Tetrahydrofuran (CAS 109-99-9): Properties, Purification, Uses, Precautions

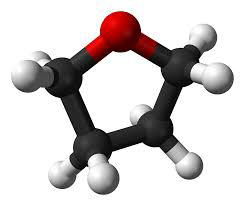

Tetrahydrofuran, commonly abbreviated as THF, is an important organic compound with the chemical formula C4H8O. This colorless, transparent liquid is a vital intermediate in various chemical processes. This article provides a detailed overview of its properties, applications, and important safety considerations.

Basic Properties

Tetrahydrofuran (THF), with the chemical formula C4H8O, is a colorless, transparent liquid. It has an ether-like scent similar to ethanol and is soluble in water and many organic solvents. It is an important intermediate for organic synthesis and is widely used in the chemical industry.

Physical Properties

|

|

Chemical Properties

It generates explosive peroxides in the air due to auto-oxidation. Oxidation with nitric acid produces succinic acid. Under the catalysis of aluminum oxide, it reacts with ammonia at 300-400℃ to yield pyrrolidine. It reacts with hydrogen sulfide at 400℃ to produce tetrahydrothiophene. In the presence of zinc chloride and under the action of acids or acid chlorides, it easily undergoes ring-opening to form 1,4-butanediol and 1,4-dihalides. Under the influence of light, chlorination at room temperature produces 2,3-dichlorotetrahydrofuran. The chlorine atom at the second position is very active and can be directly replaced by alkoxy, acetate, or alkyl groups from Grignard reagents. Using an acidic phosphate as a catalyst, THF dehydrates at 270℃ to form butadiene. When heated, tetrahydrofuran reacts with hydrogen chloride gas, rearranging to form 4-chlorobutanol.In the presence of aluminum trichloride, tetrahydrofuran reacts quantitatively with lithium aluminum hydride to produce butanol.

Purification Methods

Tetrahydrofuran can be obtained by the dehydration of 1,4-butanediol or the hydrogenation of furan. Besides impurities from the manufacturing process, it also contains various antioxidants added to prevent auto-oxidation. Before purification, it is necessary to check for the presence of peroxides; otherwise, distillation or heating evaporation cannot be performed to avoid explosions. The method for testing for peroxides is the same as for diethyl ether and can be done with a 2% acidic potassium iodide solution. Peroxides can be removed by treating the THF with a mixed aqueous solution of ferrous sulfate and sodium bisulfate. Alternatively, peroxides can be removed by passing the tetrahydrofuran through activated alumina. A common purification method is to reflux tetrahydrofuran with lithium aluminum hydride and then distill it in the presence of lithium aluminum hydride to remove water, peroxides, antioxidants, and other impurities. Both refluxing and distillation should be carried out under a nitrogen stream. A small amount should be tested first to ensure that the water and peroxide content is not high and the reaction is not too violent before proceeding. After removing peroxides, it can also be purified by drying with calcium chloride or anhydrous sodium sulfate, followed by filtration and fractional distillation.

Solubility Properties

Tetrahydrofuran is miscible with water. The azeotropic mixture it forms with water is able to dissolve cellulose acetate and alkaloids like caffeine, and the solubility is better than using THF alone. Common organic solvents such as ethanol, diethyl ether, aliphatic hydrocarbons, aromatic hydrocarbons, and chlorinated hydrocarbons are all well-dissolved in tetrahydrofuran.

Solubility of Resin in Tetrahydrofuran

| Soluble Resin | Swelling or Partially Soluble Resin | Insoluble Resin |

Hydrocarbons

| Styrene-butadiene rubber Chloroprene rubber | Polyethylene, Polypropylene Fluororesin Polysulphide rubber Triacetic cellulose (ester) |

*Partially insoluble

Uses of Tetrahydrofuran

Tetrahydrofuran is an excellent organic solvent. It is widely used due to its fast dissolving speed and good penetration and diffusion into the surface and interior of resins. It is particularly used for dissolving polyvinyl chloride, polyvinylidene chloride, and their copolymers to obtain low-viscosity solutions, and is therefore used in the manufacture of surface coatings, protective coatings, adhesives, and films. It is also used in inks, paint removers, extraction agents, and artificial leather surface treatment agents. It can be used as a solvent in Grignard reactions, polymerization reactions, LiAlH₄ reduction condensation reactions, and esterification reactions. Tetrahydrofuran is also an intermediate for the production of butadiene, nylon, poly(butylene glycol) ether, γ-butyrolactone, polyvinylpyrrolidone, and tetrahydrothiophene.

Precautions for Use

It is a Class 1 flammable liquid. RIDADR: UN 2056. It is non-corrosive to metals and can be stored in containers made of iron, mild steel, copper, or aluminum. Gaskets, linings, and seals must be carefully selected, as tetrahydrofuran is corrosive to many plastics and rubbers. Due to its low boiling point and flash point, it is easily ignited at room temperature and should be kept away from ignition sources. When stored, oxygen in the air can react with tetrahydrofuran to form explosive peroxides. Peroxides are more easily formed under the influence of light and in the absence of water. Therefore, reducing substances such as hydroquinone, resorcinol, p-cresol, or ferrous salts are often added at a concentration of 0.05-1% (wt) as antioxidants to inhibit the formation of peroxides. Storing it in a sealed container filled with nitrogen in a cool place can also prevent the formation of peroxides. Tetrahydrofuran is classified as slightly toxic by inhalation and low toxicity orally. It has an irritating effect on the mucous membranes of the eyes, nose, and tongue. Its vapor has an anesthetic effect, and prolonged inhalation of high concentrations can cause symptoms such as dizziness, lightheadedness, headaches, and vomiting. When the concentration in the blood reaches 160 mg/kg, it can lead to complete anesthesia; at 300-400 mg/kg, it can be fatal. However, the toxicity of the pure product is lower than that of acetone, making it one of the least toxic solvents. The olfactory threshold concentration is 30 ppm, and the maximum permissible concentration in the workplace is 200 ppm (590 mg/m³). When the concentration is greater than 25-50 ppm, the characteristic odor of tetrahydrofuran can be felt.

Looking for a reliable bulk supplier of Tetrahydrofuran (CAS 109-99-9)?

Aure Chemical provides Premium Tetrahydrofuran (CAS 109-99-9) raw materials.

View our Tetrahydrofuran (CAS 109-99-9) product page