1. Introduction

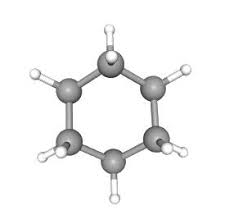

Cyclohexane is a colorless, flammable liquid hydrocarbon with the chemical formula C6H12, consisting of a six-carbon ring saturated  with hydrogen atoms. As a key industrial chemical, it is primarily derived from petroleum refining and serves as a foundational building block in various manufacturing processes. One of its most significant roles is as a feedstock in the production of nylon, a versatile synthetic polymer.

with hydrogen atoms. As a key industrial chemical, it is primarily derived from petroleum refining and serves as a foundational building block in various manufacturing processes. One of its most significant roles is as a feedstock in the production of nylon, a versatile synthetic polymer.

In nylon production, cyclohexane is oxidized to produce intermediates like adipic acid and caprolactam, which are essential for synthesizing different types of nylon. Nylon, first developed in the 1930s, revolutionized materials science and remains crucial today. It is widely used in textiles for durable fabrics like stockings, parachutes, and outdoor gear; in plastics for components such as gears and bearings; and in engineering materials for automotive parts, electrical insulators, and high-strength ropes. Its combination of strength, elasticity, and resistance to abrasion makes it indispensable across industries, contributing to everything from everyday clothing to advanced engineering applications.

2. The Role of Cyclohexane in Chemical Industry

Cyclohexane plays a multifaceted role in the chemical industry, valued for its stability and reactivity under controlled conditions. It is commonly used as a non-polar solvent in paints, adhesives, and extraction processes, as well as in the production of other chemicals like cyclohexanol and cyclohexanone. Additionally, it serves as a raw material in the synthesis of pesticides, pharmaceuticals, and rubber chemicals.

However, one of its largest and most economically impactful applications is in nylon production. Globally, a substantial portion—estimated at over 80%—of cyclohexane consumption is directed toward this purpose. This dominance stems from cyclohexane's efficient conversion into nylon precursors, supporting a multi-billion-dollar industry that produces millions of tons of nylon annually.

3. From Cyclohexane to Adipic Acid and Caprolactam

The transformation of cyclohexane into nylon involves a series of chemical reactions that highlight its value as a feedstock. The primary pathways are as follows:

Cyclohexane to Adipic Acid (for Nylon-6,6)

Cyclohexane is first oxidized in the presence of air and a cobalt or manganese catalyst at elevated temperatures to form a mixture known as KA oil (cyclohexanol and cyclohexanone). This mixture is then further oxidized with nitric acid to produce adipic acid (C6H10O4). Adipic acid is a dicarboxylic acid that serves as one of the two monomers for Nylon-6,6.

Cyclohexane to Caprolactam (for Nylon-6)

Starting similarly with cyclohexane oxidation to cyclohexanone (via KA oil), cyclohexanone is then converted to cyclohexanone oxime through reaction with hydroxylamine. This oxime undergoes the Beckmann rearrangement in the presence of sulfuric acid to yield caprolactam (C6H11NO), a cyclic amide that is the sole monomer for Nylon-6.

Simplified Reaction Flow

Cyclohexane (C6H12) → [Oxidation] → Cyclohexanol/Cyclohexanone (KA oil)

Path 1: KA oil → [Nitric Acid Oxidation] → Adipic Acid → [with Hexamethylenediamine] → Nylon-6,6

Path 2: Cyclohexanone → [Oxime Formation & Beckmann Rearrangement] → Caprolactam → Nylon-6

These processes are conducted on an industrial scale, with careful control to maximize yields and minimize byproducts.

4. Nylon Manufacturing and Applications

Nylon-6,6 Synthesis

Adipic acid reacts with hexamethylenediamine (H2N-(CH2)6-NH2) in a polycondensation reaction, where the carboxylic acid groups of adipic acid link with the amine groups of hexamethylenediamine, releasing water and forming long polymer chains. The resulting polymer, Nylon-6,6, has repeating units of six carbons from each monomer.

Nylon-6 Synthesis

Caprolactam undergoes ring-opening polymerization, typically initiated by water or acids at high temperatures. The seven-membered ring opens, and the molecules link to form linear polyamide chains, creating Nylon-6 with repeating units of six carbons.

Applications of Nylon

Textiles: Clothing, carpets, upholstery, sportswear; durable and moisture-wicking.

Automotive: Engine components, tire cords, fuel lines; heat resistance and strength.

Packaging: Films and bottles with barrier properties against gases and odors.

Engineering Plastics: Gears, bearings, electrical connectors; toughness and low friction.

These uses underscore nylon's role in modern manufacturing, with annual global production exceeding 8 million tons.

5. Advantages of Cyclohexane as a Feedstock

High availability: Produced at scale from petroleum refining (e.g., naphtha reforming) for stable supply.

Process maturity: Established pathways to adipic acid and caprolactam with optimized conversions.

Reliability: Consistent outputs under controlled reaction conditions; suitable for large plants.

Cost-effectiveness: Competitive value chain that supports nylon’s broad adoption across industries.

6. Safety, Handling, and Sustainability Considerations

While cyclohexane is essential, it requires careful management due to its properties. It is highly flammable with a low flash point, and its vapors can form explosive mixtures with air. Responsible handling includes storing it in well-ventilated areas away from ignition sources, using appropriate personal protective equipment, and following regulations like those from OSHA or REACH for safe transportation and use.

On the sustainability front, the industry is advancing green chemistry initiatives. For instance, traditional adipic acid production generates nitrous oxide (N2O), a potent greenhouse gas, but newer processes incorporate catalytic technologies to capture or reduce emissions. Efforts also focus on bio-based alternatives and recycling nylon to lessen environmental impact, aligning with global goals for circular economies.

7. Conclusion and Call to Action

In summary, cyclohexane stands as an indispensable feedstock in nylon production, enabling the creation of adipic acid and caprolactam that form the backbone of Nylon-6,6 and Nylon-6. Its role supports industries vital to daily life and technological progress, from textiles to engineering.

For businesses and manufacturers seeking reliable materials, we encourage sourcing high-quality cyclohexane from reputable suppliers to ensure optimal performance and safety in your production processes. Explore partnerships that prioritize sustainability to future-proof your operations.

Looking for a reliable bulk supplier of Cyclohexane?

Aure Chemical provides Premium Cyclohexane raw materials.

View our Cyclohexane product page