distinct behaviors in electrolyte systems. Lithium Triflate has the formula LiCF₃SO₃, featuring a small triflate anion (CF₃SO₃⁻) with a single sulfonate group attached to a trifluoromethyl moiety. This anion is relatively compact, with a molecular weight of approximately 149 g/mol for the anion alone. In contrast, Lithium TFSI (LiN(SO₂CF₃)₂) possesses a larger, more complex anion (N(SO₂CF₃)₂⁻), consisting of a nitrogen core flanked by two trifluoromethanesulfonyl groups, resulting in a higher anion molecular weight of about 280 g/mol.

The key difference lies in charge delocalization. In Lithium TFSI, the negative charge is highly delocalized across the nitrogen and sulfonyl groups, reducing ion-pairing with Li⁺ cations and promoting better dissociation in solvents. This delocalization is facilitated by the symmetric structure and strong electron-withdrawing CF₃ groups, leading to weaker coordination with lithium ions. Lithium Triflate's anion, while also fluorinated, has less delocalization, resulting in stronger ion associations and potentially lower mobility.

From a crystallographic perspective, Lithium TFSI exhibits a more flexible, bulkier anion that enhances solubility and reduces crystallinity in polymer electrolytes, whereas Lithium Triflate's smaller size can lead to higher hygroscopicity and moisture sensitivity. Both salts are white crystalline solids at room temperature, but Lithium TFSI demonstrates lower hydrophobicity due to its structure, making it less prone to water absorption—a critical factor in battery applications where moisture can cause decomposition and HF formation.

| Property | Lithium Triflate (LiCF₃SO₃) | Lithium TFSI (LiN(SO₂CF₃)₂) |

| Molecular Formula | LiCF₃SO₃ | LiN(SO₂CF₃)₂ |

| Anion Size | Smaller | Larger, more delocalized |

| Ionic Dissociation | Moderate | Very high |

| Hygroscopicity | Higher | Lower |

| Typical Purity | ≥99.5% | ≥99.9% |

These structural variances directly impact their performance, with Lithium TFSI generally offering superior electrochemical properties at the expense of higher complexity and cost.

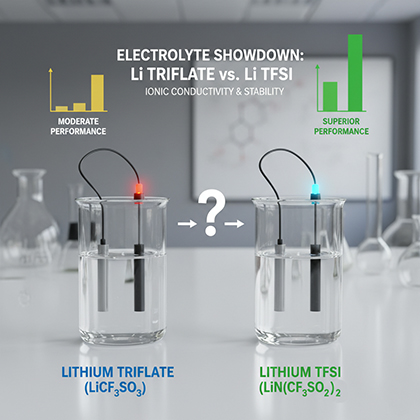

Ionic Conductivity and Electrochemical Stability

Ionic conductivity and electrochemical stability are pivotal for electrolyte performance in lithium batteries, determining charge-discharge rates and operational voltage ranges. Lithium TFSI outperforms Lithium Triflate in both metrics, primarily due to its highly delocalized anion, which facilitates greater ion mobility and reduced viscosity in electrolyte solutions.

In liquid electrolytes, such as those based on carbonates (e.g., EC/DMC), Lithium TFSI achieves ionic conductivities often exceeding 10 mS/cm at room temperature, compared to 5–8 mS/cm for Lithium Triflate under similar conditions. This superiority arises from TFSI's weaker binding to Li⁺, leading to higher dissociation constants and lower ion-pair formation. For instance, in glyme-based electrolytes, LiTFSI systems exhibit conductivities up to 10⁻² S/cm, enabling faster lithium transport and better rate capabilities in batteries.

Electrochemical stability is another area where Lithium TFSI shines, with a wider window of approximately 5.0 V vs. Li/Li⁺, versus 4.5 V for Lithium Triflate. This allows LiTFSI to support high-voltage cathodes (e.g., NMC or LCO) without decomposition, reducing side reactions like anion oxidation at the cathode interface. Thermal stability follows suit: LiTFSI remains stable up to 250–300°C, while Lithium Triflate decomposes around 200°C, making TFSI more suitable for high-temperature applications or safety-critical scenarios.

In polymer electrolytes, such as PEO-based systems, LiTFSI again provides higher conductivity (e.g., 10⁻⁴ S/cm at 60°C) due to better plasticization and reduced crystallinity, compared to LiTriflate's moderate performance. However, Lithium Triflate can be advantageous in moisture-sensitive setups where its lower cost justifies use in less demanding systems.

Overall, for applications requiring high conductivity and stability, Lithium TFSI is superior, though Lithium Triflate suffices for cost-sensitive or moderate-voltage batteries.

Compatibility with Battery Systems

Compatibility with various battery architectures is essential for practical deployment. Lithium TFSI demonstrates broader versatility across liquid, gel, and solid-state systems, while Lithium Triflate is more niche-oriented.

In liquid lithium-ion cells, LiTFSI is preferred for high-voltage (>4.2 V) and low-temperature operations, where it maintains conductivity down to -40°C without freezing. It forms stable solid electrolyte interphases (SEI) on anodes like graphite or silicon, enhancing cycle life (e.g., >1000 cycles at 80% capacity retention). Lithium Triflate, while compatible, shows higher SEI resistance and poorer low-temperature performance, limiting its use in electric vehicles or grid storage.

For solid polymer electrolytes (SPEs), both salts are used, but LiTFSI delivers superior ion transport in PEO or PVDF matrices, supporting flexible and safe solid-state batteries. In ionic liquid-based systems, LiTFSI's low volatility and high stability make it ideal for non-flammable electrolytes, whereas Lithium Triflate is less compatible due to potential hydrolysis.

In non-battery applications like catalysis, Lithium Triflate excels as a mild Lewis acid for organic synthesis (e.g., ester additions), offering simpler handling than the more expensive LiTFSI. Thus, while LiTFSI dominates cutting-edge battery formulations, Lithium Triflate remains valuable in cost-sensitive or catalytic contexts where moderate conductivity is adequate.

Safety, Handling, and Environmental Aspects

Safety and handling considerations are crucial for electrolyte salts, given their use in energy-dense systems. Lithium Triflate is more hygroscopic, absorbing moisture readily, which can lead to hydrolysis and HF formation if not stored properly. It requires sealed, inert atmosphere storage to prevent degradation, but its handling is straightforward with standard PPE (gloves, goggles). In battery applications, it poses lower thermal runaway risks due to moderate stability but may generate toxic byproducts under abuse conditions.

Lithium TFSI offers better moisture resistance, reducing handling challenges, but its decomposition can produce HF and SO₂, necessitating robust ventilation. Both salts are non-flammable, but LiTFSI's higher stability enhances overall battery safety, minimizing dendrite formation and short circuits in solid-state designs.

Environmentally, both are fluorine-containing, raising concerns about persistence and bioaccumulation. Lithium Triflate is less persistent but more water-soluble, potentially impacting aquatic ecosystems if leaked. LiTFSI's larger anion makes it less mobile but harder to degrade. Proper recycling and disposal per SDS guidelines are essential, with LiTFSI often preferred for its longevity, reducing waste in long-cycle batteries.

Cost and Commercial Availability

Cost is a decisive factor for scaling battery technologies. As of October 2025, Lithium Triflate is priced at approximately USD 55–75 per kg (FOB China), benefiting from simpler synthesis and abundant precursors. Lithium TFSI, with its more complex structure, costs USD 110–140 per kg (FOB China), reflecting higher production expenses for the bis-sulfonyl anion.

Major suppliers for both include Chinese manufacturers like Hubei Xingfa and Japanese firms like Kanto Chemical, with global availability high. Production scales for LiTFSI are growing due to demand from EV batteries, potentially narrowing the price gap, but Lithium Triflate remains 40–50% cheaper, making it attractive for research or low-cost applications.

| Item | LiCF₃SO₃ (Lithium Triflate) | LiN(SO₂CF₃)₂ (Lithium TFSI) |

| Approx. Price (China FOB, 2025) | USD 55–75 /kg | USD 110–140 /kg |

| Major Suppliers | China, Japan, Europe | Japan, US, China |

| Production Scale | Medium | Large, growing |

| Availability | High | High |

Summary Table — Performance Comparison

| Parameter | Lithium Triflate | Lithium TFSI | Better Choice |

| Ionic Conductivity | Moderate (5–8 mS/cm) | High (>10 mS/cm) | LiTFSI |

| Thermal Stability | Good (~200°C) | Excellent (~250–300°C) | LiTFSI |

| Electrochemical Window | 4.5 V | 5.0 V | LiTFSI |

| Moisture Stability | Fair (hygroscopic) | Good | LiTFSI |

Conclusion — Which Performs Better?

Overall, Lithium TFSI outperforms Lithium Triflate in ionic conductivity, electrochemical and thermal stability, and compatibility with advanced battery systems, making it the preferred choice for high-voltage, long-life applications like electric vehicles and solid-state batteries. Its superior anion delocalization enables better ion transport and reduced degradation, though at a higher cost. Lithium Triflate, however, offers a compelling alternative for cost-sensitive scenarios, such as laboratory research, moderate-performance electrolytes, or catalytic uses where its simpler structure and affordability shine. The optimal selection depends on specific requirements: prioritize LiTFSI for cutting-edge performance and LiCF3SO3 for economic viability. As battery technology evolves, ongoing innovations may further bridge these gaps, but for now, Lithium TFSI holds the edge in demanding lithium electrolyte comparisons.

Related Articles

Looking for a reliable bulk supplier of Lithium Triflate?

Aure Chemical provides Premium Lithium Triflate (CAS 33454-82-9).

View our Lithium Triflate product page