Industrial Synthesis and Manufacturing Process of BF₃·Pip

Boron Trifluoride Piperidine Complex, commonly known as BF₃·Pip and identified by CAS number 592-39-2, is a specialized Lewis acid catalyst that's like a reliable toolbox in  the chemist's workshop—versatile, stable, and essential for precise reactions. This compound plays a vital role in industries such as organic synthesis, pharmaceuticals, polymers, and agrochemicals, where it facilitates efficient chemical transformations. Unlike pure boron trifluoride (BF₃), which is a gas and can be as unpredictable as a loose cannon, the piperidine complex offers easier handling and controlled reactivity. This blog post dives into its industrial synthesis and manufacturing process, highlighting the steps that make it a go-to ingredient for high-performance applications.

the chemist's workshop—versatile, stable, and essential for precise reactions. This compound plays a vital role in industries such as organic synthesis, pharmaceuticals, polymers, and agrochemicals, where it facilitates efficient chemical transformations. Unlike pure boron trifluoride (BF₃), which is a gas and can be as unpredictable as a loose cannon, the piperidine complex offers easier handling and controlled reactivity. This blog post dives into its industrial synthesis and manufacturing process, highlighting the steps that make it a go-to ingredient for high-performance applications.

Chemical Properties of BF₃·Pip

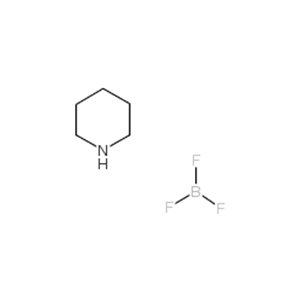

BF₃·Pip has the molecular formula C₅H₁₁BF₃N, formed by the coordination of BF₃ with piperidine, a six-membered ring amine—picture it as BF₃ "hugging" the nitrogen atom in piperidine for stability.

It's a white to off-white crystalline solid with a melting point of 71-73°C and a boiling point around 106°C at 760 mmHg. The complex is soluble in organic solvents like ethanol and acetone but reacts with water, releasing BF₃. Complexing BF₃ with piperidine enhances safety by reducing volatility and corrosiveness, while maintaining strong Lewis acidity for selective catalysis—much like taming a wild spice to add just the right kick to a recipe without overwhelming it.

Raw Materials Required

The synthesis of BF₃·Pip relies on straightforward raw materials. Key components include:

Boron Trifluoride (BF₃): Often supplied as a gas or in complexed form like BF₃ etherate (BF₃·OEt₂), which is easier to handle in industrial settings.

Piperidine: A colorless liquid amine (C₅H₁₁N) with a purity of at least 99% for optimal complex formation.

Solvents: Optionally, inert solvents like diethyl ether or dichloromethane to control the reaction and prevent overheating.

Purity is crucial—BF₃ should be anhydrous to avoid hydrolysis, and piperidine free of impurities to ensure high-yield complexation. For large-scale production, sourcing from reliable suppliers focuses on cost-effective, high-purity grades to minimize downstream purification needs.

Industrial Synthesis Methods

4.1 Direct Complexation

The primary method involves direct reaction of BF₃ with piperidine in equimolar proportions: BF₃ + C₅H₁₀NH → BF₃·C₅H₁₀NH. Gaseous BF₃ is bubbled into liquid piperidine or its solution in an inert solvent, like slowly pouring soda into a glass to avoid fizz overflow. Conditions include temperatures of 0-50°C to manage exothermic heat, atmospheric pressure, and stirring for uniform mixing. This liquid-phase approach is simple and scalable for industry.

4.2 Alternative Methods

An alternative uses BF₃ etherate, where BF₃·OEt₂ reacts with piperidine in dichloromethane, displacing the ether: BF₃·OEt₂ + C₅H₁₀NH → BF₃·C₅H₁₀NH + OEt₂. This is preferred when handling pure BF₃ gas is challenging. Advantages include better control and higher purity, but it may require additional solvent recovery, increasing costs compared to direct gas-phase bubbling.

Manufacturing Process Flow

Industrial production follows a streamlined flow, adaptable for batch or continuous operations.

Preparation of BF₃: BF₃ gas is generated or sourced from cylinders; if using etherate, it's dissolved in solvent.

Complexation with Piperidine: Piperidine is charged into a reactor under inert atmosphere. BF₃ is introduced slowly with cooling (30-50°C) and stirring (2-5 hours) to form the complex.

Purification and Isolation: The mixture is cooled to 15-20°C for crystallization, followed by centrifugation to separate solids. Mother liquor is recycled.

Drying and Packaging: Crystals are vacuum-dried at 35-45°C for 3-5 hours, then packaged in sealed containers under dry conditions to prevent moisture.

This process ensures high yields (90%+) with minimal waste.

Quality Control in Production

Quality is monitored through parameters like purity (≥98%), water content (<0.5%), and BF₃ content (around 43%). Techniques include gas chromatography (GC) for impurities, nuclear magnetic resonance (NMR) for structure confirmation, infrared spectroscopy (IR) for bonding, and titration for acid content—like taste-testing a soup for the perfect balance. Compliance with standards like ISO ensures suitability for industrial use.

Safety and Environmental Considerations

BF₃·Pip is corrosive and can release toxic BF₃ fumes, so handling requires PPE like gloves, goggles, and respirators, plus well-ventilated areas. Industrial setups use scrubbers for emissions and recycle solvents to minimize waste. Regulations from bodies like EPA demand proper waste treatment, turning potential hazards into managed byproducts—like channeling a river to prevent flooding.

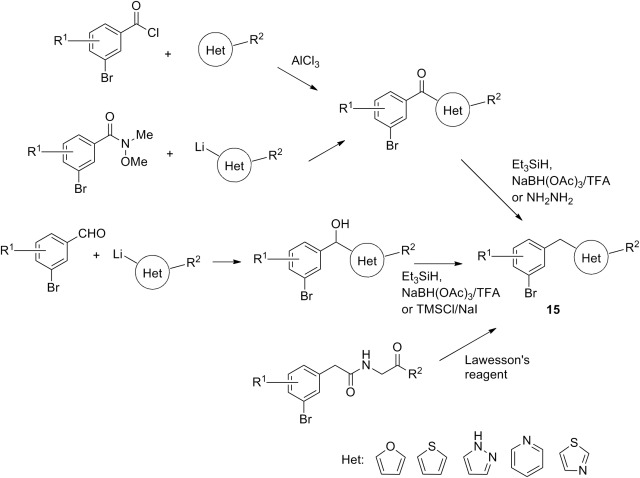

Applications Linked to Manufacturing

High-purity BF₃·Pip from this process enhances downstream uses. In pharmaceuticals, it catalyzes selective API synthesis, reducing impurities for safer drugs. For polymers, controlled production ensures consistent catalysis in resin formation, yielding durable materials. In agrochemicals, it boosts efficiency in pesticide intermediates, supporting eco-friendly formulations. The manufacturing focus on purity directly translates to better performance and cost savings in these fields.

Conclusion

The industrial synthesis of BF₃·Pip (CAS 592-39-2) centers on efficient complexation of BF₃ with piperidine, emphasizing safety, quality, and scalability through steps like reaction, crystallization, and drying. By prioritizing these factors, manufacturers deliver a reliable catalyst for diverse applications. If you're interested in sourcing or learning more, visit our product page or submit an inquiry today!

Related Articles

Looking for a reliable bulk supplier of Boron Trifluoride Piperidine Complex?

Aure Chemical provides Premium Boron Trifluoride Piperidine Complex CAS 592-39-2.

View our Boron Trifluoride Piperidine Complex product page