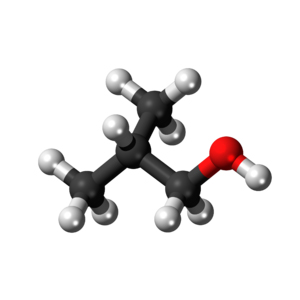

Isobutanol: Your Guide to a Key Industrial Solvent and Raw Material

Isobutanol is an organic compound with a variety of industrial applications. It is a colourless, flammable liquid with a distinctive pungent odour. As an important chemical raw material and solvent, isobutanol plays a key role in many fields, including coatings, fuels, pharmaceuticals, and cosmetics.

Basic Properties and Physical and Chemical Characteristics

Isobutanol, also known as 2-methyl-1-propanol, has the chemical formula C₄H₁₀O. It is a colourless, transparent liquid at room temperature. The following are its main physical and chemical properties:

| Properties | Value |

| Molecular weight: | 74.122 g/mol |

| CAS number: | 78-83-1 |

| Density: | 0.803 g/cm³ |

| Melting point: | -108 °C |

| Boiling point: | 108 °C |

| Flash point: | 27.8 °C |

| Solubility: | Slightly soluble in water, easily soluble in organic solvents such as ethanol and ether. |

Isobutanol is flammable, and its vapours can form explosive mixtures when mixed with air. It is prone to ignition when exposed to open flames or high temperatures. Additionally, it can react violently with oxidisers.

Production Methods

There are primarily two industrial methods for producing isobutanol:

By-product of propylene carbonylation synthesis: During the production of butanol or octanol via propylene carbonylation synthesis, isobutyraldehyde is generated as a by-product. This isobutyraldehyde can be converted into isobutanol through a hydrogenation reaction.

Conversion of isobutylene or tert-butanol: Catalytic oxidation of isobutylene or tert-butanol to produce methyl acrolein, followed by hydrogenation, can also yield isobutanol.

Additionally, bio-based production methods aligned with green chemistry trends are gaining attention, involving fermentation using microorganisms or biomass to produce isobutanol.

Main Application Areas

Isobutanol, with its excellent solubility and other chemical properties, is widely used in various industries:

Solvent Industry: Isobutanol serves as a co-solvent for nitrocellulose and is an excellent solvent for ethyl cellulose, various resins, and rubber. It is commonly used in paints, inks, and coatings as a replacement for more toxic solvents such as benzene. In the electronics industry, it is also used for cleaning precision instruments and semiconductor components.

Chemical Raw Materials: As a basic chemical raw material, isobutanol is used in the production of various chemicals. For example, it is used in the synthesis of plasticisers (such as phthalates), the production of isobutyl esters (such as isobutyric acid isobutyl ester) for fragrances and food additives, and the manufacture of isobutylene for synthetic rubber and lubricant additives.

Fuels and additives: Isobutanol has a high energy density and can be blended with gasoline as a biofuel to increase octane ratings and reduce carbon emissions. It is also an intermediate in the production of biojet fuel.

Pharmaceuticals and cosmetics: In the pharmaceutical industry, isobutanol serves as an intermediate in the synthesis of antibiotics, vitamins, and other drugs. In the cosmetics industry, it is used as a solvent or fixative in perfumes and cosmetics.

Other applications: Isobutanol can also be used as a petroleum additive, antioxidant, and solvent or adjuvant in pesticides. Additionally, it is employed in the purification of salts such as strontium, barium, and lithium.

Safety and Storage

Isobutanol is a flammable liquid with a UN number of 1212. The following safety precautions should be observed during storage and use:

Health Hazards: Isobutanol vapours are irritating to the eyes, skin, and respiratory tract. Its toxicity is lower than that of methanol and propanol, but its anaesthetic effect is slightly stronger than that of butanol. The maximum allowable concentration in the workplace is 100 ppm.

Firefighting Measures: When extinguishing fires, use alcohol-resistant foam, dry powder, or sand. Avoid direct water jet application.

Storage Requirements: Store in a cool, well-ventilated warehouse. Storage temperature should not exceed 30°C. Keep separate from oxidisers and acidic substances. Storage containers may be made of iron, mild steel, copper, or aluminium.

Advantages and Challenges

Advantages:

Good solubility: It can dissolve various resins, oils, and other organic substances, with solubility superior to that of ethanol and n-butanol.

High boiling point: Compared to ethanol and methanol, its higher boiling point makes it more stable in high-temperature processes.

Low toxicity and volatility: Compared to solvents like methanol, isobutanol has relatively lower volatility and toxicity to humans.

Green production potential: It can be produced through biological fermentation, aligning with sustainable development requirements.

Disadvantages:

Strong odour: It has a strong alcohol-like odour, which may affect the work environment.

Production cost: Its synthesis or fermentation cost is relatively higher than that of methanol and ethanol.

Flammability: It has a low flash point and is classified as a flammable liquid, requiring careful handling.

Biodegradability: Its degradation rate in natural environments is slower than that of short-chain alcohols like ethanol.

In summary, isobutanol occupies an important position in modern industry due to its versatility, but throughout the entire production and application process, relevant safety regulations must be strictly adhered to in order to ensure the safety of personnel and the environment.