Cyclohexanone vs Cyclohexane: What is the Difference?

Cyclohexane and Cyclohexanone are two important organic compounds in the field of industrial chemistry, both featuring a six-carbon cyclic structure. Cyclohexane is a simple saturated hydrocarbon, while cyclohexanone is its oxidized derivative containing a ketone functional group. These compounds are often compared due to their structural similarities as C6 cyclic molecules, their close linkage in production processes, and their shared significance in the manufacturing of nylon polymers. Cyclohexane serves as a key feedstock that is oxidized to produce cyclohexanone, which in turn is converted into precursors for nylon-6 and nylon-66.

The aim of this article is to clarify the similarities and differences between cyclohexanone and cyclohexane, providing valuable insights for researchers, students, and industry professionals. By examining their chemical properties, production methods, applications, and safety considerations, we can better understand their distinct roles in chemistry and industry.

Chemical Overview

Cyclohexane

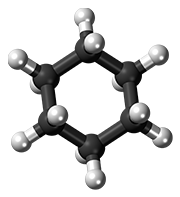

Cyclohexane has the chemical formula C₆H₁₂ and is classified as a cycloalkane, a saturated hydrocarbon with no functional groups beyond the carbon-hydrogen bonds. Its CAS number is 110-82-7. Physically, it is a colorless, flammable liquid with a distinctive detergent-like or gasoline-like odor.

The skeletal structure of cyclohexane consists of a six-membered carbon ring where each carbon is bonded to two hydrogens, forming a closed loop with all single bonds. The molecule typically adopts a chair conformation, which minimizes strain by positioning the carbon atoms at tetrahedral angles of approximately 109.5°. In this stable form, hydrogen atoms alternate between axial (perpendicular to the ring plane) and equatorial (in the plane) positions.

Cyclohexanone

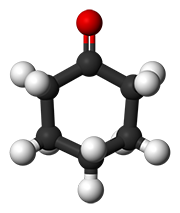

Cyclohexanone has the chemical formula C₆H₁₀O and is a cyclic ketone featuring a carbonyl group (C=O) integrated into the ring. Its CAS number is 108-94-1. It appears as a colorless oily liquid that may develop a pale yellow tint over time, with a sweet, peppermint- or acetone-like odor.

The skeletal structure is similar to cyclohexane but replaces two hydrogens with a double-bonded oxygen on one carbon, creating the ketone functionality. The ring remains six-membered, but the presence of the carbonyl introduces some planarity around the C=O bond, leading to a slightly distorted chair-like conformation.

Key Differences: Side-by-Side Comparison

For a quick reference, the following table highlights the primary differences between cyclohexane and cyclohexanone based on their chemical and physical properties:

| Property | Cyclohexane | Cyclohexanone |

| Chemical Formula | C₆H₁₂ | C₆H₁₀O |

| Functional Group | None (saturated hydrocarbon) | Ketone (C=O) |

| Molecular Weight | 84.16 g/mol | 98.15 g/mol |

| Appearance | Colorless liquid with gasoline-like odor | Colorless liquid (may yellow over time) with acetone- or peppermint-like odor |

| Boiling Point | ~81 °C (80.74 °C precisely) | ~156 °C (155.65 °C precisely) |

| Density | 0.774 g/cm³ (at 20 °C) | 0.948 g/cm³ (at 20 °C) |

| Solubility in Water | Insoluble (immiscible) | Slightly soluble (8.6 g/100 mL at 20 °C) |

| Flammability | Highly flammable (flash point -20 °C) | Flammable (flash point 44 °C) |

| Major Role | Feedstock for oxidation to nylon precursors | Direct precursor in nylon production (via caprolactam or adipic acid) |

| Molecule Chair Ball |  |  |

These differences arise primarily from the presence of the oxygen atom in cyclohexanone, which increases polarity, molecular weight, and intermolecular forces, leading to higher boiling points and densities.

Industrial Production

Cyclohexane is primarily obtained from petroleum refining through fractional distillation of naphtha fractions, often combined with isomerization processes to convert related compounds like methylcyclopentane. A significant modern method involves the catalytic hydrogenation of benzene using a Raney nickel catalyst, which is highly exothermic and produces high-purity cyclohexane.

Cyclohexanone is mainly produced by the air oxidation of cyclohexane, catalyzed by cobalt salts, yielding a mixture of cyclohexanone and cyclohexanol known as "KA oil" (ketone-alcohol oil). This process accounts for the bulk of industrial output. Alternative routes include the partial hydrogenation of phenol or innovative processes like the hydroalkylation of benzene to cyclohexylbenzene, followed by oxidation and cleavage to yield cyclohexanone and phenol.

The two compounds are intrinsically linked: cyclohexanone is derived directly from cyclohexane in most industrial settings, underscoring their sequential roles in chemical supply chains.

Applications

Cyclohexane

Cyclohexane is widely used as a non-polar solvent in industrial processes, such as in coatings, adhesives, and recrystallization techniques. Its primary role, however, is as a starting material for producing adipic acid and caprolactam, essential precursors for nylon-6,6 and nylon-6. It also serves as a reference solvent in laboratories and in specialized applications like calibrating differential scanning calorimetry instruments due to its well-defined phase transitions.

Cyclohexanone

Cyclohexanone is a key intermediate in the synthesis of nylon, where it is converted to caprolactam for nylon-6 or further oxidized to adipic acid for nylon-6,6. It functions as a solvent in paints, coatings, resins, and adhesives, benefiting from its ability to dissolve a range of polymers. Additionally, it is used in the production of pharmaceuticals, agrochemicals, and even in niche reactions like enamine formation or as a precursor for certain illicit substances (though this is not a legitimate application).

Safety & Handling

Both compounds are flammable and require careful handling, but their risks differ due to chemical reactivity.

Cyclohexane is highly flammable with a low flash point (-20 °C) and can cause narcotic effects upon inhalation, leading to drowsiness or dizziness. It is an environmental hazard as a volatile organic compound (VOC) and may be fatal if aspirated. Safe practices include storing in tightly closed containers away from ignition sources, using personal protective equipment (PPE) like gloves and respirators, and ensuring good ventilation. Exposure limits include a NIOSH recommended limit of 300 ppm.

Cyclohexanone is also flammable (flash point 44 °C) but is more irritating to eyes, skin, and respiratory tracts due to its carbonyl group, which increases chemical reactivity. It is moderately toxic and can cause serious eye damage. Handling guidelines emphasize PPE, avoiding skin contact, and spill control with absorbents. Its threshold limit value is 25 ppm, and it should be stored in cool, well-ventilated areas.

In both cases, fire suppression should use foam, dry chemical, or carbon dioxide, and spills require immediate evacuation if vapors are present.

Conclusion

In summary, cyclohexane is a straightforward saturated hydrocarbon serving as a foundational feedstock in industrial chemistry, while cyclohexanone is its functionalized ketone derivative, playing a more direct role as an intermediate in nylon production. Though structurally similar and interconnected through oxidation processes, their differences in polarity, reactivity, and applications make them suited for distinct purposes. Understanding these compounds highlights the efficiency of modern chemical manufacturing. For further technical details or supply options, readers are encouraged to explore product pages on cyclohexanone from reputable chemical suppliers.

FAQ

Is cyclohexanone derived from cyclohexane?

Yes, industrially, cyclohexanone is primarily produced by the catalytic air oxidation of cyclohexane, resulting in KA oil that contains both cyclohexanone and cyclohexanol.

Which is more flammable, cyclohexane or cyclohexanone?

Cyclohexane is more flammable due to its lower flash point (-20 °C) compared to cyclohexanone (44 °C), making it more prone to ignition at ambient temperatures.

What is cyclohexane mainly used for?

Cyclohexane is mainly used as a feedstock for producing adipic acid and caprolactam, which are precursors to nylon, and as a non-polar solvent in various industrial applications.

Why is cyclohexanone important in nylon manufacturing?

Cyclohexanone is crucial as it is converted to caprolactam (for nylon-6) via oxime formation and Beckmann rearrangement, or oxidized to adipic acid (for nylon-6,6), forming the backbone of nylon production.